Shaped Steel Laser Cutting

If your shop processes shaped steel—H-beams, I-beams, channel, angle, and other structural sections—you already know the hidden cost isn’t only “cut time.” It’s the number of separate steps you need to finish one part: cutting, drilling/perforation, bevel prep, marking/lining, and constant handling between stations.

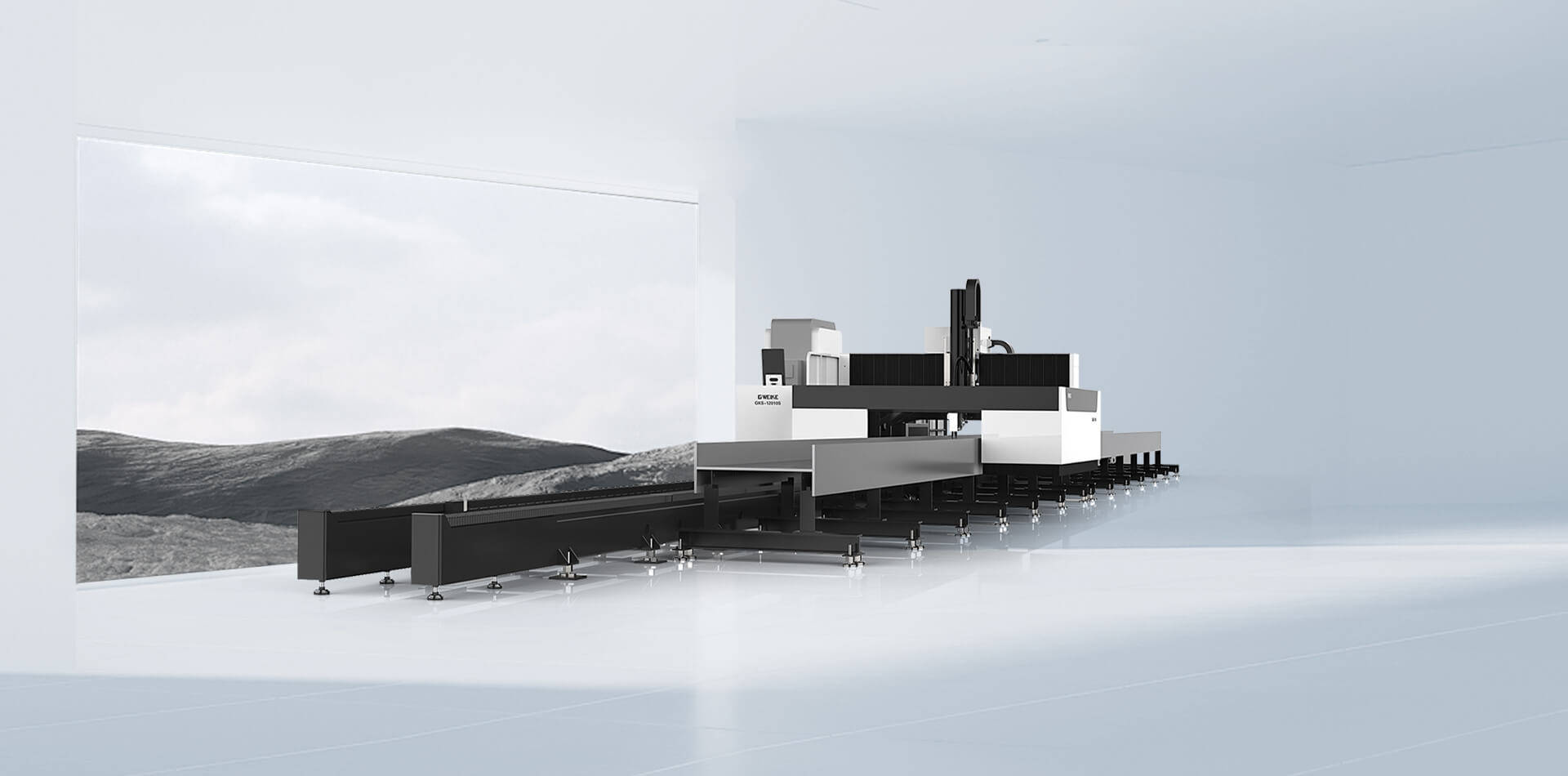

That is why more steel structure and heavy fabrication shops are shifting toward all-in-one shaped steel laser cutting machines that combine multiple operations in a single setup—such as a cantilever-style system and a gantry-style system.

This article explains (in plain English) what these systems actually solve, and how to choose between cantilever and gantry architectures based on your real workflow.

Why Shaped Steel Is a Different World Than Sheet Metal

Sheet cutting is mostly about speed, nesting, and handling sheets safely. Shaped steel adds three practical challenges:

Geometry variety: web + flange surfaces, different widths, different heights, mixed profiles.

Multi-process reality: a finished part often needs holes, slots, bevels, and marks—not just a cut edge.

Handling cost: long sections are heavy, difficult to align repeatedly, and easy to damage or distort.

Every time you move a beam from one station to another, you add:

crane/forklift time,

alignment time,

risk of dimensional drift,

and more waiting in the queue.

The strategic goal is simple: reduce handling and combine steps.

What “All-in-One” Really Means (And Why It Matters)

Both the cantilever and gantry shaped-steel systems above position themselves as “all-in-one” machines: cutting, perforating, beveling, locking, marking, and lining up performed on one platform. (GWEIKE)

In real production terms, that combination can replace several traditional stations:

saw cutting,

drill line / punching,

manual bevel grinding,

manual marking and layout.

You don’t buy this to “cut faster.” You buy it to eliminate downstream work and make assemblies fit with less rework.

Tekla “One-Click Nesting”: The Fastest Way to Reduce Programming Friction

In steel structure work, the biggest time drain is often not cutting—it’s preparing drawings, separating files, and translating design intent into shop-floor instructions.

Both systems highlight Tekla one-click nesting—supporting TEKLA 3D modeling data for cutting without needing separate drawings, enabling faster, more intelligent nesting.

What this means in practical terms:

Less time doing “draw-to-shop” conversion work.

Fewer manual interpretation mistakes.

Faster changeover between projects, especially in project-based construction work.

If your shop already runs Tekla (or receives Tekla-based files), this is a major lever for throughput.

Real-Time Compensation: Why Long Parts Stay More Consistent

Shaped steel has thermal behavior and deformation realities. One of the points emphasized is real-time compensation, including contour detection and real-time data to compensate for deformation areas, aiming to reduce thermal deformation and keep cross-sections smoother.

The plain-English takeaway:

When you cut long sections or complex features, distortion risk grows.

Compensation and monitoring features can reduce “why doesn’t this fit?” situations later in welding/assembly.

This matters most when your work includes long runs, heavier sections, and tighter fit-up expectations.

Cantilever vs Gantry: How the Architecture Changes Your Daily Workflow

Here is the key difference that buyers should focus on: how the machine moves and how your operators load/unload.

Cantilever-style shaped steel cutting (practical loading and open access)

A cantilever approach emphasizes an open cutting table and easier access, with messaging around reducing labor cost for loading/unloading.

Choose a cantilever direction when:

you value easy loading/unloading and access around the work zone,

your shop prefers a simpler “bring the steel in, process it, take it out” flow,

you want strong capability without building a highly structured production line.

This is often attractive for mixed job shops that do steel structure work but still live in a flexible, project-based environment.

Gantry-style shaped steel cutting (stable bed structure and broader processing flexibility)

A gantry approach emphasizes a gantry bed structure and a mobile processing method for flexible cutting actions.

Choose a gantry direction when:

your work is more production-like and you want stable dynamics and process repeatability,

you handle a wide range of section sizes and want quick adjustment for different widths (the page highlights an instant adjustment mechanism for different width profiles).

you want a system that feels like a heavier “production asset” in a structured workflow.

A Major Differentiator: Section Steel + Plate Dual-Use

The gantry-type page also highlights plate & section steel dual-use—supporting both section steel and plate processing so one equipment can cover multiple needs.

This matters if your workflow looks like:

structural members + gusset plates,

beams + connector plates,

brackets + stiffeners.

In those shops, a dual-use concept can reduce the need to move work between separate plate and section stations—again, saving handling time and scheduling friction.

Extra-Long Work Areas and Double Workstations: When Scale Matters

Both pages emphasize an extra-large processing area with modular design and a double workstation up to 25.5 meters long for large-scale processing.

What to do with this information:

If you regularly process long members and want consistent throughput, you should evaluate not only the machine—but also your material staging, crane paths, and finished-part flow.

Large work areas deliver value only when your shop is organized to feed them.

Buyer Checklist: What to Prepare Before You Request Quotes

To get an accurate recommendation (and avoid a mismatch), prepare:

Your top 10 profiles (type + sizes) and typical lengths

Your top 10 parts: which need holes, bevels, marking, or special features

Your production mode: project-based / batch / repeat

How you handle steel today: crane/forklift type, staging space, and part exit flow

Your biggest pain point: handling time, rework, drilling time, bevel prep time, or programming time

This information is more valuable than asking “What’s the max thickness?”

FAQ

Is an all-in-one shaped steel laser worth it if we already have a drill line?

Often yes if your bottleneck is handling and rework. The value is in fewer setups, fewer transfers, and more consistent fit-up—not only replacing drilling.

What if we don’t use Tekla?

You can still benefit from multi-process integration, but the Tekla workflow advantage is most meaningful when your upstream design process already produces compatible 3D data.

What’s the most common reason these big systems “feel slow” after purchase?

Factory flow. If staging, crane routes, and finished-part sorting are not planned, the machine will wait for material handling—no matter how capable it is.

Closing

In steel structure production, the real throughput gains come from reducing steps and reducing handling, not only increasing cutting speed. An all-in-one shaped steel laser platform—whether cantilever or gantry is fundamentally a workflow upgrade: it helps you cut, perforate, bevel, and mark in one setup, then move parts downstream with fewer surprises.

Post Your Ad Here

Comments