How Plastic Injection Moulding Is Conducted?

by Justin Langer Content ManagerThe procedure most often referred to as "Injection Moulding" is one of the most widely employed in the manufacturing of plastic goods. The method of plastic injection molding is quite popular for a number of reasons, but one of the most often cited ones is the fact that it can be used to make vast amounts of similarly shaped plastic things for a variety of uses. Simple, throwaway consumer items to crucial, highly precise engineering components are all products of this process.

The Basic Method

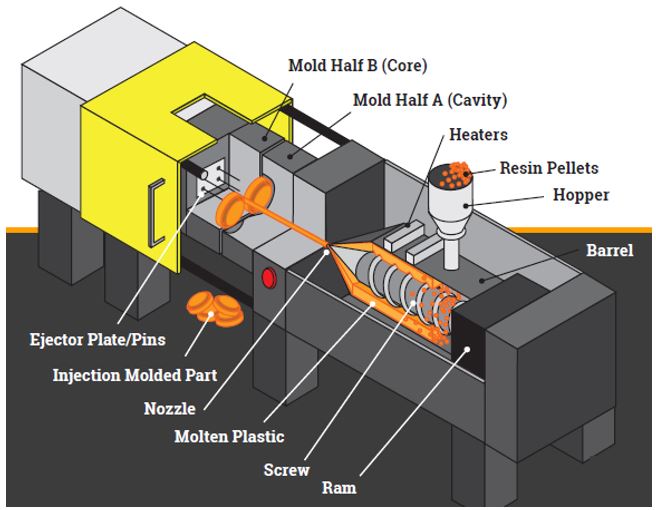

In its simplest form, the procedure for plastic injection molding is feeding a specific material into the molding device (usually through a "hopper"). The heated barrel is the most typical component of the moulding machine (equipped with a reciprocating screw, usually driven by a hydraulic or an electric motor, which usually then feeds molten plastic into a temperature controlled split mould via a comprehensive network of gates and runners).

The reciprocating screw melts the polymer while simultaneously serving as a ram throughout the injection operation. Before the polymer is injected into a mould that has been made in line with the necessary dimensions of the completed product demanded by the client or customer, the revolving screw's shearing effect on the plastic helps to provide even more heat that may be used in this step of the process. Depending on the material being used in the procedure, the pressure involved in the manufacturing process when the polymer is injected into the mould might potentially approach 1000 atmospheres.

Numerous businesses and organizations focus on making significant plastic parts and products using the injection moulding technique. Additionally, there are a lot of businesses that produce and provide the molds needed for the injection molding process.

The fact that the service offered by businesses using the process is highly sought after by a sizable number of customers, including those in specialized industries like aerospace and defense that require essential specialized plastic goods and items produced by this process, demonstrates the significance of the plastic injection molding process. The majority of thermoplastics, including nylon and polystyrene, are most often produced using this method.

Once the design has been finalized and approved by manufacturers, it can be sent off for production with an injection moulding service provider in order to produce the final product.

Sponsor Ads

Created on Dec 15th 2022 22:09. Viewed 153 times.