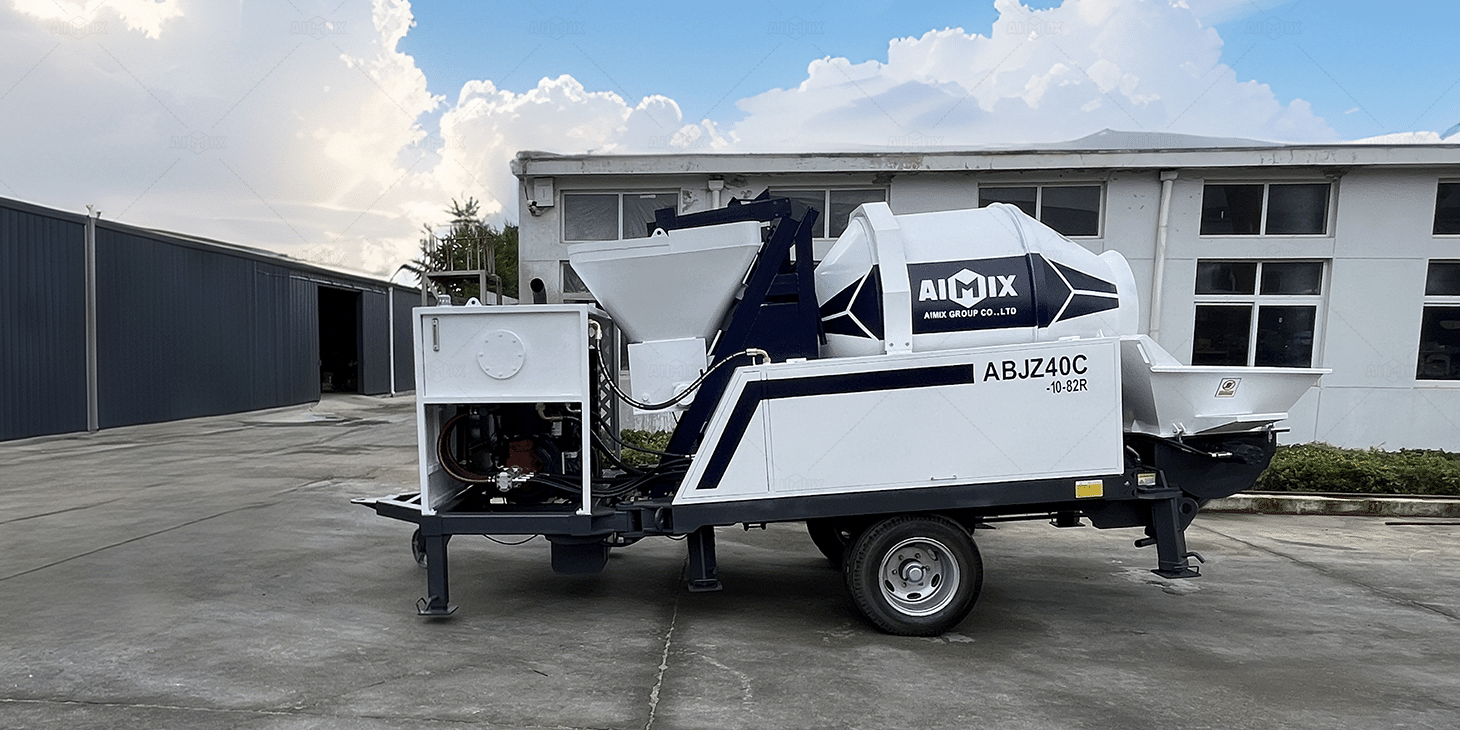

Out Of The Box And Ready To Use: A Simple Operating Experience With Portable Concrete Mixer Pump

You know, there's a good deal of talk these days about advanced technology in construction equipment. It can be overwhelming. Sometimes, what you need isn't the most complex machine, but the most sensible one. That's the thinking behind a modern portable concrete mixer with pump. It's a piece of equipment that values practicality over pretense, designed not to impress with jargon but to perform with reliability. The idea is straightforward: combine batching, mixing, and pumping into a single, mobile unit that minimizes fuss and maximizes productivity. For the contractor who prefers solutions that just work, this approach offers a refreshing and highly effective alternative to the old way of doing things. Let's walk through what makes this operating experience so uniquely straightforward.

Getting Started: Simplicity from the Ground Up

The first test of any machine is how easily you can get it running. With a well-designed portable cement mixer pump, the setup is refreshingly uncomplicated. Delivery is often a simple tow to the site behind a standard truck. Once in position, the process doesn't require a team of specialists or days of foundation work. The machine sits on its own stable chassis. You'll connect a water source, which can be as simple as a standard hose, and ensure you have your piles of aggregate and sand, along with bags or a silo of cement, within reach of the machine's loading hopper. The control panel is typically laid out in a clear, logical manner. Within a short time—often less than an hour from arrival—you can be ready to produce the first batch. There's a certain virtue in this lack of ceremony. It gets you from transport to production with a minimum of delay and complication, which is how most profitable workdays begin.

The Seamless Workflow: Mixing and Placing in One Continuous Motion

Where this machine truly proves its worth is in the daily rhythm of the job. The old method involved a disjointed sequence: waiting for a ready-mix truck, coordinating its arrival with a separate pump crew, and hoping the schedules align. The portable concrete mixer pump for sale consolidates these steps. One or two men can manage the entire operation. One operator controls the loading and mixing process from the central panel, while another guides the placement hose. The machine draws its own materials, batches them precisely by weight, and mixes them thoroughly. Then, without pause, the same integrated system pumps the fresh concrete directly to where it's needed—whether that's thirty feet away at a foundation or up to the second-story slab. This continuous, self-contained workflow eliminates the bottlenecks and dependencies that plague traditional pours. You control the tempo, batch by batch. This operational autonomy is a significant advantage, reducing labor coordination and removing the uncertainty of external delivery timelines.

A Practical Machine for Real-World Demands

This isn't a machine for every single colossal project, and that's quite alright. Its strength lies in addressing a wide array of common, practical applications where its combination of features makes perfect sense. Think of the residential contractor building a series of suburban homes, or the crew working on a small commercial shop, a farm storage building, or a community swimming pool. It excels in settings where space is tight, access might be limited for large trucks, and the pour volumes are substantial but not astronomical. The machine’s portability means you can complete a foundation pour on one side of a site in the morning, then easily move it to another location in the afternoon. Furthermore, by producing concrete on demand, you drastically cut down on material waste—no more paying for leftover concrete in a truck that must be washed out. You mix what you need, when you need it. In the end, it represents a prudent investment: it solves multiple problems with one asset, reduces overhead, and returns the control of the schedule back to the contractor where it belongs. It's a testament to the idea that the best tools are often those that perform their duty with quiet, unassuming efficiency.

Advertise on APSense

This advertising space is available.

Post Your Ad Here

Post Your Ad Here