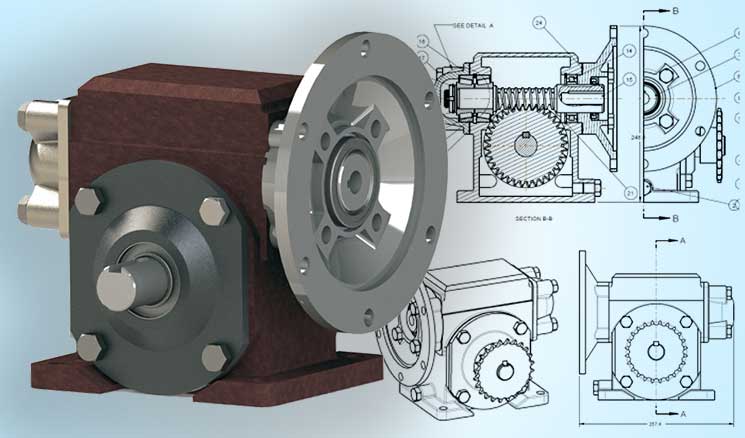

2D to 3D CAD Conversion Services for Gear Assemblies

Client: Custom Tool Equipment Manufacturer

Industry: Machine Tool Equipment Manufacturing

Location: India

Services Offered:

- 2D to 3D CAD Conversion

- 3D CAD Modeling for Manufacturing

- Detailed Engineering Drawings & BOMs

Software Used: Pro/ENGINEER Wildfire 5.0

Objectives:

The client, a reputable machine tool equipment manufacturer based in India, approached us with a requirement to convert non-editable 2D PDF drawings into intelligent, editable 3D CAD models. These files were vital for upgrading the designs of a reducer gear assembly in a steel strapping machine, aligning it with modern shop floor capabilities.

Challenges Faced:

- Loss of Design Intelligence: The PDF format lacked metadata, parametric relationships, or editable features. Extracting meaningful geometry while preserving functionality was critical.

- Short Turnaround Time: The client’s production cycle demanded quick modeling with minimal revisions.

- Manufacturing Alignment: The original 2D designs did not account for shop floor tooling constraints or adjustments.

Our Process & Technical Approach

1. Design Interpretation

Our CAD engineers conducted a comprehensive review of the 2D PDF files. Using detailed measurement analysis and input from the client’s engineering team, we rebuilt the structure and geometry in Pro/ENGINEER Wildfire 5.0.

2. Shop Floor Collaboration

We reviewed tooling and fabrication constraints to embed manufacturing intent directly into the model, especially important for sheet metal design aspects.

3. 3D CAD Model Creation

- Reconstructed all components using Pro/E’s parametric tools

- Developed assemblies, subassemblies, and features like gear mounts, strapping plates, and couplings

- Integrated feature-based modeling for easier future iterations

4. Deliverables

- Fully parametric 3D CAD assemblies

- Exploded isometric views for visual clarity

- Fabrication-ready manufacturing drawings

- Accurate Bill of Materials (BOM)

- STEP/IGES files for compatibility

Outcome & Client Value

- 35% reduction in manufacturing delays by pre-validating component interactions in 3D

- Enabled real-time collaboration between engineering and production

- Established a digital twin of the reducer assembly for continuous improvement

- Built a reusable CAD asset library

This 2D to 3D CAD conversion created a robust platform for ongoing design innovation and faster turnaround on manufacturing changes.

Check the detailed case study: 2D to 3D CAD Conversion of Reducer Gear Assembly

Post Your Ad Here

Comments