The Benefits of Utilizing Automated Tape Edge Machines in Mattress Manufacturing

by ZIMLIN Mattress Machinery Mattress MachinesMattress Manufacturing

Mattress manufacturing is an intricate process that requires precision and attention to detail. The quality of a mattress largely depends on the techniques and tools used during the manufacturing process. One important aspect of mattress production is the final step of attaching the fabric cover to the mattress, known as tape edging. Traditionally, this process was done manually, but with advancements in technology, automated tape edge machines are now widely used in the mattress manufacturing industry.

Efficiency in Mattress Production

Efficiency plays a crucial role in any manufacturing process, and the mattress industry is no exception. Automating certain tasks can greatly improve productivity while reducing costs and human error. Automated tape edge machines have revolutionized the mattress manufacturing process by speeding up the production time and improving the overall quality of the end product.

Semi-Auto Tape Edge Machine

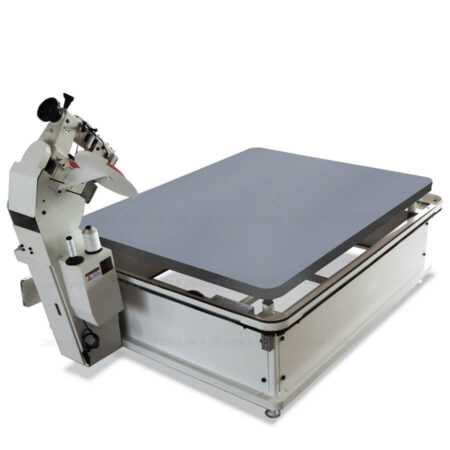

One type of tape edge machine commonly used in mattress manufacturing is the semi-automatic tape edge machine. These machines are designed to streamline the process by automating certain steps while still requiring some manual input. The operator guides the fabric through the machine, and the machine automatically sews and trims the edges. This semi-automatic process strikes a balance between efficiency and control, allowing for greater accuracy and reducing the physical strain on the operator.

The semi-automatic tape edge machine is equipped with advanced features that enable it to handle different fabric thicknesses and sizes, ensuring a consistent and precise tape edge every time. Additionally, these machines are relatively easy to operate and require minimal training for the operators.

Automatic Tape Edge Machine

For manufacturers seeking an even higher level of automation and efficiency, the automatic tape edge machine is the ideal choice. These machines are fully automated and require minimal human intervention. Once the operator sets up the machine with the necessary parameters, it can independently complete the tape edge process for multiple mattresses, further increasing productivity.

The automatic tape edge machine has advanced features such as synchronized feeding of the fabric, automatic flipping, and precise sewing technology. This ensures that the mattress cover is securely attached with uniform tension throughout, resulting in a neat and professional finish. The automated process eliminates the need for manual trimming, reducing labor costs and improving the speed of production.

ZIMLIN Mattress Machine

When it comes to choosing the right automated tape edge machine for mattress manufacturing, ZIMLIN offers top-quality solutions. ZIMLIN has been a trusted name in the mattress machinery industry for several years, and their pocket coil machine and mattress roll packing machines are known for their reliability, durability, and cutting-edge technology.

The ZIMLIN automatic tape edge machine is equipped with state-of-the-art features that ensure efficient and precise tape edging. The machine's user-friendly interface allows operators to easily adjust settings, and its robust construction guarantees long-lasting performance. ZIMLIN machines are designed to handle various mattress sizes and fabric types, making them versatile and adaptable to different production requirements.

In addition to the superior technical capabilities, ZIMLIN also provides excellent after-sales service and support. Their team of experts is readily available to assist with installation, training, and any technical issues that may arise. This commitment to customer satisfaction sets ZIMLIN apart from other manufacturers in the industry.

The Benefits

The benefits of utilizing automated tape edge machines in mattress manufacturing are abundant. Firstly, these machines significantly reduce the time required to complete the tape edging process. This leads to a higher production output, allowing manufacturers to meet customer demands more efficiently. The time saved can also be utilized for other important tasks, such as quality control and product inspection.

Secondly, automated tape edge machines ensure consistent and precise tape edging, resulting in a superior-quality product. The machines' advanced features eliminate human error, ensuring that each mattress receives the same level of craftsmanship. This consistency enhances customer satisfaction and helps build a reputable brand image.

Thirdly, automated tape edge machines improve the working conditions for operators. The manual process of tape edging can be physically demanding and time-consuming, leading to fatigue and potential injury. By automating this process, operators can focus on other aspects of production while reducing the risk of repetitive strain injuries.

Lastly, the investment in automated tape edge machines offers long-term cost savings. Though the initial investment may be higher than traditional manual methods, the reduction in labor costs and increased production efficiency quickly offset the additional expense. Additionally, the durability and reliability of mattress machines, such as those provided by ZIMLIN, ensure a longer lifespan, minimizing maintenance and replacement costs.

In conclusion, the use of automated tape edge machines in mattress manufacturing brings numerous benefits to both manufacturers and consumers. From increased efficiency and productivity to improved product quality and operator well-being, these machines have revolutionized the mattress production process. When considering an automated tape edge machine, ZIMLIN stands as a trusted and reliable partner, offering cutting-edge technology and exceptional customer support. Invest in automation and take your mattress manufacturing to new heights of success.

Sponsor Ads

Created on Sep 14th 2023 06:15. Viewed 116 times.