Strategies on selecting the ideal China mold maker

by steven cheng sales

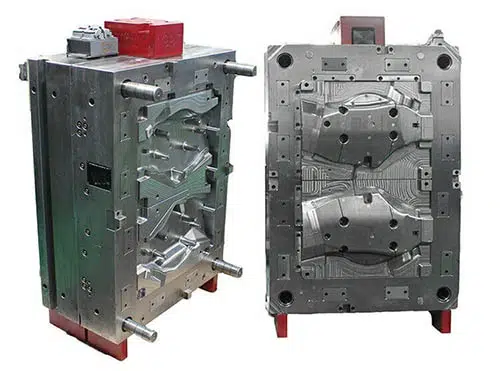

Chinese mold makers can be an ideal source for top excellent moulds for battery cases as well as paint bucket molds featuring precision engineering and affordable prices. Yet, finding a mould supplier that is located in China that has the appropriate skills requires a lot of diligence.Protect your phone on the go with a durable battery case custom designed to fit your model.

This article provides proven methods in determining trustworthy China mold makers for paint and battery case buckets. This guide offers best practices to select suppliers, setting the technical specifications, examining the samples, and managing the shipping process to overseas. It is recommended to follow this procedure to ensure.Store and transport paint easily with a sturdy plastic paint bucket manufactured to your specifications.

Researching Qualified China Mould Manufacturers

With many China mold firms to choose from, you should focus your research on these important abilities:

A vast background, extensive knowledge and experience in the battery case, or on battery cases and. Check their portfolio to find relevant instances.

* Modern machine capabilities The best moulds require expert CNC machine, EDM, and grinding abilities. Assess the shop's equipment as well as the expertise of its technicians.

have strict procedures in place and conduct thorough final inspections, carry out comprehensive inspections after each stage. Verify, check for and examine ISO Other certifications and certificates, or other ones.

* Support for engineering professionals The most reliable shops are equipped with experts in engineering who are able to optimize mold designs to ensure manufacturability as well as performance.

the delivery of moulds on time and in accordance with outstanding communication with customers.

Providing Comprehensive Design and Technical Requirements

After you've compiled a list of highly qualified China mould makers, you should provide complete specifications to enable them to provide detailed quotes:

* Incorporate product designs that include all dimensions critical to the product tolerances, dimensions, and requirements for materials.

• Specify lifecycle projections, lifecycle targets and expectations.

In the list, please indicate any requirements that require quick cycle or long-lasting durability.

Mold must comply with

Design feedback can help improve manufacturing capabilities if necessary.

The mold will be built according to your requirements. If any of the requirements are unclear, or not clearly defined.

Rigorously Evaluating Mould Designs, Prototypes, and Samples

In the course of mould design and fabrication, stay involved and engaged:

* Examine mould design and simulates to determine the possibility of manufacturing. Make any necessary adjustments.

* Check the CNC machine as well as EDM manufacturing quality during fabrication.

* Check the surface finish on the core and cavity blocks prior the assembly.

* Make sure that the prototypes you test are thoroughly tested to ensure they meet the specifications, and also under production circumstances.

Full mould completion.

Continuous progress inspections will ensure the moulds you purchase are made in accordance with the best quality requirements. The most effective China Partners welcome the chance to increase quality and improve performance.

Carefully Managing International Shipping and Logistics

Once mould production and testing are completed, supervise final stages of preparations:

* Examine the security of mould packaging solid containers

Make sure you are insured

* Check that your mold supplier is able to handle China export regulations.

For speedy clearance of customs, the country you reside in.

Plans for contingency plans in the event that delay occurs

for production.

The most important takeaways to source exceptional Moulds from China

Through rigorous supplier screening and clear specifications, as well as active quality control, and organized shipping procedures Manufacturers can purchase top quality paint bucket and battery molds from China efficient and efficiently. Keep these points in mind:

* Conduct thorough research to determine the ideal moulding supplier.

* Give detailed technical specifications and needs.

The entire fabrication process.

the logistics of logistics for delivery.

* Select a mold shop that is committed to excellence and constant improvement.

A reputable China mould maker can be an essential partner for the production of robust, high-performance molds specifically tailored to your specifications for the product. It is cost-effective, cost-effective, and efficient.

Sponsor Ads

Created on Nov 3rd 2023 02:43. Viewed 70 times.