Navigating the World of PCB Services

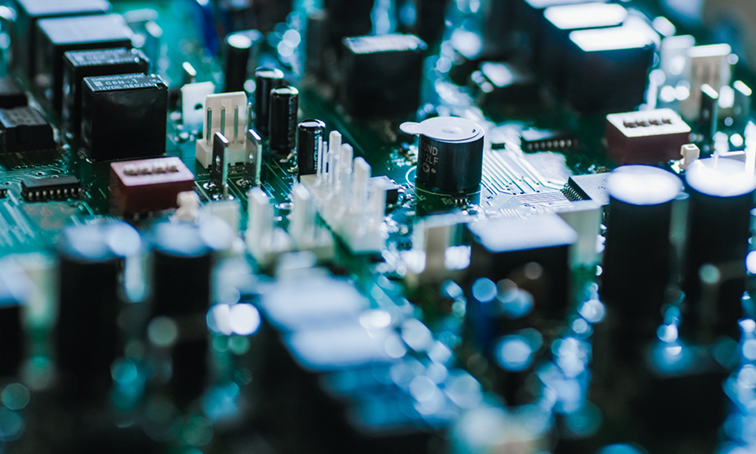

by Jimmy O. BloggerIn today's fast-paced technological landscape, printed circuit boards are the backbone of countless electronic devices, from smartphones to medical equipment. Behind the seamless functionality of these devices lies a complex process of design, manufacturing, and assembly facilitated by PCB services. This blog delves into the intricacies of PCB services, exploring their role in bringing innovative ideas to life.

PCB services encompass a wide range of specialized offerings to facilitate developing and producing printed circuit boards. These services cater to diverse needs, spanning design validation, prototyping, fabrication, assembly, and testing. Whether a small-scale project or a large-scale production run, PCB services provide the expertise and resources necessary to navigate each stage of the PCB lifecycle.

At

the heart of any PCB project lies the design phase, where engineers

conceptualize the layout and functionality of the circuit board. PCB

design services leverage sophisticated software tools to translate

these ideas into comprehensive schematics and layouts, ensuring

optimal performance and efficiency. Prototyping services are crucial

in validating designs, allowing engineers to test functionality and

identify potential issues before moving into full-scale production.

At

the heart of any PCB project lies the design phase, where engineers

conceptualize the layout and functionality of the circuit board. PCB

design services leverage sophisticated software tools to translate

these ideas into comprehensive schematics and layouts, ensuring

optimal performance and efficiency. Prototyping services are crucial

in validating designs, allowing engineers to test functionality and

identify potential issues before moving into full-scale production.

Fabrication and Manufacturing

The focus shifts to fabrication and manufacturing once the design is finalized and validated. PCB fabrication services utilize state-of-the-art equipment and processes to bring designs to fruition, from etching copper traces to drilling vias and applying solder masks. Advanced manufacturing techniques, such as surface mount technology and through-hole technology, ensure precision and reliability in the production process.

Assembled components are meticulously placed and soldered onto the PCB during assembly, requiring precision and attention to detail. PCB assembly services employ automated machinery and skilled technicians to ensure consistency and quality in the assembly process, PCB board manufacturer. Rigorous testing protocols, including functional testing and quality assurance checks, verify the integrity and performance of the finished PCBs before they are deployed in end products.

Customization and Flexibility

One of the critical advantages of PCB services is their ability to accommodate customization and flexibility to meet diverse project requirements. PCB service providers can tailor solutions to suit individual needs, whether it's a unique form factor, specialized materials, or specific performance criteria. From rapid prototyping services for fast-paced development cycles to high-volume production capabilities for mass deployment, PCB services offer scalability and versatility to address various applications.

Sponsor Ads

Created on Feb 12th 2024 03:24. Viewed 44 times.