Indium Tin Oxide as A Semiconductor Material

by Julissa G. Content generatorIntroduction:

In the vast realm of semiconductor materials, Indium Tin Oxide (ITO) stands as a luminary, casting its influence on various electronic devices. This article delves into the unique properties and applications of ITO as a semiconductor material, exploring its pivotal role in modern technology.

Understanding Indium Tin Oxide:

Indium Tin Oxide is a transparent, conductive oxide composed of indium, tin, and oxygen atoms. Its unique combination of transparency and conductivity makes it an invaluable material in the semiconductor industry. The typical composition consists of approximately 90% indium oxide (In2O3) and 10% tin oxide (SnO2).

Properties that Set ITO Apart:

Optical Transparency:

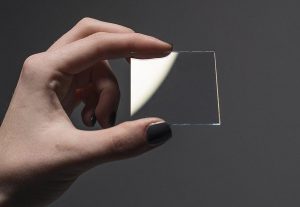

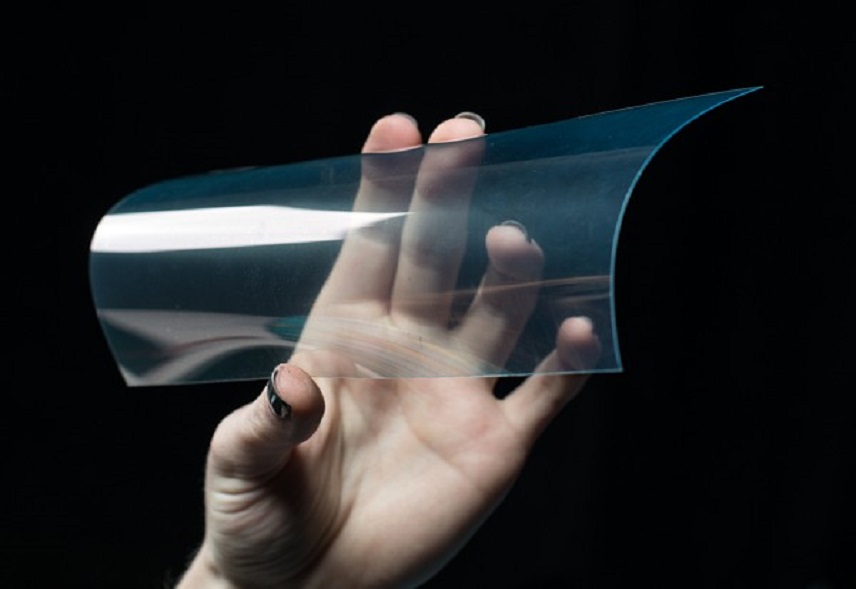

One of the distinctive features of ITO is its excellent optical transparency. This property allows light to pass through the material while maintaining electrical conductivity, making it ideal for applications requiring visible light transmission.

Conductivity:

ITO exhibits electrical conductivity, enabling the flow of electrical currents. This characteristic is crucial in the development of transparent conductive films used in various electronic devices.

Thin-Film Deposition:

ITO is often applied as a thin film on glass or other substrates using techniques like sputtering or chemical vapor deposition. This deposition method ensures uniformity and adherence, essential for its role in electronic components.

Applications of ITO in Semiconductor Devices:

Transparent Conductive Films:

The primary application of ITO lies in the creation of transparent conductive films. These films find use in electronic displays, touchscreens, and photovoltaic devices. The combination of transparency and conductivity makes ITO an ideal material for maintaining visibility while facilitating electronic functionalities.

Further Reading: Do you know what ITO film is? Click to check!

Liquid Crystal Displays (LCDs) and Organic Light-Emitting Diodes (OLEDs):

ITO-coated glass is a common feature in LCDs and OLEDs. In these displays, ITO serves as a transparent electrode, allowing for the precise control of pixels. The transparency of ITO ensures that the display remains visible while the electrical conductivity enables the functioning of individual pixels.

Solar Cells:

In solar cell technology, ITO is employed as a transparent conductive layer. This layer facilitates the efficient collection and transport of electrical charges generated by sunlight, contributing to the overall performance of solar panels.

Antistatic Coatings:

ITO's conductivity also finds applications in antistatic coatings for electronic devices and optical surfaces. By preventing the buildup of static electricity, ITO enhances the reliability and safety of sensitive electronic components.

Challenges and Future Developments:

While ITO has played a pivotal role in various technologies, there are challenges, including the scarcity and rising costs of indium. Researchers are exploring alternative materials and deposition techniques to address these concerns and advance the field of transparent conductive materials.

Conclusion:

Indium Tin Oxide, with its unique combination of transparency and conductivity, has become a cornerstone in semiconductor technology. From enhancing the visual appeal of displays to improving the efficiency of solar cells, ITO's influence permeates diverse electronic applications. As technology continues to evolve, the exploration of alternative materials and methods ensures that the semiconductor landscape remains brilliantly illuminated by innovations in materials like Indium Tin Oxide.

Sponsor Ads

Created on Dec 14th 2023 20:27. Viewed 59 times.

Comments

No comment, be the first to comment.