Best circulating pump for boiler cost

by Fangkuai Boiler boiler manufacturer

What is a circulating pump?

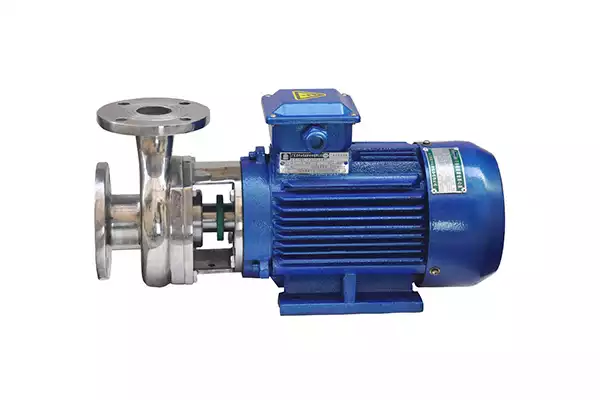

A circulating pump is a mechanical device that moves fluid by means of a rotating impeller. It is used to circulate fluids such as water, oil, or liquid fertilizer through closed piping systems.

There are three parts of a circulating pump: the casing, the motor and shaft assembly and the impeller.

The casing holds all the other parts together and protects them from damage. The motor and shaft assembly consists of two main components: an electric motor that powers the pump, and an attached shaft which transfers power from the electric motor to turn its impeller blades. The impeller does what you would expect; it circulates liquid through your pipes!

There are three types of circulating pumps: centrifugal pumps (or axial flow), turbine pumps (also called positive displacement), and mixed flow pumps. These can be further divided into subtypes based on their use or design specifics such as discharge direction (suction side vs discharge side).

How does a boiler circulating pump work?

A circulating pump is a type of electric motor that moves water through a system. A boiler-circulating pump, for example, uses an electric motor to circulate water through a boiler. This circulation allows the fuel used to heat the water in the boiler (oil or gas) to be used more effectively and efficiently by ensuring that all parts of the system receive adequate heat at all times.

When most people think about how a circulating pump works, they visualize an impeller (i.e., blades) rotating within an enclosed chamber (i.e., casing). But in reality, this isn't quite how it works! Instead:

The shaft turns the impeller - The shaft of your circulating pump will turn and rotate as you power on your unit; this rotates along with any other moving parts inside your unit's casing such as gears, bearings or seals (depending on what type of liquid is being pumped).

Is a circulating pump a centrifugal pump?

No, a circulating pump is not a centrifugal pump.

A circulating pump is a positive displacement pump and differs from a dynamic or centrifugal pump. A positive displacement pump includes the suction and discharge valves as part of the body of the pump. These valves are specially designed to provide minimal flow resistance when closed and maximum flow resistance when open, thus allowing both suction and discharge to occur at one time in each stroke cycle.

Dynamic pumps include no valves in their design; these types of pumps require an additional stroke element (or “piston”) that must be moved into position with each cycle in order to create suction or discharge conditions before moving on to its next position where it creates another cycle.

How long does a boiler circulator pump last?

A boiler circulator pump can last anywhere from a few months to several years. The life of a boiler circulator pump depends on the brand, model and type of pump you have. If you are using a good quality pump which is well maintained, it can last up to 5 - 10 years. However, if you have purchased a cheap quality one it may only last 1 - 2 year as they quickly break down due to poor construction.

Pumps that use a circulating system can be replaced before they break down, so there is no need to replace an entire heating system when your boiler circulator pump fails.

How do I know if my boiler circulator pump is bad?

If you're not sure whether or not your circulator pump needs to be replaced, there are a few ways to tell:

The pump won't turn on. If the pump doesn't come on when the heating system switches on or cycles through its heating process, then this could be a sign that something is wrong with the circulator pump or wiring. You may need to replace or repair one or both of these things in order for your boiler to function properly again.

The pump makes a loud noise. A loud screech or hum coming from the pump can mean that there's something stuck inside of it—like debris—and this needs to be removed before further damage occurs.

How much does a new circulator pump cost?

The cost of a new circulator pump depends on the brand, model and size. You can expect to spend between $200 and $800 for a new circulator pump, depending on what you want. The prices of the pumps vary according to their size and other features. Some pumps can be fitted with an automatic shutoff. The factors that affect price include whether it's an open-flow or closed-loop system, as well as if you want wireless connectivity enabled in your home automation system.

If you're looking for a new circulator pump at a lower price point, consider buying one secondhand from an online auction site like eBay or Craigslist. You may find an older model that's still in great condition and is less expensive than buying new!

Conclusion

Now you know how a circulating pump works and how much they cost to replace. If your boiler circulator pump is not working, don’t wait until it fails completely—call us today for service. We can help ensure that your replacement pump is installed correctly and will last for years without fail.

Sponsor Ads

Created on Oct 11th 2022 22:23. Viewed 36 times.