The Impact of Vacuum Brazing Welding Liquid Cold Plates on Sustainable Technology

Introduction: The Growing Demand for Sustainable Cooling Solutions

As the world increasingly focuses on sustainability and energy efficiency, the demand for environmentally-friendly technologies is higher than ever. Industries that rely on high-performance systems, such as electric vehicles (EVs), aerospace, telecommunications, and data centers, face the challenge of managing the heat generated by their powerful equipment. Cooling systems are essential to prevent overheating and ensure the optimal functioning of these systems. However, traditional cooling methods often require high amounts of energy and contribute to higher carbon footprints.

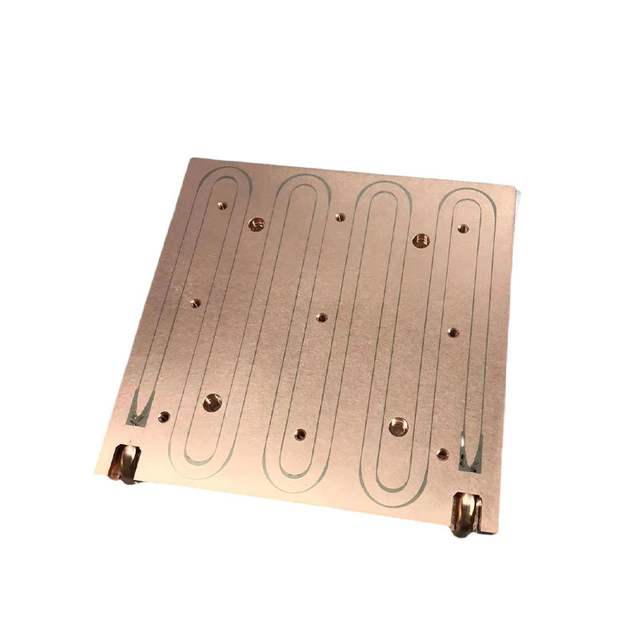

Vacuum brazing welding liquid cold plates offer a sustainable solution to this challenge. These high-performance cooling components provide efficient thermal management while reducing energy consumption and material waste. In this article, we will explore how these cold plates contribute to the development of sustainable technology in various industries.

What Makes Vacuum Brazing Welding Liquid Cold Plates Sustainable?

The sustainability of vacuum brazing welding liquid cold plates lies in their efficiency, durability, and minimal environmental impact. Here’s why they stand out as a sustainable choice for thermal management:

-

Energy Efficiency: Liquid cooling systems are generally more energy-efficient than air-based systems. By using coolant to transfer heat away from components, liquid cold plates require less energy to maintain optimal temperatures. This efficiency is particularly important in high-power systems, where energy consumption can be a significant concern.

-

Longevity and Durability: Vacuum brazing welding produces cold plates that are highly durable and resistant to wear, corrosion, and thermal stress. This long lifespan means fewer replacements and less waste, contributing to the sustainability of the overall system.

-

Material Efficiency: The vacuum brazing process allows for precise control over the material used in cold plate manufacturing. By using high-quality materials and minimizing waste during production, vacuum brazed cold plates reduce the overall environmental impact of manufacturing.

Applications of Sustainable Cold Plates Across Industries

-

Electric Vehicles (EVs): One of the most pressing sustainability challenges is reducing the environmental impact of transportation. Electric vehicles are a cleaner alternative to traditional gasoline-powered cars, but they still require efficient thermal management to ensure the safety and performance of their batteries. Vacuum brazing welding liquid cold plates help manage the heat generated by EV batteries, improving energy efficiency and extending battery life. This contributes to the overall sustainability of electric vehicles by reducing the need for energy-intensive cooling systems.

-

Aerospace: Aerospace applications require cooling solutions that are both reliable and efficient. The extreme conditions in which aerospace equipment operates make traditional air cooling systems less viable. Vacuum brazed liquid cold plates provide a more energy-efficient solution by improving heat dissipation without increasing energy consumption. This reduces the environmental impact of aerospace technologies while maintaining their high performance.

-

Telecommunications: With the rise of 5G networks and increased demand for data processing, telecommunications equipment needs to operate at high efficiency without overheating. Liquid cold plates provide a sustainable solution by maintaining the temperature of telecom equipment while consuming less energy than traditional cooling systems. This supports the continued expansion of telecommunications infrastructure while helping companies meet sustainability goals.

-

Data Centers: Data centers are major consumers of energy, with cooling systems often accounting for a significant portion of their energy usage. By using vacuum brazing welding liquid cold plates, data centers can reduce their cooling energy requirements, leading to lower operational costs and a reduced carbon footprint.

Economic and Environmental Impact

The sustainable nature of vacuum brazing welding liquid cold plates offers clear economic and environmental benefits:

-

Cost Reduction: By improving cooling efficiency and extending the lifespan of systems, vacuum brazing welding liquid cold plates help reduce operational costs. This includes both energy savings and the reduced need for frequent system replacements.

-

Lower Carbon Footprint: Efficient thermal management reduces the need for energy-intensive cooling systems, helping businesses lower their overall carbon emissions. This supports the growing demand for environmentally-conscious manufacturing and product development.

Comments