Maximizing Performance with Vacuum Brazing Welding Liquid Cold Plates in High-Power Systems

Introduction: The Role of Efficient Thermal Management in Modern Industries

In the world of modern technology, industries like automotive, aerospace, telecommunications, and electronics are pushing the boundaries of innovation. As devices and systems become more powerful, managing the heat they generate becomes a critical issue. Excessive heat can lead to reduced efficiency, premature failure, and safety concerns. Efficient thermal management is now at the core of designing and maintaining high-performance systems.

One of the most advanced solutions for managing heat in high-power systems is the vacuum brazing welding liquid cold plate. These components offer superior cooling performance, helping industries maintain optimal temperatures in high-demand environments. In this article, we’ll explore how vacuum brazing welding liquid cold plates are transforming industries and enabling the future of high-power systems.

What Are Vacuum Brazing Welding Liquid Cold Plates?

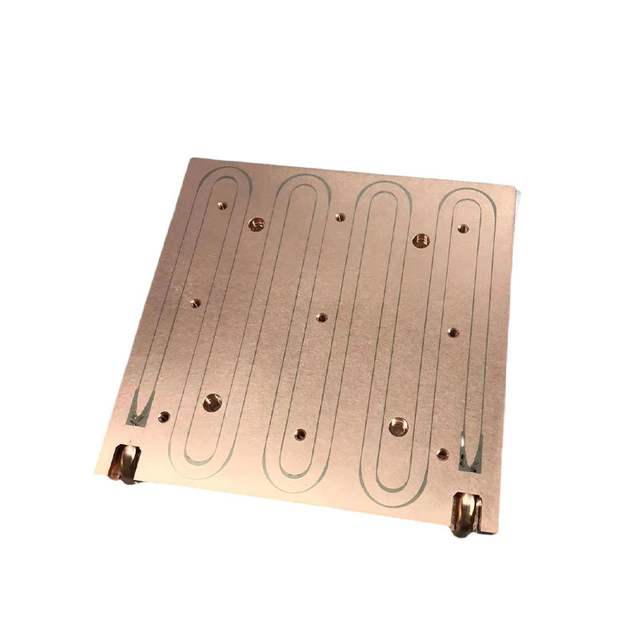

A liquid cold plate is a heat exchanger designed to absorb and remove heat from components such as processors, batteries, and power electronics. It works by circulating a cooling fluid through internal channels within the plate, which absorbs heat from the components and carries it away to prevent overheating.

The vacuum brazing welding process used in the production of liquid cold plates ensures they are strong, durable, and efficient. Unlike traditional brazing techniques, vacuum brazing occurs in a vacuum, eliminating contaminants and oxidation that could compromise the material's integrity. This results in cold plates with enhanced thermal conductivity, strength, and precision.

Why Vacuum Brazing Welding Cold Plates Are Ideal for High-Power Systems

In high-power systems, the ability to effectively dissipate heat is critical. Here’s why vacuum brazing welding liquid cold plates are the ideal solution for modern cooling needs:

-

High Thermal Conductivity: The clean, oxygen-free brazing environment ensures that the materials used in the cold plates have optimal heat transfer properties. This is crucial for systems that generate significant heat and need efficient cooling to maintain performance.

-

Durability and Reliability: The vacuum brazing process produces joints that are resistant to wear, corrosion, and thermal stress, making these cold plates highly reliable in demanding environments.

-

Precision and Customization: Vacuum brazing allows for precise manufacturing of cold plates, including the creation of intricate internal channels that maximize the heat exchange surface area. This level of precision ensures that the cold plates are tailored to meet the specific cooling requirements of different systems.

Applications in Key Industries

Vacuum brazing welding liquid cold plates are being adopted across various industries due to their superior performance and versatility:

-

Electric Vehicles (EVs): In EVs, battery packs and power electronics produce substantial heat. Liquid cold plates help maintain the optimal temperature of these components, ensuring efficient energy usage, improved battery life, and enhanced safety. These cooling solutions are essential in preventing battery overheating, which can lead to failure or even fires.

-

Aerospace: Aerospace applications require equipment that can operate reliably in extreme temperatures and harsh conditions. Vacuum brazing welding liquid cold plates are used to cool avionics, propulsion systems, and radar equipment. By maintaining the proper temperature, these cold plates ensure that aerospace systems perform at their best under challenging conditions.

-

Telecommunications: The rise of 5G technology has increased the demand for high-performance telecom equipment that can operate without overheating. Vacuum brazed liquid cold plates help maintain the temperature of telecom infrastructure, ensuring that equipment stays operational and efficient even during peak demand.

-

Data Centers: Data centers generate immense amounts of heat due to the large number of servers running continuously. Liquid cold plates are used to regulate the temperature of servers, preventing overheating and ensuring that the data processing power remains stable and uninterrupted.

-

Medical Devices: Many medical devices, such as MRI machines, CT scanners, and diagnostic tools, generate significant heat during operation. Vacuum brazing welding liquid cold plates ensure that these devices stay cool, allowing them to function reliably during long procedures.

Environmental and Economic Benefits

Beyond their technical advantages, vacuum brazing welding liquid cold plates also contribute to sustainability goals. Their superior thermal management reduces the need for additional cooling systems, resulting in lower energy consumption. This not only helps businesses reduce operational costs but also supports their environmental initiatives by minimizing their carbon footprint.

Additionally, the durability of these cold plates means they last longer, reducing the frequency of replacements and minimizing waste.

Conclusion: A Future-Ready Cooling Solution

As industries continue to evolve and require more powerful systems, efficient thermal management will be more critical than ever. Vacuum brazing welding liquid cold plates are at the forefront of this transformation, providing industries with an effective, durable, and energy-efficient solution for managing heat. By optimizing the performance of high-power systems, these cold plates ensure that electronics, machinery, and vehicles continue to operate at peak efficiency.

With further advancements in manufacturing techniques and materials, we can expect liquid cold plates to play an even larger role in shaping the future of thermal management.

Comments