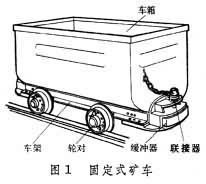

Mine Car Pusher for sale

There are three types of pusher car. They are the propellers, rope and hydraulic pusher. SBE car machine widely used in mining and quarry mining process species, such as limestone mining, mining granite, quartz ore, marble ore, coal, bauxite, feldspar, copper, and the like.

pusher car is mainly used for coal mine or wellhead shaft bottom dispatch tub, flatbed, materials, vehicles and other transport vehicles and auxiliary materials. It can be used for metallurgical and mining yards, parking lots and nonmetal mines, and engineering and construction yard (such as a tunnel) transport scheduling transportation yard work. It has high production efficiency, simple operation, easy to use, safe and reliable.

pusher car is mainly used for coal mine or wellhead shaft bottom dispatch tub, flatbed, materials, vehicles and other transport vehicles and auxiliary materials. It can be used for metallurgical and mining yards, parking lots and nonmetal mines, and engineering and construction yard (such as a tunnel) transport scheduling transportation yard work. It has high production efficiency, simple operation, easy to use, safe and reliable.

Pusher working conditions

1) Ambient temperature: -10 ℃ ~ 40 ℃

2) Relative humidity: ≤90%

3) Altitude: ≤2000 m

4) atmospheric pressure: 80-120KPa

5) prohibits the use of methane and other explosive gas mixtures excessive bottomhole

6) hydraulic and electrical parts should use the premises in a waterproof, placed inclination should be less than 5 degrees

1. Two car system in the curved portion of the track, and drive along the curved track sections spaced longitudinal movement of the guide includes a curved section of track between the rails arranged side by side, and each group is relatively staggered along the curved track area the driver stage, and for driving the two mutually opposite directions, my car is engaged in alternating and continuous two drivers.

2. Push carts subsystem to claim 1, wherein the group including drivers car drivers are connected to one end of the curved track sections connected to the driving means.

3. Extending tub push the claim 2 wherein the system is arranged in two groups of curved track sections away from the drive way to end the two carriage drivers car tension member diverting pulley mounted in a fixed position of the connection request.

4. Push carts subsystem in claim 3, wherein the drive device tension element through an arc around the track sections adjacent to the final round, said tension element connecting two car car, next to the driver.

1) Ambient temperature: -10 ℃ ~ 40 ℃

2) Relative humidity: ≤90%

3) Altitude: ≤2000 m

4) atmospheric pressure: 80-120KPa

5) prohibits the use of methane and other explosive gas mixtures excessive bottomhole

6) hydraulic and electrical parts should use the premises in a waterproof, placed inclination should be less than 5 degrees

1. Two car system in the curved portion of the track, and drive along the curved track sections spaced longitudinal movement of the guide includes a curved section of track between the rails arranged side by side, and each group is relatively staggered along the curved track area the driver stage, and for driving the two mutually opposite directions, my car is engaged in alternating and continuous two drivers.

2. Push carts subsystem to claim 1, wherein the group including drivers car drivers are connected to one end of the curved track sections connected to the driving means.

3. Extending tub push the claim 2 wherein the system is arranged in two groups of curved track sections away from the drive way to end the two carriage drivers car tension member diverting pulley mounted in a fixed position of the connection request.

4. Push carts subsystem in claim 3, wherein the drive device tension element through an arc around the track sections adjacent to the final round, said tension element connecting two car car, next to the driver.

Advertise on APSense

This advertising space is available.

Post Your Ad Here

Post Your Ad Here

Comments