Concrete Crushing Plant sale in Brunei

We need to do is to waste in raw concrete.

Recycled concrete refers to concrete blocks abandoned after crushing, cleaning, grading, and graded by a certain percentage mixed, replace some or all other natural gravel aggregate (mainly coarse aggregate), then add cement and water distribution from the new concrete. Press the combination of recycled concrete aggregate can have the following situations: Aggregate all renewable aggregates; coarse aggregate regenerative aggregate, fine aggregate was natural sand; coarse aggregate natural gravel or pebbles, fine materials for the Recycled aggregate; Recycled aggregate replace part of the coarse aggregate or fine aggregate.

Treatment

1. Pretreatment: hydraulic hammer big stone pressed into a smaller one, and arrange for the workers through long tendons cut to prevent damage to the belt conveyor.

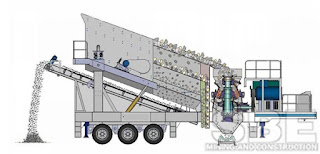

2. Crushing process: pre-treated material will be sent to the jaw crusher, and set the exhaust valve 100mm, using an impact crusher and discharge doors in 50mm material recovery process secondary crusher Actual show, jaw crusher can be easily treated steel raw. materials, and can be cut and separated from the bar. At the same time, fine crushing feeling is very good. Finally, the size of 0-5mm jaw crusher, impact crusher use a screen, 5-50mm. Customer stability crushing process was highly evaluated. The actual photo production line, construction waste and steel, the magnet separator and scrap iron rods stack as shown in Figure 2.

More information can be found at:

Post Your Ad Here

Comments