Calcium Carbonate Mill price in Valencia

Calcium carbonate is an inorganic material, with non-poisonous, odorless, tasteless,which is a very environmentally friendly material, through scientific and technological innovation, and expand the use of calcium carbonate, calcium carbonate is used for increasing the amount of energy saving is important.

Plastic, for example, the current total output of plastic products and materials amounted to 70 million tons / year, while the plastic processing the largest amount of filler is calcium carbonate powder, calcium carbonate filler for plastics per year is about 900-1000 tons. In short, the calcium carbonate industry is a sunrise industry, development is very big.

Calcium Carbonate Mill price in Valencia

Processing

Calcium carbonate, calcium carbonate milling is generally divided into a coarse powder processing (0-3MM), powder processing (20 mesh -400 mesh), and deep processing of calcium carbonate superfine powder (400 mesh -1250) and powder processing (1250 head -3250 mesh) four types.

The first stage: Shattered

Calcium carbonate bulk materials through the crusher to be able to enter the mill feed fineness (15 mm -50mm) of.

Phase II: flour

Crushed calcium carbonate material through the small elevator to the hopper, and then by the vibrating feeder evenly into the mill to quantitative interior polished.

Powder processing generally used LM vertical roller mill, MTW European version of the mill, TGM Super Pressure Trapezium Mill;

Superfine powder processing is generally used LUM Ultrafine vertical mill, HGM medium-speed micro-grinding.

Phase III: Classification

Material through the separator after grinding grading, unqualified powder will be returned to the host after the election, re-grading machine grinding the powder.

Phase IV: powder collector

Powder will meet the fineness with the air through the pipe into the dust collector separated collection, finished powder collected through the discharge port by the conveying means to the storage bin, and then unified with the powder tanker loaded automatic balers or packaging.

Calcium Carbonate Mill

1. EfficientCompared jet mill, stirred mill and the same finished size and motor power mill, HGM powder mill has a dual capacity, and save 30% energy.3. High fineness and flexibility adjustmentThe product size can be adjusted between 325 mesh to 2500 mesh (47-5micron).

2. Alternate special materials PartsForged long life ring and roller mill calcium carbonate.4 can use about a year. Environmental pulse dust collector and muffler applications friendlyThe greatly reduce dust pollution and noise.

Ultrafine rotor type powder separator

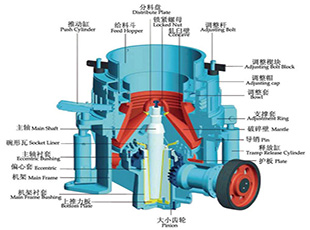

Drive spindle motor and the reducer through each turntable. Many drive gear wheel against rotation by pin-lap race mode. By hammer crusher small material delivered to the hopper by the elevator, and then vibrating feeder shall be evenly fed into the upper portion of the central portion of the turntable. This material falls on the circle under the centrifugal force and comes down to the ring raceways are crushed into a powder. Ground in the first game after the way the material into the second and third turntable. Outside air into the blower and the third rotary mill into powder powder separated. Turbine in the separator makes the coarse powder drop down and regrinded and fines should the air flow into the cyclone powder collector together and go through the discharge valve as final product; at the same time, with a little dust airflow through blower and muffler from the filtered and purified off

More information can be found at:

Post Your Ad Here

Comments