Fixed Inductors: A Comprehensive Guide You Must Read | ICE Components, Inc.

Even the smallest parts of an electronic circuit are important in a world of continually changing technology. The fixed inductor is one of the most important but undervalued parts. Numerous devices rely on these quiet workhorses for

reliable energy storage,

smooth operation, and

efficient signal filtering.

Everything you need to know about fixed inductors is covered in this news release, including how they work, why they are important. You can also learn when high current or bespoke inductors are a better option.

What is a Fixed Inductor and Why Should You Care?

When electric current passes through a fixed inductor, a passive electrical component, energy is stored in a magnetic field. The main characteristic that sets it apart? In contrast to variable inductors, which may be adjusted, its inductance value stays constant.

However, why is that significant?

Because dependability, stability, and reproducibility are crucial in the exciting design contexts of today. For delicate applications like power supply, radio frequency circuits, and communication devices, a fixed inductor's reliable performance is essential.

The Role of Fixed Inductors in Modern Electronics

Much of the power, speed, and tiny size of today's electronics can be attributed to fixed inductors. Usually, you may locate them here:

1. Power Supply Regulation

In switching power supply and DC-DC converters, fixed inductors are essential components. They help control power distribution to

downstream components,

smooth out noise, and

smooth out voltage.

2. Signal Filtering

In order to maintain clear and effective data transmission, fixed inductors minimize undesired high-frequency interference. It is regardless of whether you're working with analog or digital information.

3. RF and Communication Systems

Fixed inductors are essential components of tuning circuits, frequency selection, and impedance matching in radio transmitters and receivers.

Compact surface-mount versions of these adaptable components, such as the high-performance SMT high current inductor, are now available. These versions are designed for today's power-consuming, tiny electronics.

Fixed Inductor and Fixed Inductors: More Than Just a Name

The phrases "fixed inductor" and "fixed inductors" are frequently used interchangeably. While the plural frequently covers categories or many components, the singular refers to a specific unit.

In any case, they both highlight the solidity and dependability that this part offers. Fixed inductors range from a single coil in a simple circuit to hundreds on a sophisticated PCB. They guarantee reliable performance without the unpredictability associated with adjustable choices.

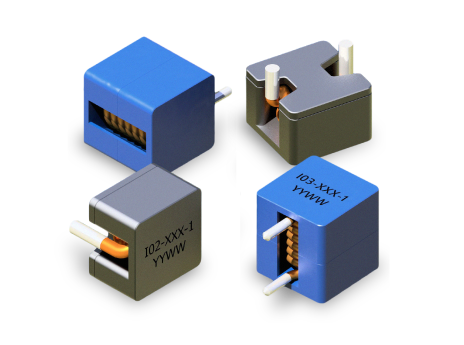

Key Types of Fixed Inductors

Engineers can choose the ideal fixed inductor for their application by being aware of the several types available:

Air Core Fixed Inductors:With no core saturation, it is perfect for high-frequency applications.

Iron Core Fixed Inductors: Excellent for applications requiring a higher inductance at low frequencies.

Ferrite Core Fixed Inductors: Often used in high current inductors, these devices have superior efficiency and magnetic permeability.

These days, a lot of them come in SMT high current inductor configurations, which makes them perfect for high-density, small circuit boards.

Fixed Inductors vs Custom Inductors: Which Do You Need?

Certain applications require specialized requirements, even though fixed inductors are available in a range of common values and formats. Custom inductors can help with it.

When to Choose Custom Inductors:

When size constraints limit standard component use.

When the design calls for non-standard inductance values.

When harsh environmental conditions demand special materials or coatings.

It is possible to construct custom inductors to precisely match specifications, providing flexibility without compromising performance.

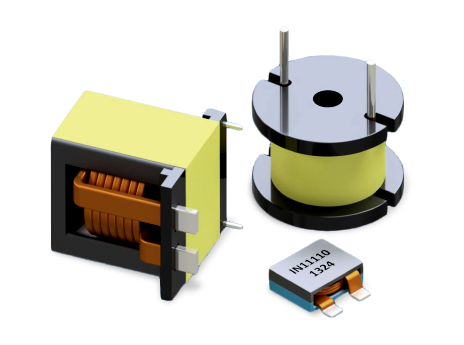

The Power of High Current Inductors

Power-hungry applications of today require load-bearing components. In order to handle high current flows without saturation or energy loss, high current inductors are made with

thicker wire gauges,

sophisticated core materials, and

improved heat dissipation capabilities.

Common Use Cases:

Electric Vehicle Powertrains

Industrial Motor Drives

Solar Inverters and Power Optimizers

High-Performance Computing

For easy incorporation into contemporary designs, numerous manufacturers now provide high current inductors in both through-hole and SMT high current inductor formats.

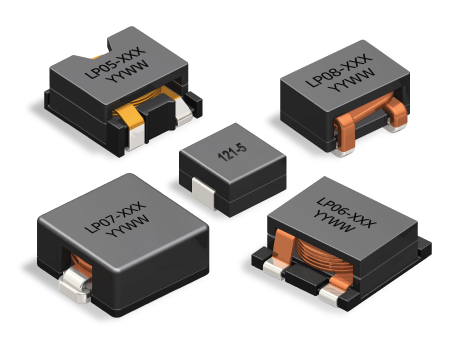

Why SMT High Current Inductors Are in High Demand

Modern circuit boards have limited space. Presenting the SMT high current inductor, a small, surface-mount device that provides a high current capacity without taking up more board space.

Advantages Include:

Easy compatibility with automated assembly lines

Lower profile for slim electronic devices

High thermal performance

Excellent EMI suppression

SMT high current inductors provide unparalleled efficiency in confined locations. It doesn’t matter whether you're developing for

robotics,

electric vehicles,

the Internet of Things, or

industrial controls.

Selecting the Right Fixed Inductor for Your Design

The inductance value is not the only consideration when selecting a fixed inductor. Engineers ought to think about:

Inductance Rating: Typically measured in microhenries (µH) or millihenries (mH).

Current Rating: Maximum current the inductor can handle without saturation.

DC Resistance (DCR): Lower resistance equates to higher efficiency.

Core Material: Impacts frequency performance and size.

Mounting Style: Through-hole vs. surface mount, depending on your board design.

Naturally, you should also consider if you require a more customized custom inductor or a regular off-the-shelf option.

Concluding Words

The fixed inductor continues to be one of the most important yet underappreciated components in contemporary electronics. It could range from consumer electronics to sturdy industrial machinery. Without it, the following elements could would lose their dependability, these include:

circuits would malfunction,

signals would skew, and

gadgets.

Selecting the appropriate fixed inductors, or going with custom or high current inductors. It is regarded as the key to achieving the best possible performance and product success. It is irrespective of the situation whether you're developing a mobile phone, smart home system, or electric car control unit.

Additionally, engineers may now use small, strong components that fit even the most space-constrained designs. It is all possible because of sophisticated solutions like the SMT high current inductor.

The permanent inductor is the quiet engine that powers our electronic-powered world; it has the following quality and is mostly opted for the nature that includes:

reliable,

robust, and

vital.

Post Your Ad Here

Comments