The Functionality of Stainless Steel Valve in High-Performance Systems

In industrial systems with high performance, the selection of valves is important to guaranteeing efficiency, reliability, and lifespan. Stainless steel valves are essential in industries such as oil and gas, chemical processing, power generation, and water treatment. Their corrosion resistance, strength, and endurance at high temperatures make them the go-to option for demanding applications. If you wish to find a reliable stainless steel valve manufacturer in India, learning about their working and advantages is a must.

Why Stainless Steel Valves Are Ideal for High-Performance Systems

1. Corrosion Resistance

One of the primary advantages of stainless steel valves is their resistance to corrosion. Unlike conventional materials, stainless steel does not degrade when exposed to harsh chemicals, high humidity, or saline environments. This makes it particularly beneficial for industries such as marine, pharmaceuticals, and food processing, where hygiene and longevity are paramount.

Case Study: Marine Industry Application

A leading shipping company faced frequent valve replacements due to corrosion in its seawater pipelines. After switching to stainless steel valves, the company reported a 60% reduction in maintenance costs and increased operational efficiency, demonstrating the material’s resilience in harsh environments.

2. High Temperature and Pressure Tolerance

High-performance systems often operate under extreme temperature and pressure conditions. Stainless steel valves can withstand high-pressure environments without deforming or failing. Their ability to maintain structural integrity even in extreme heat or sub zero conditions ensures operational efficiency and safety.

Expert Insight:

According to Rajesh Patel, a senior mechanical engineer at a power plant, “We transitioned to stainless steel valves in our high-temperature steam lines five years ago, and they have outperformed every alternative we tried. Their ability to handle rapid temperature changes without degradation is unparalleled.”

3. Strength and Durability

The strength of stainless steel enhances the durability of valves, reducing maintenance and replacement costs. This is particularly advantageous in industrial applications where downtime due to equipment failure can lead to significant financial losses.

Real-World Example: Oil Refinery Efficiency

An oil refinery in Gujarat replaced its aging cast-iron valves with stainless steel alternatives. As a result, the plant saw a 30% increase in operational uptime and a drastic reduction in unexpected breakdowns, reinforcing the long-term value of stainless steel components.

4. Minimal Contamination Risk

For industries like pharmaceuticals and food processing, contamination must be minimized. Stainless steel is non-porous and does not react with chemicals, preventing leaching and ensuring product purity. This property makes it an excellent choice for handling sensitive materials.

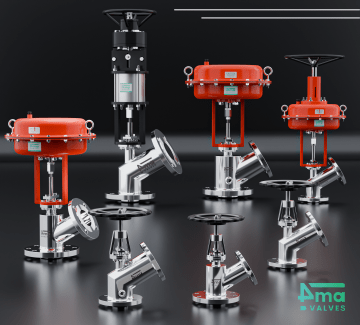

Types of Stainless Steel Valves for Industrial Applications

1. Ball Valves

Ball valves provide tight shutoff capabilities and are ideal for controlling high-pressure and high-temperature fluids. Their quick operation and minimal maintenance make them a preferred choice in oil and gas industries.

2. Gate Valves

Gate valves are used in applications requiring full flow with minimal resistance. These valves are commonly used in water distribution, power plants, and wastewater treatment facilities.

3. Globe Valves

Globe valves offer precise flow control and are widely used in steam applications, power plants, and chemical industries. Their ability to regulate pressure makes them suitable for throttling operations.

4. Check Valves

Check valves ensure a controlled one-way flow, automatically blocking any reverse movement to protect system integrity and efficiency. These are essential in industries such as petrochemical, oil refining, and water treatment plants.

5. Butterfly Valves

Butterfly valves are lightweight and cost-effective, making them ideal for large-scale applications requiring quick shutoff and flow regulation.

Applications of Stainless Steel Valves in Various Industries

1. Oil and Gas Industry

Stainless steel valves are widely used in oil refineries and gas processing plants due to their ability to handle high pressure and resist corrosive elements.

2. Chemical Processing

In chemical industries, where exposure to acidic and caustic substances is frequent, stainless steel valves offer superior resistance and reliability.

3. Water Treatment Plants

Water treatment systems require valves that prevent contamination and withstand constant exposure to varying pH levels. Stainless steel is an ideal material due to its non-reactive properties.

4. Power Generation

From nuclear to thermal power plants, stainless steel valves play a crucial role in controlling steam and coolant flow, ensuring safe and efficient energy production.

5. Pharmaceutical and Food Industries

Strict hygiene standards in the pharmaceutical and food sectors necessitate the use of stainless steel valves, which prevent contamination and maintain product integrity.

Choosing the Right Stainless Steel Valve Manufacturer in India

When selecting a stainless steel valve manufacturer in India, consider the following factors:

1. Quality Certifications

Ensure that the manufacturer complies with international quality standards such as ISO, API, and ASTM.

2. Material Grade Selection

Different applications require different stainless steel grades, such as 304, 316, and 316L. A reliable manufacturer will guide you in choosing the right material for your needs.

3. Customization and Technical Support

Look for manufacturers that offer customized solutions, technical assistance, and after-sales support to ensure long-term performance.

4. Industry Expertise

Experience in catering to diverse industries indicates the manufacturer’s ability to deliver reliable and industry-specific solutions.

Conclusion

Stainless steel valves are indispensable components in high-performance systems, offering unmatched durability, corrosion resistance, and operational efficiency. Whether used in oil refineries, water treatment plants, or pharmaceutical industries, these valves ensure smooth and safe operations. Choosing a reputable stainless steel valve manufacturer in India ensures that you get high-quality, reliable products that enhance the efficiency of your industrial applications.

For businesses looking to invest in top-grade stainless steel valves, partnering with an experienced manufacturer is key to achieving long-term success and operational excellence.

Post Your Ad Here