Assembled Liquid Cold Plates: A Practical Cooling Solution for High-Power Industrial Applications

As industries continue to adopt higher power densities and more compact system designs, thermal management has become a limiting factor in performance, reliability, and lifecycle cost. For many B2B applications, especially in power electronics and advanced equipment manufacturing, assembled liquid cold plates are emerging as a highly practical and cost-effective cooling solution.

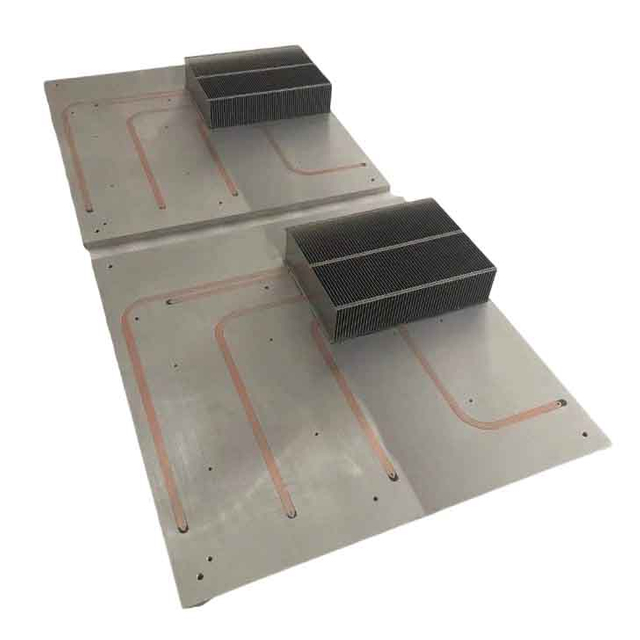

Rather than relying on a single-piece structure, assembled liquid cold plates are built from multiple precision-machined components that are joined into a sealed cooling unit. This construction approach allows engineers and procurement teams to balance thermal performance, manufacturability, and customization—three priorities that often conflict in traditional cooling designs.

Addressing Real-World Heat Challenges in Industrial Systems

In industrial environments, heat generation is rarely uniform. Power modules, control boards, and electronic components often produce localized hot spots that cannot be managed efficiently with air cooling or standard heat sinks.

Assembled liquid cold plates are specifically well-suited to these scenarios. Their internal flow channels can be engineered to deliver coolant precisely where heat density is highest, improving temperature consistency across the system. This targeted cooling approach reduces thermal stress on components and helps maintain stable operation under continuous or peak loads.

A Strong Fit for B2B Manufacturing and OEM Projects

From a business perspective, assembled liquid cold plates align well with how OEM and contract manufacturing projects are structured. Their layered design supports:

-

Design customization without excessive tooling investment

-

Easier iteration during prototype and validation phases

-

Scalability from low-volume production to larger batch manufacturing

For companies developing new equipment or upgrading existing platforms, this flexibility shortens development cycles while keeping long-term production costs under control.

Manufacturing Efficiency and Quality Control

Another advantage of assembled liquid cold plates lies in manufacturing efficiency. Different functional layers can be optimized independently during machining, allowing tighter tolerances where needed and cost savings where possible.

This approach also improves quality control. Critical surfaces, sealing areas, and flow structures can be inspected before final assembly, reducing the risk of hidden defects. Once assembled, cold plates can be pressure-tested to ensure leak resistance—an essential requirement for industrial cooling systems.

Long-Term Reliability as a Business Consideration

For B2B buyers, cooling solutions are not just technical components; they are long-term investments. Downtime caused by thermal failure can result in lost productivity, warranty claims, or reputational damage.

Properly engineered assembled liquid cold plates are designed to operate reliably over extended periods, even in demanding environments involving vibration, pressure variation, and thermal cycling. This reliability translates directly into lower maintenance costs and improved system uptime.

Common Application Scenarios

Assembled liquid cold plates are increasingly used in:

-

Power supply and inverter systems

-

Industrial automation equipment

-

Energy storage and battery systems

-

High-performance computing and control hardware

In each case, the need for compact design, efficient heat transfer, and dependable operation makes liquid cooling—and assembled cold plates in particular—a logical choice.

Conclusion

As industrial systems become more powerful and compact, thermal management can no longer be treated as an afterthought. Assembled liquid cold plates offer a balanced solution that meets both engineering and business requirements, combining performance, flexibility, and manufacturability.

For OEMs, system integrators, and industrial equipment manufacturers, adopting assembled liquid cold plates is not just about improving cooling—it is about enabling more reliable products, faster development cycles, and sustainable long-term operation.

Comments