How Soldering Improves Heat Sink Production for Industrial Applications

In industrial electronics, performance and reliability are critical, but production efficiency is equally important. For manufacturers designing and delivering thermal solutions at scale, soldering-based heat sink assembly offers a unique combination of high thermal performance and manufacturing practicality.

Understanding the advantages of soldering can help companies optimize both product quality and production workflow.

Optimizing Thermal Performance

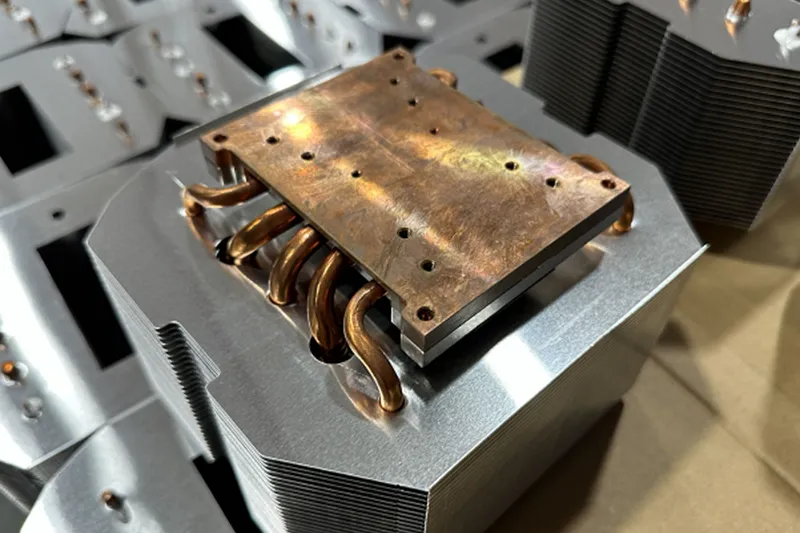

Soldered heat sinks create a continuous metallic bond between fins and base plates, which reduces thermal resistance. This ensures that heat is effectively transferred away from high-power components, even in compact or complex assemblies. The result is more predictable thermal performance, which is crucial in industrial settings where failure is not an option.

Flexible Design for Custom Applications

Industrial systems often have non-standard form factors or localized heat sources. Soldering allows fins, plates, and spreaders to be joined modularly, making it easier to design heat sinks tailored to specific applications. This flexibility supports rapid prototyping and custom production without sacrificing thermal efficiency.

Improving Production Consistency

Soldering processes are highly controllable. Variables such as solder amount, heating profile, and fixturing can be standardized, reducing variability between units. This predictability is particularly valuable for medium-volume production runs where maintaining consistent quality is essential.

Cost-Effective for Low-to-Medium Volumes

Compared to fully machined or exotic cooling solutions, soldered heat sinks offer a more cost-efficient route for customized industrial products. Initial setup is manageable, and the process scales well without excessive capital investment, balancing cost and performance effectively.

Supporting Long-Term Reliability

Soldered joints provide structural integrity under thermal cycling and mechanical stress, which is common in industrial equipment. Heat sinks maintain contact and performance over time, reducing maintenance needs and downtime, which are major considerations in industrial operations.

The Industrial Advantage

For companies supplying industrial electronics, soldering-based heat sinks represent a practical approach that combines thermal efficiency, production consistency, and scalability. By integrating this method into their workflow, manufacturers can deliver reliable products while managing cost and production complexity.

Comments