What is Active Packaging?

Food packaging's conventional function is evolving in response to shifting market demands. Consumer demand for safer, "healthier," and higher-quality foods, ideally with a long shelf life; demand for simple and visible packaging; and preference for more sustainable packaging materials have all contributed to the development of novel packaging technologies, such as Active Packaging (AP).

AP systems are designed to "deliberately contain components that would leak or absorb substances into or from the packed food or the environment surrounding the food. As a result, AP materials are "designed to increase the shelf-life of packaged food or to preserve or improve its condition." Despite substantial study into AP technologies, several of these technologies have yet to be successfully applied in commercial food packaging systems.

The effective development and commercial introduction will be aided by widespread communication of their benefits in food product applications. An overview of Active Packaging technologies, such as antimicrobial, antioxidant, or carbon dioxide-releasing systems, as well as systems that absorb oxygen, moisture, or ethylene, is provided in this review, with a focus on scientific publications that demonstrate the benefits of such technologies for specific food products.

Examples of AP

• Corrosion

Items can be treated with corrosion inhibitors to help prevent rust and corrosion. Vapor phase corrosion inhibitors can be put into a saturated overwrap of special paper or plastic film or delivered inside a package in a pouch. Many of them are organic salts that condense on metal in order to protect it from corrosion. Some films also have the ability to emit VCI. It is a good type of Moisture Absorber.

VCIs come in a variety of forms, including papers, plastics, HDPE papers, oils, foams, chips, aluminum barrier foils, bubbles, and emitters, all of which can prevent corrosion at various stages.

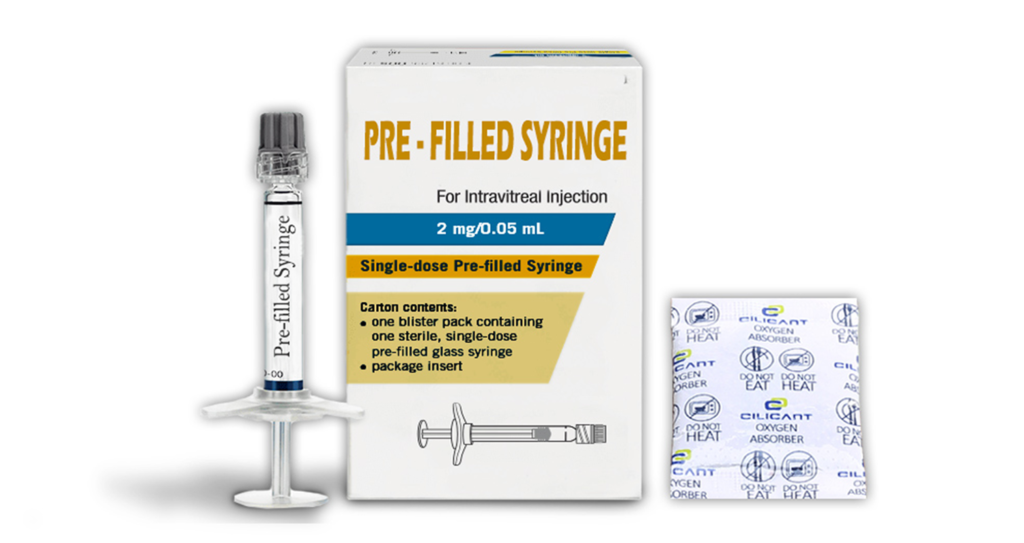

• Control of oxygen

Oxygen scavengers or oxygen absorbers assist in the removal of oxygen from a sealed container. Some are little packets or sachets containing powdered iron, which removes oxygen from the surrounding atmosphere as the iron rusts. Newer systems can be integrated into package films or molded structures, or they can be on cards. Furthermore, the physical properties of the packing (oxygen transmission rate - OTR) might influence how efficient an oxygen absorber is and how long it lasts. Packaging with a low OTR allows less oxygen to pass through the polymer barrier into the sealed product.

Conclusion

A good Moisture Absorber will not only increase the shelf life of your products, but they will also play a big role in maintaining their quality.

Advertise on APSense

This advertising space is available.

Post Your Ad Here

Post Your Ad Here

Comments