What Engineering Projects Can Gain from FEA Analysis Services?

Ensuring that a product or structure's design can withstand stresses and circumstances experienced in the real world is an important issue in the domains of engineering and product development. Finite Element Analysis (FEA), a powerful simulation technique, allows engineers and designers to evaluate the performance and behaviour of their creations before they are ever manufactured. Let’s reflect on the significance of FEA analysis services offered in Brisbane or anywhere else will be highlighted, along with how they enhance the efficacy, dependability, and overall success of engineering projects.

A Better Iteration Of The Design:

Engineers may virtually iterate through several design configurations thanks to FEA analysis services in Brisbane and anywhere else, saving time and money by skipping the need for physical prototypes for every design modification. The process of product development is greatly accelerated by this.

Weight Loss And Optimisation:

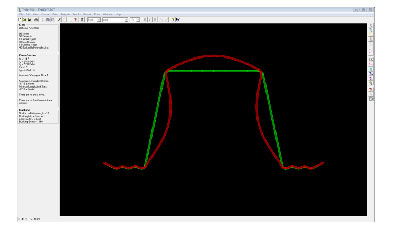

Engineers can identify design flaws and concentrated areas of high stress using FEA analysis. This helps to prevent catastrophic failures in real-world applications by making buildings safer and more reliable. The behaviour of the structure under the conditions it would encounter in the actual world can be predicted by FEA analysis. Before the structure is erected, engineers can find possible weak points and areas of high stress by testing the structure in a virtual environment. This enables them to alter the design before construction to make the building more dependable and safer.

Increasing Safety and Reliability:

Using FEA analysis, engineers can find design defects and concentrated areas of high stress. Making structures safer and more trustworthy, helps to avoid catastrophic failures in real-world applications.

Cost-Efficiency:

By decreasing the requirement for physical testing and the number of design iterations required to produce an optimised and validated design, using FEA analysis services can result in significant cost savings. FEA analysis can also be used to enhance the performance and dependability of already-existing items as well as to spot potential flaws before a product is released. This promotes the safety and excellence of the product.

Product Performance Forecast:

Using FEA, engineers may forecast how their designs will function under various loads, temperatures, or fluid flows. This information is necessary to guarantee that the product works efficiently and lasts a long time in practical situations. FEA can also be used to pinpoint design flaws and enhance designs for better performance. Products made as a result may be lighter, more effective, and more affordable.

The usage of Finite Element Analytical (FEA) analytical services has altered the way engineers in Brisbane and anywhere else approach structural design and product development. When engineers use FEA to visually mimic the behaviour of complex systems, they can uncover potential design flaws, enhance performance, increase safety, and save costs. It has grown into an important instrument that not only expedites the design process but also plays a crucial role in the development of innovative and dependable technical solutions for a range of industries. As technology advances, FEA analysis services will probably remain a crucial element in the pursuit of efficient and dependable engineering projects.

Engineering success is mostly dependent on FEA analysis services. Improve designs, guarantee safety, cut costs, and quicken product development.

Advertise on APSense

This advertising space is available.

Post Your Ad Here

Post Your Ad Here

Comments