The Glue that Powers Innovation: Electronic Adhesives Unveiled

In the world of electronics, innovation often hinges on the tiniest of

details. While we marvel at the sleek designs and impressive functionalities of

our electronic devices, we often overlook the unsung heroes that enable this

progress—electronic adhesives. Within this realm, three key players have been

making waves: Deep Material Underfill Epoxy, PCB Potting

Compound, and Conformal Coatings for Electronics. These adhesives form the

backbone of modern electronics, driving innovation, and pushing the boundaries

of what is possible.

Deep Material Underfill Epoxy: Unlocking the Potential of

Microelectronics

Deep Material Underfill Epoxy is a secret weapon in the arsenal of

microelectronics, allowing manufacturers to push the limits of miniaturization.

This advanced adhesive is designed to fill the gaps, secure components, and

protect against environmental factors, ensuring that even the tiniest of

devices can function reliably.

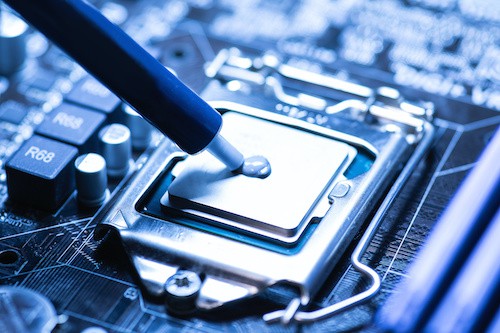

One of the most exciting applications of Deep Material Underfill Epoxy is in

the world of semiconductor manufacturing. As electronic components continue to

shrink, there is an increasing demand for reliable bonding agents to secure

these components to printed circuit boards (PCBs). Deep Material Underfill

Epoxy steps in to fulfill this need, ensuring that semiconductor chips can be

securely bonded to PCBs.

Take, for example, the ubiquitous smartphone. Inside these slim, powerful

devices are semiconductor chips responsible for processing data and running

applications. To accommodate these chips, they must be securely attached to the

PCB. Deep

Material Underfill Epoxy fills the gaps between the chip and the PCB,

preventing the formation of air pockets that could lead to stress and

mechanical failure. The result is a compact, high-performance device that not

only functions smoothly but also boasts impressive durability.

The automotive industry also benefits greatly from Deep Material Underfill

Epoxy. Advanced driver-assistance systems (ADAS) and in-vehicle infotainment

systems rely on compact, robust electronic components. These systems are

exposed to temperature variations and mechanical stress on the road. Deep

Material Underfill Epoxy ensures the durability of these components, allowing

automakers to create innovative, reliable solutions for their customers.

PCB Potting Compound: Protecting the Heart of Electronics

Printed Circuit Board (PCB) potting compound is another adhesive technology

that has undergone remarkable advancements. Potting compound is used to

encapsulate and safeguard PCBs, ensuring their longevity and reliability. As

the demand for smaller, smarter electronics continues to grow, PCB potting

compound plays a crucial role in preserving the core of electronic devices.

With miniaturization comes the challenge of denser PCBs with delicate

components. These components are vulnerable to physical damage, moisture, and

other environmental factors. PCB potting compound addresses these concerns by

providing a protective shell around the PCB, effectively sealing it from

external elements.

The aerospace industry is one notable sector where PCB potting compound

plays a pivotal role. Aerospace electronics are exposed to extreme conditions,

including temperature fluctuations, pressure changes, and vibrations. The

potting compound not only shields the components but also enhances their

resistance to mechanical stress, thermal cycling, and other factors that could

compromise their performance. This technology contributes significantly to the

reliability of critical systems in the aerospace field.

Similarly, the automotive industry benefits from PCB potting compound,

especially in the development of electric and hybrid vehicles. These vehicles

rely on sophisticated electronics for power management and control systems.

Ensuring the reliability of these electronics is of paramount importance, and

PCB potting compound plays a vital role in maintaining their performance under

challenging conditions.

Advancements in PCB potting compound technology have also contributed to

reducing the overall size of electronic components. The ability to create

thinner, more compact protective layers means that manufacturers can design

smaller electronic devices without compromising their reliability. This is

especially relevant in the context of IoT devices, where size constraints often

come into play.

Conformal Coatings for Electronics: Protecting Against the Elements

Conformal coatings have long been a staple in electronic design, serving as

protective layers for PCBs and electronic components. Recent advancements in

this field have given rise to coatings known as "Conformal Coatings for

Electronics." These coatings offer not only protection but also

adaptability and versatility.

Unlike traditional coatings, which can be rigid and challenging to apply to

complex geometries, conformal coatings are more flexible. This flexibility

enables them to be applied to a wider range of components, including those with

irregular shapes. The key advantage is their ability to conform to the shape of

the component they cover, providing a snug and protective fit.

The protective properties of conformal coatings are crucial in the

development of smaller, smarter electronics. As electronic devices become more

integrated into our daily lives, they are exposed to a broader range of

conditions, from extreme temperatures to high humidity. Conformal coatings

create a barrier that shields electronic components from these elements,

ensuring their longevity and reliability.

Wearable devices serve as a prime example of where conformal coatings come

into play. These devices are exposed to sweat, rain, and other moisture

sources. Conformal coatings provide a protective shield that allows

manufacturers to create electronics capable of withstanding these challenges

without compromising their functionality or form factor.

In addition to moisture protection, conformal coatings shield electronic

components from dust, chemicals, and even UV radiation. This level of

protection is critical in numerous applications, from outdoor surveillance

cameras to industrial automation systems, where electronic components need to

function reliably in harsh environments.

The Synergy of Electronic Adhesives

These electronic adhesives, Deep Material Underfill Epoxy, PCB Potting

Compound, and Conformal Coatings for Electronics, may each serve distinct

purposes, but they are often used in synergy to create highly reliable and

compact electronic devices.

Consider a scenario where a miniaturized electronic component needs to be

securely bonded to a PCB. Deep Material Underfill Epoxy provides the bonding

and protection, ensuring the longevity and durability of the component.

Simultaneously, the PCB is encapsulated with PCB potting compound to safeguard

it against external elements and further enhance its resilience.

To complete the package, conformal coatings can be applied to the entire

assembly, providing an additional layer of protection. This ensures that the

entire device remains reliable even in challenging environmental conditions.

This approach is particularly critical in industries such as aerospace,

automotive, and industrial automation, where electronic systems must perform

flawlessly in demanding scenarios.

In conclusion, electronic adhesives, including Deep Material Underfill

Epoxy, PCB Potting Compound, and Conformal

Coatings for Electronics, are the unsung heroes powering the innovation in

the electronic industry. Their advancements enable the miniaturization of

electronic components while ensuring their reliability and protection against

environmental factors. As electronic devices continue to evolve and become

increasingly integrated into our lives, these adhesive technologies will play

an ever more prominent role in shaping the future of our interconnected world.

These unassuming glues are, in fact, the glue that powers innovation in the

electronic industry.

Post Your Ad Here

Comments