The Complete Guide for CNC Router Machine Kits

As we all know, CNC router kits are great kits for beginners. It contains all the necessary tools for building CNC without any difficulty for the builder.

Whether it’s a home workshop for a hobby or a commercial workshop for commercial use, FORSUN CNC offers CNC machines for a variety of applications. Determining the components needed to achieve a “first cut” can be difficult, and with the vast number of options available on the market, choosing options for your build can be daunting. This guide is designed to help you identify different options when purchasing your next CNC machine kit.

What are the CNC router machine kits?

Currently, many CNC machine manufacturers offer complete CNC router kits for DIY CNC routers. When you want to DIY a CNC router, you can buy a CNC router kit and follow the instructions to assemble the CNC router parts. Alternatively, you can purchase individual CNC router parts according to your requirements. CNC router beginners may not know what type of CNC machine kit or part to choose. Let’s take a look at the main CNC router parts below.

CNC Spindle

The spindle is the life and blood of CNC machine tools. CNC spindles play a vital role in machining. It uniquely represents the versatility of a router. CNC spindles differ depending on their handling, machining operations, cooling methods, etc.

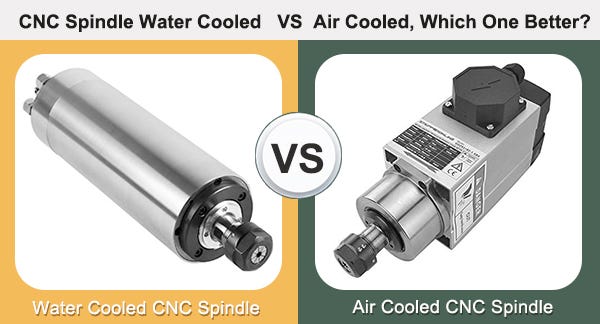

According to the cooling method, there are two main types of CNC milling cutter spindles: water-cooled spindle and air-cooled spindle.

Which CNC router kit is better, air-cooled spindle or water-cooled spindle?

- Cooling effect

Water-cooled spindle, more effective temperature regulation. The water cooling method adopts water circulation to cool the main shaft, and the main shaft temperature after water circulation generally does not exceed 40 degrees. Because of this, water cooling is more suitable than air cooling for longer run time cutting and engraving projects.

- Noise

The water-cooled CNC spindle operates basically silently. The air-cooled spindle generates a lot of noise due to the operation of the cooling fan.

- Service life

The water-cooled spindle of the CNC engraving machine can prolong the service life by replacing the cooling water or industrial chiller. Therefore, as long as the operator pays attention to maintenance, the service life of the water-cooled spindle is longer than that of the air-cooled spindle.

- Convenient

The water-cooled spindle requires an external water tank, water pump, or chiller to use, while the air-cooled spindle can be used directly without any external equipment, so the air-cooled spindle is more convenient than the water-cooled one.

- Operating environment

Water-cooled spindles face two major obstacles in the work environment. First, the water-cooled spindle needs to be connected to other external equipment such as water tanks and pumps. Therefore, it usually takes up more space. If your shop can’t provide this, then an air-cooled spindle may be better for you.

Secondly, water-cooled spindles are not suitable for use in areas with lower temperatures. Especially in the cold winter, when the temperature is lower than 0℃, the cold water tank and water pipes are easy to freeze, causing damage to the main shaft. At this time, the air-cooled spindle is very suitable. If your location is cool most of the time, choosing an air-cooled spindle for your woodworking CNC mill is the best option. It requires no additional external equipment and has good cooling.

FORSUN CNC is a professional CNC router manufacturer, our spindle motors are available in various powers. Both water-cooled and air-cooled spindles have their own advantages. Contact us and we will recommend the most matching configuration for you according to your needs.

ATC spindle VS common spindle

CNC spindle is divided into ATC spindle and common spindle according to the tool change method.

ATC tool changer spindles can be used with linear or disc magazines. This ATC tool changer spindle can automatically change the desired tool during machining without stopping the operation. This greatly speeds up work efficiency and improves product quality.

Ordinary CNC milling machine spindle can only change the tool manually by stopping the CNC milling machine. So the common spindle CNC router kit is suitable for simple woodworking without any complicated processes.

If your product includes multiple engraving styles, the ATC tool changer spindle is your best choice for a CNC router kit.

Motor

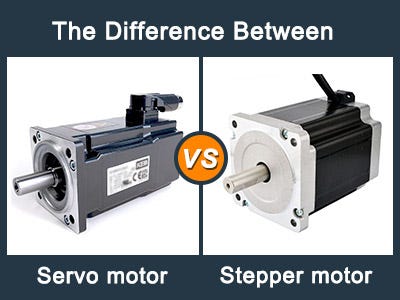

The motor is the heart of the machine — the organ responsible for its function. CNC motors can be stepper motors or servo motors. The motor determines the performance of your CNC machine.

Choosing between a servo motor and a stepper motor can be quite a challenge, involving balancing several design factors. Cost considerations, torque, speed, acceleration, and drive circuitry all play a role in choosing the best motor for your application.

We all know that when we buy a machine, we want to choose the one that is best for our job. When the job is some simple engraving and engraving, a high-speed stepper motor machine is probably the best choice because first of all, it is much cheaper and thus saves your investment cost. Second, the simple working principle of stepper motors makes maintenance easier and less expensive when replacement is required.

When your job requires 3D work, the advantage is that we have servo motor-based machines. Its signal feedback function can stop if any problem occurs during the work, so we can check it immediately.

Whereas with stepper motors, the machine continues to work until it is too late and you have to throw away the current workpiece.

Also, servo motor machines can have better-operating speeds than stepper motor machines due to their characteristics. Therefore, it can make your work faster.

Overall, stepper motors are suitable for simple line engraving and engraving machines, such as door making, cabinet making, simple advertising shops. Servo motors are suitable for 3D work machines such as relief engraving, handicrafts, etc.

Table

CNC Router Table to help you with workholding. They are made of different materials, from aluminum-based T-slots to MDF spoilers. The former needs to be replaced periodically when needed.

At present, the common milling table kits are divided into three types: aluminum T-slot CNC milling table, full vacuum CNC milling table, and T-slot vacuum CNC milling table.

The aluminum T-slot router table kit is made of high-quality aluminum, which is resistant to high temperature, oxidation, and corrosion. Mainly used for materials that are not easy to absorb and hollow out thicker or thinner materials, and special-shaped materials. It requires additional clamps to position and hold the workpiece.

The full-slot or T-slot vacuum CNC milling table is made of cost-effective PVC material, which has the characteristics of high hardness, high-temperature resistance, corrosion resistance, and small deformation. It needs to be connected to a vacuum pump. The full vacuum router bench kit is suitable for processing entire circuit boards. While the T-slot vacuum CNC router table has several zones, each zone can be independently controlled by manual control values.

Control system

The control system is the brain of the CNC machine. They interpret CAD/CAM software and perform g-code programming that facilitates mechanical actions. These may be in the form of G-code transmitters such as PlanetCNC or an open-source firmware such as GRBL.

In the face of numerous CNC control systems on the market, many people feel guilty for not knowing how to choose a CNC system that suits them. The products we sell include the MACH3 control system, DSP controller control system, Nc studio computer control system, Taiwan Syntec control system, and other control systems. The following are some of the more common control systems:

- DSP control system

This system allows users to copy created design files to a USB flash drive. Then, connect to the DSP control system via the USB interface and load the file. The DSP control system does not need a computer, which saves space.

DSP control systems are the most common choice for CNC routers such as the advertising industry and 3-axis woodworking machines.

- Syntec control system

Syntec control systems can control more complex processing routes. Even users can design simple routes without the need for a computer. The high-precision Syntec control system is a closed-loop control system suitable for servo systems.

Generally, it is more suitable for machines with higher configuration, such as automatic tool changers, CNC forming machines, CNC centers, etc.

- MACH3 control system

MACH3 is an open CNC system, the advantage of which is that the system has various functions such as pitch error compensation, backlash compensation, tool length compensation, tool radius, and wear compensation.

The system is mainly used for fully automatic multifunctional mini CNC engraving machines, woodworking machinery.

The control system needs to work perfectly with the CNC machine. If you have questions about choosing a control system, we are happy to offer some advice.

Rail

As advanced mechanical processing equipment, CNC woodworking engraving machine, its advanced engraving precision, strength, and speed are the most basic performance. Choosing a high-speed, high-precision guide rail for a woodworking CNC milling machine can go a long way in your business.

Linear guides have low cost, a short production cycle, and easy installation, and are suitable for small-format fine carving. So it is the best choice for a small CNC router or a desktop CNC woodworking machine. The linear guide has the advantages of strong bearing capacity, stable operation, low friction resistance, and high positioning accuracy, and is suitable for large-format precision engraving. It is an ideal CNC router kit for stone CNC engraving machines, woodworking engraving machines, foam engraving machines, etc.

Transmission Systems

- Rack and pinion

The rack and pinion is an upgraded version, with high speed and low environmental requirements. Compared with the ball screw drive, the X-axis and Y-axis of the wood carving machine are driven by rack and pinion, and the Z-axis ball screw drive and the service life is relatively long. The rack and pinion drive is suitable for large-scale CNC wood engraving machines, which are easy to maintain and are generally equipped with a manual oiling system. The wood carving and engraving machine are mainly suitable for the processing of woodworking products, such as paint-free doors, cabinet doors, solid wood doors, screens, and other plate cutting, hollow carving, embossing, and can also be used for processing stone, marble and granite.

- Ball screw rod

The ball screw is an original transmission method, which is characterized by high precision, slow running speed, high environmental requirements, and relatively short life. The Y-axis should not be too long (the model should not be too large). Mainly used in advertising, wood products, small handicrafts, pumice, and so on. Any material can be engraved according to different router tools.

Should I buy a CNC router kit or a finished CNC router?

If you don’t mind the hassle, have enough time and technical knowledge, and are willing to DIY a CNC router machine, then buying a CNC router machine kit might be a good option. It can exercise your design ability and hands-on ability in the process of assembling CNC router parts. At the same time, this may save you a lot of money.

Buying a CNC router kit and assembling your own CNC router parts may only work for small or simple machines. So, if you are a hobby or just want to DIY a home CNC router, buying a CNC router kit is enough for your needs.

However, if you have a factory or workshop for mass production, a complete CNC engraving machine maybe your best option. The whole machine has strict production and testing process to ensure its excellent quality and stable operation. Even if you are a large-scale furniture manufacturing enterprise, a CNC engraving machine can achieve long-term, heavy-duty, high-intensity cutting work. Complete CNC engraving machines are available in a variety of specifications and can be customized to your needs.

To sum up

The CNC router kit is a great benefit for anyone who wants to build quality CNC machines.

Many buyers find themselves dissatisfied with their purchases. This is simply because more research needs to be done when investing in expensive equipment. Therefore, there are several important aspects that you must consider before planning to purchase your first CNC machine tool kit.

Post Your Ad Here

Comments