Sheet Metal Fabrication: Tips From Master Fabricators

Meta Description: Get valuable information from top master fabricators. Learn about the sheet metal fabrication process and the various benefits it offers.

If your company recently got into custom sheet metal fabrication, you probably have a ton of questions. Even if you have done this for some time, considering how quickly technology changes, you might want to make sure that you are up to speed on the latest options.

Fortunately, several top master fabricators shared valuable insights about precision sheet metal fabrication. With their expert advice, you can avoid making costly mistakes. The following are five specific tips for this particular manufacturing process:

- Choose the Appropriate Material

While that might seem like a no-brainer, several fabricating businesses use the wrong materials for their projects, which can be devastating. Fabricators from reputable sheet metal fabrication companies agree that of all costs associated with this process, material ranks number one.

It is essential that you select the right type of metal and its gauge, otherwise known as thickness. Keep in mind that there is a special calculation for gauges in the US, which equates to weight in pounds per square foot per square inch of thickness. If you use precision sheet metal fabrication to produce quality finished products but need to follow a tight budget, carbon steel is the least expensive. Next, is aluminum followed by stainless steel.

- Limit Use of Tight Tolerances

Experts from trusted sheet metal fabrication companies also point out the importance of limiting tight tolerances when fabricating designs. A common mistake made by fabricators is creating prototypes using unnecessary tight tolerances call-outs on virtually all dimensions. That includes distances, radii, hole diameters, and so on. Why is this important? The tighter the call-outs in a design, the more a finished product will cost.

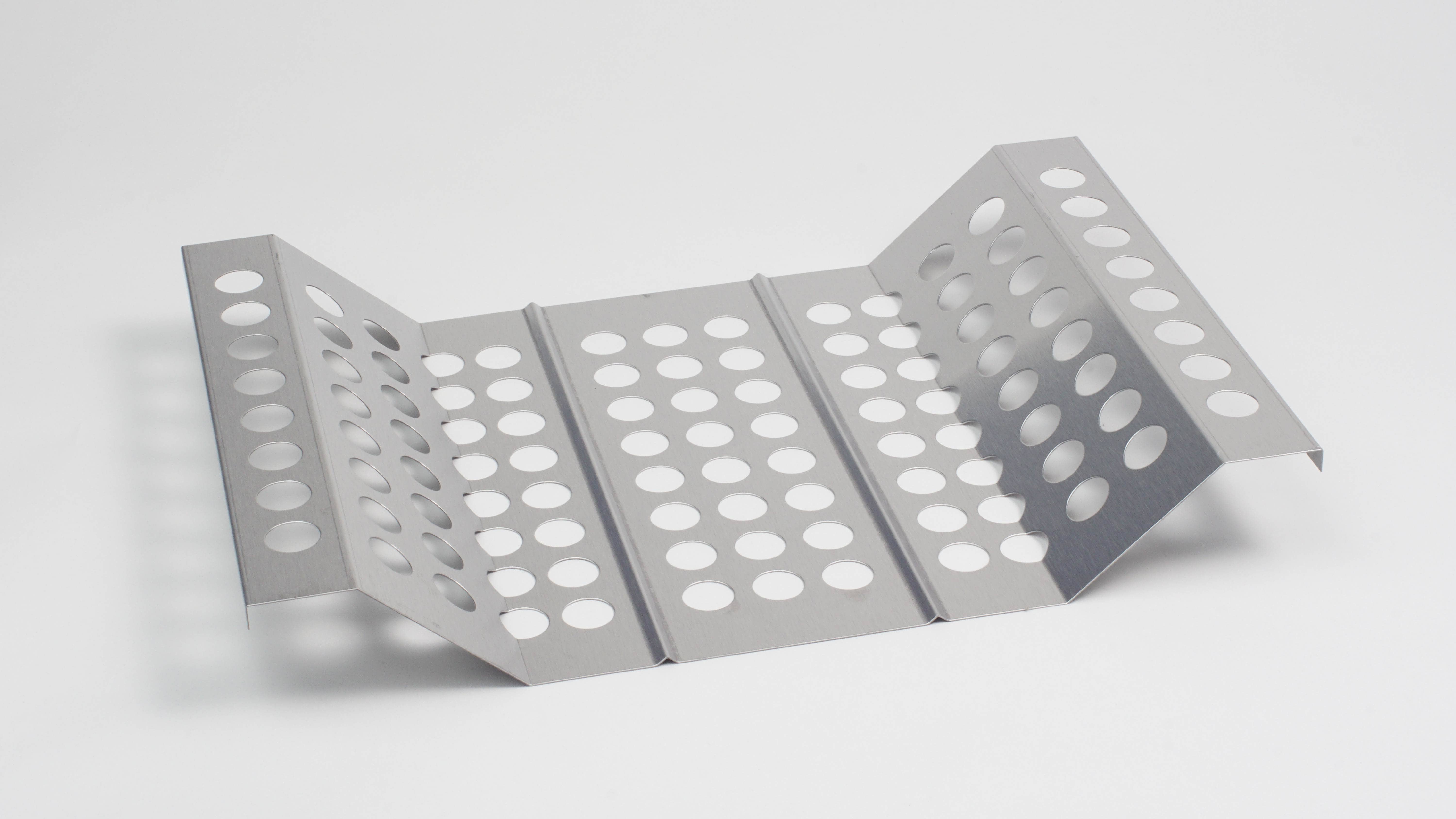

- Simplify Folds

For custom sheet metal fabrication, the more intricate the design, the more expensive the product. To product quality yet keep costs down, consider simplifying the angles on bends. When working with sheet metal, a good rule to follow is to select a radius equal to or greater than the metal’s thickness.

- Keep Bend Orientation Uniform

Even state-of-the-art equipment has limitations. For example, it cannot bend an object in a different direction unless first reorientating it. Every time you physically adjust the metal, it costs more money. This is why experts in the field of precision sheet metal fabrication suggest that manufacturers keep bends on the same bend plane going in the same direction.

Consider Outsourcing Your Fabrication Needs

If you have any concerns about custom sheet metal fabrication, Weldflow Metal Products can assist. As a leading company in this area, we have experts who can tackle a project on your behalf. To get more information, contact us today.

Post Your Ad Here

Comments