How To Choose The Perfect Food Grade Pumps

Kijeka Pumps in the food and beverage industry must adhere to strict requirements to protect the product’s integrity. Include the following factors when choosing a food-grade pump: flow rate, product specifications, construction materials, and any approval conditions.

Flow rate

Flow rate refers to the quantity of liquid that comes through the pump in a predetermined period of time, generally measured in litres per minute or hour. In this latest post, we have to go into how to calculate the flow rate.

Matching a pump’s flow and pressure rating to the flow rate and pressure needed for your process is the key to choosing the right pump. As a result, it’s important to understand the site’s requirements.

The product’s characteristics

Viscosity

The viscosity of your product indicates how thick or runny it is. When choosing a pump and calculating the flow velocity of a process device, this feature must be taken into consideration.

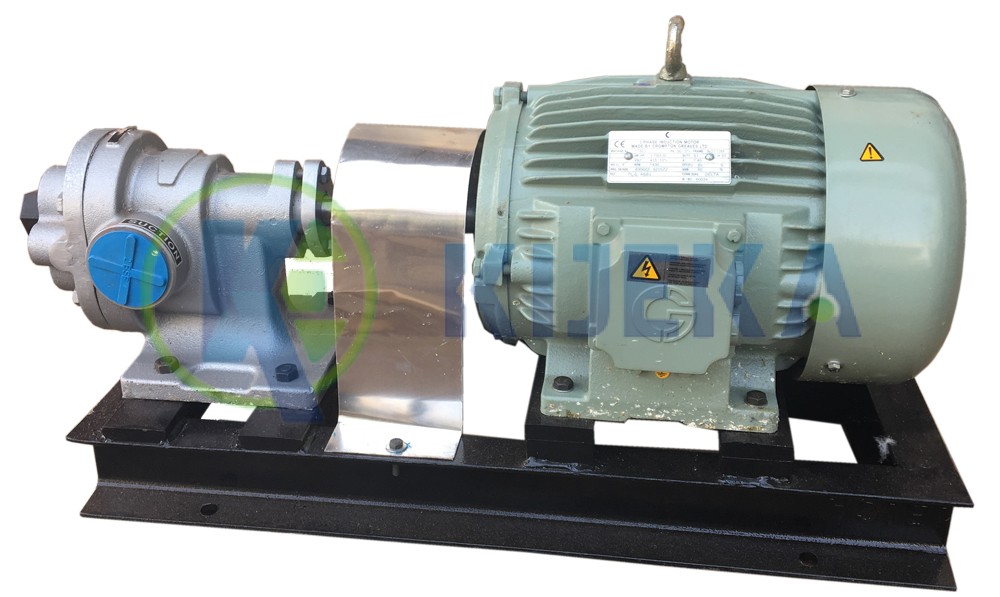

High Viscous Liquid Transfer Pump are preferred by Kijeka Engineers if the product is high viscous. In comparison to other types of pump technology, these are specifically designed to handle viscous fluids, run at low speeds, and transfer lower levels of compressive energy to the fluid.

Centrifugal pumps, on the other hand, are acceptable if the product has low viscosity. Centrifugal pumps produce a lot of compression in the material, so they can only be used for low viscous liquids.

Material

Materials that change their properties while ‘worked’ are known as sensitive items. These are also known as non-Newtonian liquids, and their viscosity changes as the shear rate is increased. Ketchup or salad cream are examples of these liquids. Newtonian liquids, on the other hand, maintain their viscosity despite the shear rate.

If you’re pumping shear-sensitive materials, a pump with gentle pumping action is essential. Shear-sensitive devices are often used in diaphragm and peristaltic hose pumps. Centrifugal pumps are ineffective because they shear the product, causing it to lose its integrity.

Materials for construction

The pump materials are one of the most important parts to remember. Pump failure, downtime, and/or costly repairs can occur if these are incompatible with the ingredients being pumped. Sanitary pneumatic drum pumps are usually made of stainless steel and provide operators with safe and healthy storage and transportation.

Chemicals used for cleaning are an important factor that is often ignored. The pump’s structure and substrates must be familiar with the facility’s cleaning solutions and clean-in-place (CIP) specifications, in addition to the product itself.

When the pump material or seal, as well as the pump itself, are compatible with the food ingredient, but not with the caustics used to clean the pumping system, faults may occur. If the facility does not use caustics and instead relies on compressed air cleaning, the pump must be strong enough to sustain temperatures.

Approval requirements

Most food and beverage equipment manufacturers are experienced with regulatory requirements and can provide guidelines to ensure that your manufacturing is safe and effective.

It is always better to approach the pump manufacturer if you are unsure. They will be able to issue certification that specifies conformity with industry requirements or standards.

If you won’t to buy a food greade pumps contact us and we will provide you a effective, efficient and quality of kijeka pumps. we have 40+ years of experience in material handling equipments.

Post Your Ad Here

Comments (1)