Describing the Top Benefits of Using Zinc for Die Casting

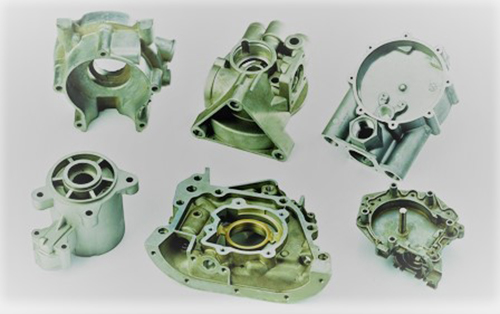

The process of forcing molten metal into the mold cavity using high-pressure is known as die casting and it is basically used for the manufacturing of metal parts. Die castings are generally made of non-ferrous metals including zinc, aluminum, magnesium, copper, lead, etc. If talking as of now, zinc is one of the most used metals for the die casting process because of its unique characteristics. As a manufacturer, you should be aware of the main advantages of Zinc Die Casting so that you can decide whether you should use zinc for casting or not.

Before moving ahead, let's understand the die casting process in brief.

Die Casting Process: Manufacturing a strong steel mold is the first step of this process and the mold should be made at least in two parts to enable the removal of castings. Both the parts are mounted to the machine in such a manner that the one remains stable while the other remains movable (can be called the injector part). The main process starts when both the parts are tightly clamped together and then the molten metal is injected into the mold cavity. The molten metal quickly solidifies and then, both the parts of the mold are drawn apart in order to eject casting.

Now the question is why zinc is believed to be a better alternative for die casting than compared to other metals. For this, you need to know the main advantages of China Zinc Die Casting which have been described in this article.

The low melting point of zinc makes it a suitable alternative for casting. In other words, zinc provides a long tooling life and apart from this, less thermal power is required during the casting process.

An excellent ductile ability is another reason why many manufacturers prefer zinc for the die casting process as it becomes easy to produce castings having complex designs.

The low cost of zinc eventually makes it an economical option, which means you can make a good profit with inexpensive Zinc Die Casting.

It provides better resistance to corrosion and also remains inert in many organic liquids, which is undoubtedly a great advantage.

It becomes the best alternative when castings are required to be lightweight and strong because zinc is not that heavy.

Precise surface finishing is another great characteristic of zinc castings.

Post Your Ad Here

Comments