Connecting Excellence: The Evolution of Epoxy Adhesive Components

In the realm of adhesive technologies, the evolution of epoxy adhesives has

been nothing short of revolutionary. As industries continue to demand stronger,

more resilient bonding solutions, two-component epoxy adhesives have risen to

the occasion, becoming the cornerstone of modern bonding applications. This

article delves into the intricacies of two-component epoxy adhesives, exploring

their multifaceted applications, with a focus on epoxy

potting compounds for electronics and the cutting-edge DeepMaterial

underfill epoxy.

The Rise of Two-Component Epoxy Adhesives

Two-component epoxy adhesives have become the gold standard for many

industrial applications due to their exceptional strength, durability, and

versatility. Comprising a resin and hardener that are mixed in specific ratios,

these adhesives undergo a chemical reaction upon blending, transforming into a

robust and resilient bond. This chemical curing process sets them apart from

their one-component counterparts, offering enhanced performance and

reliability.

One of the key advantages of two-component epoxy adhesives is their ability

to bond diverse materials, ranging from metals and ceramics to plastics and

composites. This versatility has made them indispensable in various industries,

including aerospace, automotive, electronics, and construction.

Epoxy Potting Compounds for Electronics

Electronics have witnessed a paradigm shift in design and functionality over

the years, and with it, the demand for reliable and efficient potting compounds

has surged. Epoxy potting compounds have emerged as the go-to solution for

encapsulating and protecting electronic components from environmental factors,

mechanical stress, and chemical exposure.

These potting compounds provide a protective barrier against moisture, dust,

and other contaminants, ensuring the longevity and performance of delicate

electronic assemblies. The two-component nature of epoxy potting compounds

allows for precise mixing, ensuring optimal performance and adherence to

stringent industry standards.

Moreover, the thermal conductivity of epoxy potting compounds is a crucial

factor in electronic applications. These compounds efficiently dissipate heat

generated by electronic components, preventing overheating and enhancing the

overall reliability of electronic devices.

In the rapidly evolving electronics industry, where miniaturization and

performance are paramount, epoxy potting compounds play a pivotal role in

ensuring the durability and functionality of electronic devices in challenging

environments.

DeepMaterial Underfill Epoxy: Pushing the Boundaries of Possibility

As electronic devices become more compact and powerful, the challenges

associated with thermal management and mechanical stress increase. DeepMaterial

underfill epoxy addresses these challenges head-on, representing a

significant advancement in epoxy adhesive technology.

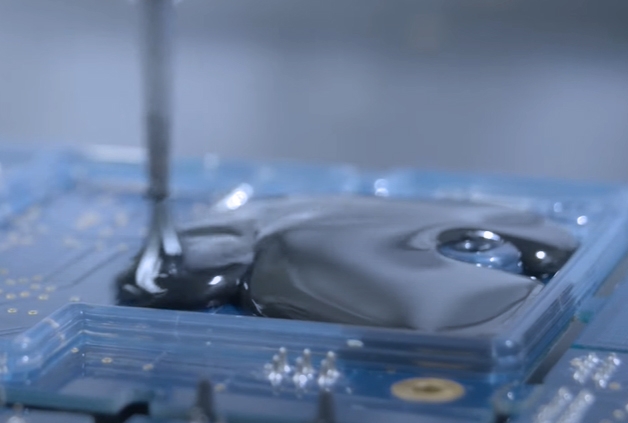

Designed specifically for underfill applications in electronic packaging,

DeepMaterial underfill epoxy provides exceptional thermal conductivity and

mechanical reinforcement. This is crucial in scenarios where electronic

components are densely packed, and heat dissipation becomes a critical factor

in preventing performance degradation.

The unique formulation of DeepMaterial underfill epoxy allows it to flow

into microscopic gaps and spaces, creating a seamless bond between the

electronic component and the substrate. This not only enhances the mechanical

integrity of the assembly but also ensures efficient heat transfer, preventing

hotspots and maintaining optimal operating temperatures.

The adaptability of DeepMaterial underfill epoxy to different substrates and

its compatibility with various electronic components make it a versatile

solution for demanding electronic packaging applications. From mobile devices

and wearables to automotive electronics, the DeepMaterial underfill epoxy paves

the way for more reliable and durable electronic assemblies.

The Sustainability Angle: Beyond Performance

In addition to performance considerations, the evolution of epoxy adhesive

components has also embraced sustainability. Manufacturers are increasingly

focusing on developing eco-friendly formulations without compromising

performance.

Water-based epoxy adhesives, for example, have gained traction as a more

environmentally conscious alternative. These adhesives eliminate the need for

harmful solvents, reducing volatile organic compound (VOC) emissions and

minimizing the environmental impact. As industries strive to meet stringent

environmental regulations and consumer demands for sustainable practices, the

development of green epoxy adhesive solutions is likely to play a pivotal role

in the future.

Conclusion: A Bond That Withstands the Test of Time

The evolution of epoxy adhesive components, particularly the rise of two

component epoxy adhesives, epitomizes the marriage of science and

engineering. From providing robust bonds in industrial applications to

safeguarding delicate electronic components, these adhesives have become

indispensable.

As we delve deeper into the world of epoxy adhesives, the spotlight on epoxy potting compounds for electronics and the groundbreaking DeepMaterial underfill epoxy showcases the adaptability and innovation within this field. The quest for excellence continues, with a growing emphasis on sustainability, ensuring that the bonds formed today not only withstand the test of time but also contribute to a more sustainable and resilient future.

Post Your Ad Here

Comments