1500W Laser Welding Machine: Powerful Precision Welding

A 1500W laser welding machine is a mid-to-high-power laser welder designed to deliver strong, precise welds across a wide range of metals. Positioned between low power bench units and fully heavy-industrial welders, the 1500W model is one of the most versatile and widely adopted laser welding machines today. Its balance of power, speed, and control makes it ideal for small to medium fabrication shops, automotive repair, metal fabrication, and industrial production environments.

Understanding What “1500W” Means in Laser Welding

In laser welding, “1500W” refers to the maximum continuous output power of the laser source. This wattage plays a major role in how deeply and quickly the machine can weld. A 1500W laser falls in the middle range of industrial laser welders and is powerful enough to join metals such as stainless steel, aluminum, copper alloys, and carbon steel with both speed and strength. Its output allows weld penetration deep enough for structural applications while maintaining a small heat-affected zone.

Why Choose a 1500W Laser Welding Machine?

A 1500W laser welding machine offers a compelling mix of power and precision. It’s strong enough to handle thicker materials compared to lower-power welders, but not so powerful that it requires excessive cooling infrastructure or complex automation systems. This makes it useful for workshops that need professional quality without heavy investments in industrial automation or energy costs. Manufacturers, repair experts, jewelers doing heavier work, and prototype fabricators often choose 1500W machines as their core welding solution.

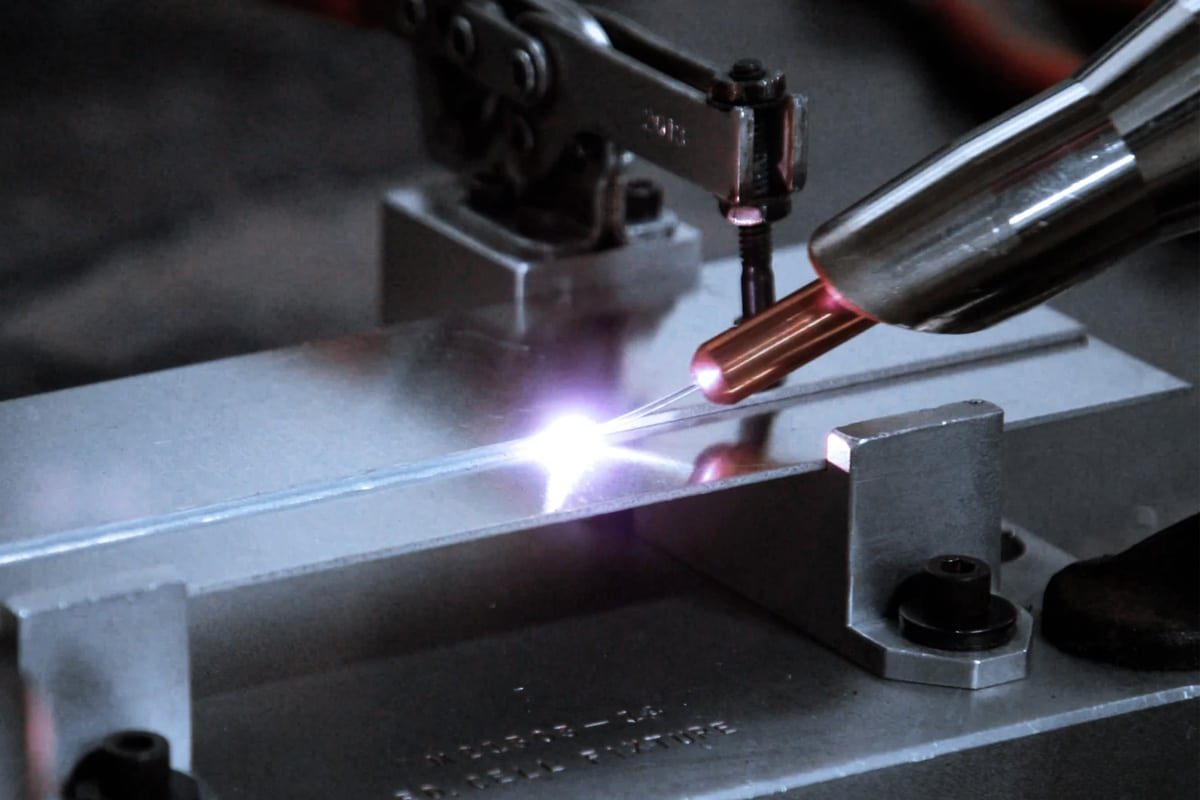

How a 1500W Laser Welding Machine Works

A 1500W laser welding machine uses a highly focused laser beam generated by a fiber laser source to heat and fuse metal surfaces. The laser beam is directed toward the joint, where its energy is absorbed into the material and rapidly heats it to a molten state. As the weld cools, the melted metal solidifies, forming a strong, clean welded joint with a narrow weld seam and minimal distortion.

Control systems allow operators to regulate power, welding speed, pulse frequency, beam focus, and other parameters. This control is especially useful for thin-wall or delicate components, enabling accurate results with precision comparable to high-end industrial welding lines.

Typical Applications of 1500W Laser Welding Machines

A 1500W laser welding machine can be used in a wide variety of industries and applications. In automotive manufacturing and repair, it can weld body panels, exhaust systems, and structural components. In metal fabrication, it is used to join brackets, frames, and sheet metal parts with high strength. Aerospace and defense industries use 1500W lasers for precision welding where material integrity is critical. Electronics manufacturers employ them to weld small but tougher metal parts. Even jewelry workshops benefit when heavier materials require stronger welding capacity.

Advantages of a 1500W Laser Welder

One key advantage of a 1500W laser welding machine is its deep penetration capability compared to lower-power machines. It welds thicker materials with fewer passes and ensures stronger joints. The precision of laser welding also results in minimal heat-affected zones, meaning less distortion of the workpiece and fewer post-weld corrections.

The speed of welding with 1500W lasers is significantly higher than conventional TIG or MIG welding. This improves productivity and reduces labor cost. Another advantage is the clean welding process—laser welds often require less finishing work since they produce narrow, neat seams.

Price Range for a Max 1500W Laser Welding Machine

The cost of a max 1500W laser welding machine can vary depending on features, brand, cooling system, and automation capability. Entry-level fixed 1500W split-type or portable systems typically start from the mid-range category of laser welders, while fully integrated industrial units with advanced control panels and automation options can be significantly higher.

For most users, a basic 1500W laser welding machine designed for manual or semi-automated welding will fall into the $10,000–$30,000 range. Machines with better beam quality, larger work areas, and higher reliability from reputable brands may cost more. Fully automated robotic laser welders with a 1500W source fall into a wider range, depending on robot integration and additional accessories.

Features to Look for in a 1500W Laser Welding Machine

When selecting a 1500W laser welding machine, consider the following essential features:

Laser Source Quality: Look for stable power output, good beam quality (low M²), and reliable fiber delivery.

Cooling Method: Water-cooled systems are preferred for continuous high-power operation because they maintain stable temperatures and prolong component life.

Control System: Precision control of welding parameters, real-time monitoring, and programmable weld sequences enhance repeatability and ease of use.

Safety Features: Laser safety interlocks, protective housings, and appropriate eyewear must be included to ensure safe operation.

Accessories: Fume extraction systems, rotators, fixtures, and vision alignment systems improve efficiency and weld quality, especially in industrial settings.

Manual vs Automated 1500W Laser Welders

Manual 1500W laser welders are typically used in workshops where operators guide the weld with a handheld torch or fixed workstation. They are flexible and suitable for varied jobs.

Automated or CNC-integrated 1500W systems are used in production environments where repeatability and speed are priorities. Automation adds cost but significantly improves output and consistency.

Cooling and Maintenance Considerations

Because 1500W laser welding machines operate at higher power, they generate substantial heat. Efficient cooling systems—usually water cooling with chillers—are essential for reliable operation and long service life. Routine maintenance includes cleaning optics, checking coolant quality, and verifying fiber connections.

Safety in Operating Laser Welding Machines

Operating a 1500W laser welding machine requires proper safety measures. Class 4 lasers are hazardous to eyes and skin. Work areas must be enclosed, operators must wear certified laser safety glasses, and proper ventilation is needed to remove welding fumes. Safety interlocks and training reduce risk and ensure compliance with industrial safety standards.

Conclusion: Why 1500W Is a Popular Choice

A 1500W laser welding machine strikes an excellent balance between power, precision, and cost. It is powerful enough for most industrial applications while remaining accessible for medium-scale workshops. Its versatility in working with a range of metals and thicknesses makes it one of the most practical choices for modern welding needs. When paired with the right control systems and safety features, a max 1500W laser welder delivers professional-grade welds that improve productivity, reduce defects, and elevate manufacturing capability.

Post Your Ad Here

Comments