Mastering Light: The Role of a Precision Optical Lenses Manufacturer in Modern Technology

In today’s technology-driven world, optical lenses play a critical role in countless applications. From healthcare and research to telecommunications and manufacturing, these precisely engineered components are at the heart of many high-performance systems. A professional optical lenses manufacturer is responsible for designing, producing, and delivering lenses that shape, direct, and manage light with incredible accuracy. These lenses are not one-size-fits-all solutions; instead, they are manufactured to meet the specific demands of highly specialized fields. The quality, material choice, and geometry of each lens directly influence how effectively it performs in its intended environment.

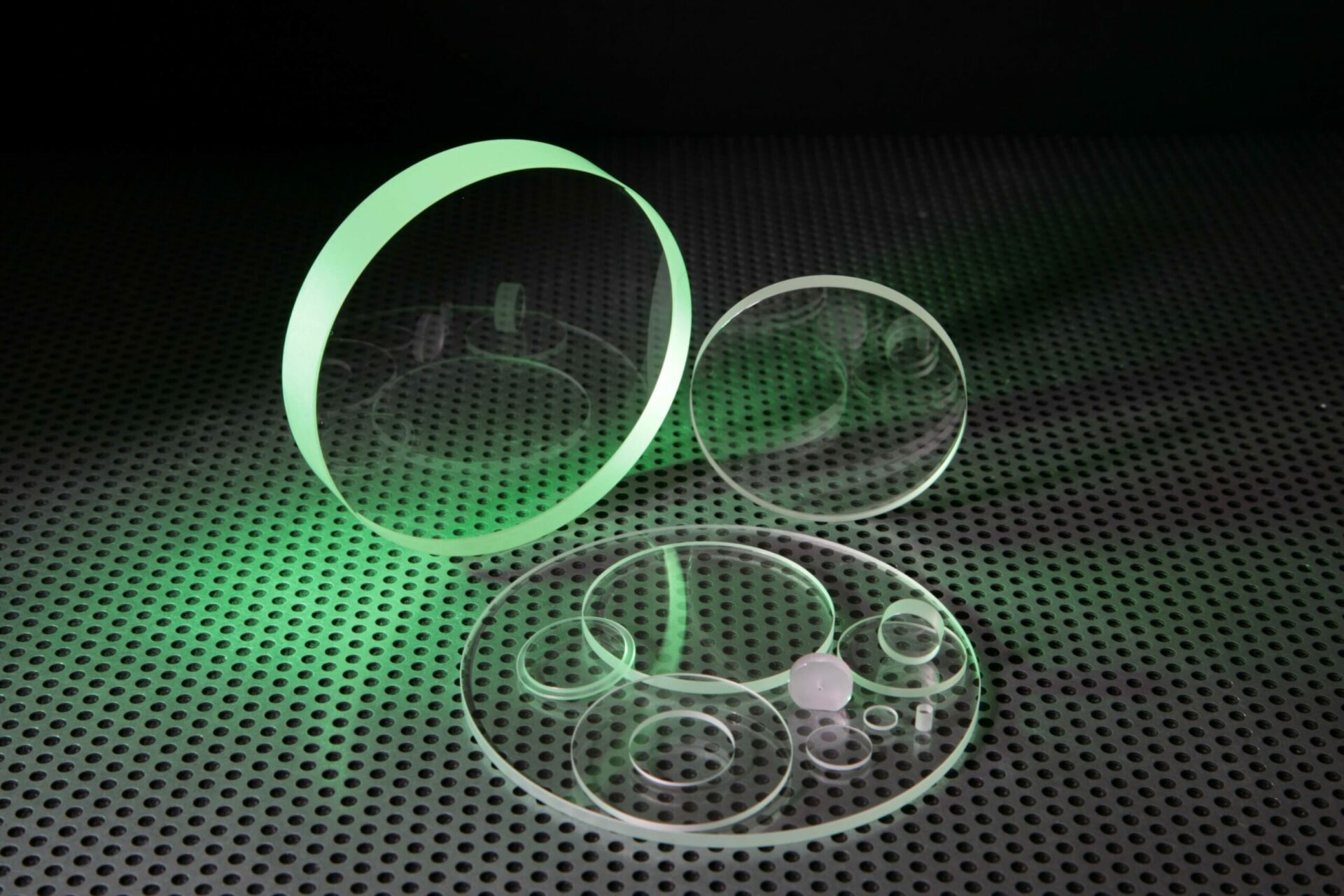

Optical lenses are carefully crafted optical components that either focus or diverge light passing through them. Common types include plano-convex, double-convex, plano-concave, and double-concave lenses. Convex lenses are designed to converge light to a focal point, making them ideal for use in imaging, illumination, and laser focusing systems. On the other hand, concave lenses cause light rays to spread out or diverge, which is beneficial in beam expansion and optical correction applications. Manufacturers must have a deep understanding of optical physics to design and produce lenses that behave as expected when integrated into complex optical systems.

Advanced lens designs go beyond simple focusing and diverging tasks. Achromatic lenses, for instance, are engineered to reduce chromatic aberration—a phenomenon where different wavelengths of light do not converge at the same point. This type of lens is crucial in imaging systems where color accuracy is essential, such as digital cameras, telescopes, and microscopes. Another high-performance design is the aspheric lens. These lenses have surfaces that are not part of a simple sphere, allowing them to minimize spherical aberration and improve focusing capabilities. This makes them perfect for compact devices like smartphone cameras and compact imaging systems, where space is limited but image clarity must be maintained.

Material selection is another critical element in the lens manufacturing process. Different wavelengths of light interact with materials in different ways, which means the material must be matched to the intended application. For instance, infrared applications often require materials like Germanium (Ge), Silicon (Si), or Zinc Selenide (ZnSe), all of which are well-suited for transmitting infrared light. These materials are commonly used in thermal imaging, remote sensing, and infrared spectroscopy. For ultraviolet (UV) applications, fused silica is typically the material of choice due to its high transparency to UV light and its excellent thermal stability. This makes it suitable for high-energy applications such as UV lasers and lithography systems.

An optical lenses manufacturer must also maintain rigorous quality control standards throughout the production process. Precision is paramount, and even the slightest deviation from specifications can result in poor optical performance or system failure. The production process includes grinding and polishing to achieve exact curvatures, followed by coating processes that enhance performance by reducing reflection or increasing transmission at specific wavelengths. Anti-reflective, high-reflective, and protective coatings are applied depending on the operational needs of the lens. These coatings are crucial in increasing durability and improving efficiency, particularly in high-power or outdoor environments.

Customization is another major advantage offered by leading optical lens manufacturers. Many industries have unique requirements that cannot be met with off-the-shelf components. Whether the need is for a specific focal length, material composition, diameter, or coating type, custom lenses are designed to meet precise operational goals. Through close collaboration with clients, manufacturers are able to design, prototype, and deliver lenses that integrate seamlessly into custom optical systems. This capability is especially valuable in industries like aerospace, defense, and biotechnology, where performance and reliability are critical.

In conclusion, optical lenses are indispensable tools in the manipulation of light, and a skilled optical lenses manufacturer is key to producing these components to exact standards. By offering a wide range of lens types, specialized materials, and advanced customization options, manufacturers enable breakthroughs across scientific, industrial, and consumer markets. As technology continues to evolve, the demand for precise, reliable optical lenses will only increase, making the role of expert manufacturers more important than ever.

Post Your Ad Here

Comments