When to Choose Puf Insulated Panels for Your Clean Room or Cold Storage Needs

In industries that rely on temperature-controlled environments, such as pharmaceuticals, food processing, and biotech, maintaining precise temperature control is essential. Whether you are setting up a clean room or cold storage facility, choosing the right materials is paramount to ensuring the efficiency, safety and longevity of your operation. One of the most advanced solutions for this purpose is the Puff Insulated Panel.

But when should you consider choosing puff insulated panels? Let's look at the key factors that will guide your decision-making process.

What Are Puf Insulated Panels?

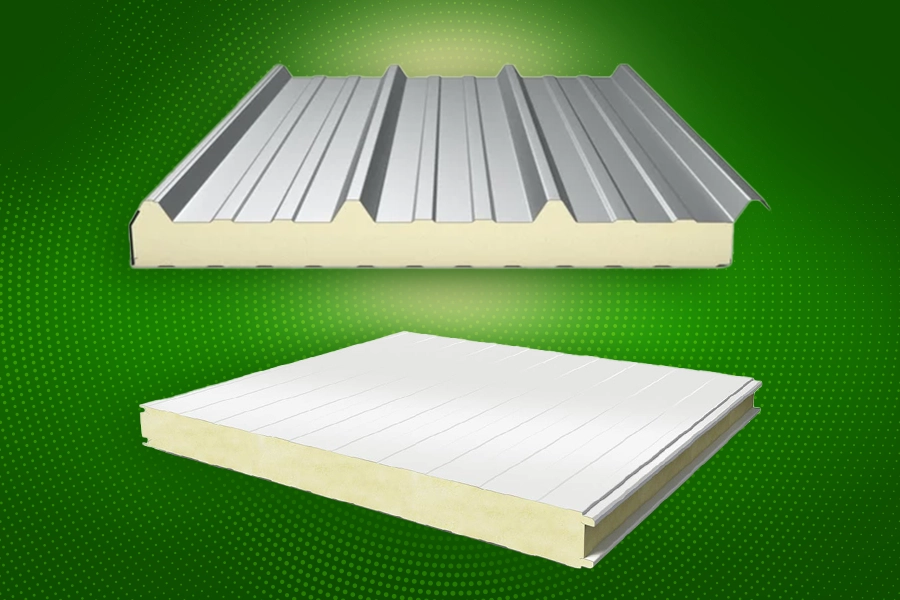

PUF insulated panels are sandwich panels made from a polyurethane foam (PUF) core, sandwiched between two durable outer layers, usually pre-painted galvanized steel or aluminum. The PUF core provides excellent thermal insulation, making these panels ideal for environments that require strict temperature regulation, such as clean rooms and cold storage units.

PUF insulated panels are sandwich panels made from a polyurethane foam (PUF) core, sandwiched between two durable outer layers, usually pre-painted galvanized steel or aluminum. The PUF core provides excellent thermal insulation, making these panels ideal for environments that require strict temperature regulation, such as clean rooms and cold storage units.

When to Choose Puf Insulated Panels

1. When energy efficiency is a top priority

One of the main reasons businesses choose puff insulated panels for clean rooms or cold storage is their energy efficiency. The puff core provides superior thermal insulation, significantly reducing the energy required to maintain a stable internal temperature. This reduces operating costs over time, especially in environments where 24/7 cooling or heating is required.

If you are building or renovating a facility and want to reduce energy consumption while ensuring optimal performance, puff insulated panels are the best choice.

2. When fire safety is important

For industries such as pharmaceuticals and food processing, fire safety is a top concern. Puf insulated panels are designed with fire retardant properties, specifically PIR (polyisocyanurate), which provides excellent fire resistance. This is important to maintain safety standards and protect sensitive products from fire hazards.

If your facility requires high fire resistance to comply with safety regulations and reduce the risk of fire spreading, puff insulated panels are an ideal choice.

3. When you need durability and low maintenance

Another factor that makes puff insulated panels stand out is their durability. These panels are moisture-proof, weatherproof, and long-lasting, making them perfect for environments that require minimal maintenance. Clean rooms and cold storage units are often exposed to harsh conditions including temperature extremes and humidity fluctuations, and puff insulated panels are designed to withstand these stresses over time.

If you are looking for long term performance and low maintenance, Puf Insulated panels will give you the reliability you need.

4. When you need fast and efficient installation

Puf insulated panels come pre-assembled, making installation faster and more efficient than traditional construction methods. Since these panels are designed to be modular, they can be quickly assembled on site, reducing overall construction time and costs.

If your project has a short timeline and you need to get your clean room or cold storage facility operational as quickly as possible, Puf Insulated Panels will streamline the process and ensure construction is completed on time.

5. When sustainability is a priority

In today's world, businesses are increasingly concerned about their environmental footprint. Puff insulated panels are environmentally friendly as they are made from CFC and HCFC-free materials. Additionally, their energy-efficient properties contribute to reducing the overall environmental impact by minimizing energy consumption.

If you are aiming for sustainable building practices and want to contribute to a greener environment, Puf Insulated Panels are a sustainable solution for your clean room or cold storage needs.

Applications of Puf Insulated Panels

Puff insulated panels are highly versatile and can be used in a wide range of applications, including:

1. Clean rooms: Maintaining controlled environments for pharmaceuticals, biotechnology, and electronics manufacturing.

2. Cold storage: Ensuring safe storage of perishable goods such as food, pharmaceuticals and chemicals.

3. Modular Building: Providing quick and efficient construction for temporary or permanent structures.

4. Industrial enclosures: Providing insulation for factories and warehouses.

Read More- Why should you use PUF panels in Prefab Construction?

Conclusion

Puff insulated panels are the ideal choice for industries that require precise temperature control, energy efficiency and fire protection. If your business is involved in cold storage, clean room construction or any temperature-sensitive application, Puf Insulated Panels provide the reliability, efficiency and durability needed for long-term success.

When energy efficiency, fire safety and fast installation are important to your project, choosing puff insulated panels is a smart and cost-effective solution.

Visit EPACK Prefab for more information on puff insulated panels and how they can benefit your clean room or cold storage project.

Post Your Ad Here

Comments