Common Mistakes Committed While Conducting FEA Analysis?

FEA analysis or Finite Infinite Analysis is one of the most imperative analyses conducted by engineers to correctly assess how a model will behave when it is exposed to varied physical conditions and strains. The set of calculations used the predict mishaps that may occur. This is why, FEA analysis is used in the design phase itself to avoid any future failure or large-scale consequences. This is why, FEA analysis services are quite famous in Brisbane. The FEA analysis services experts here in Brisbane offer their services to varied industries in checking the viability of the project or model. However, sometimes mistakes do occur, some mistakes have a pattern and are quite common. Here, we have mentioned some of them:

1. Inadequate Understanding of the Theoretical Foundation:

FEA requires a thorough understanding of difficult mathematics and engineering topics. Engineers may misunderstand data or make inaccurate assumptions if they do not have a thorough knowledge of the underlying theory. To mitigate this, devote effort to learning the principles of FEA as well as the specific theory underlying the problem you're studying.

2. Geometry And Boundary Condition Oversimplification:

Simplifying difficult geometry or adopting unrealistic boundary conditions can have a major impact on the accuracy of FEA analysis services’ findings. It is critical to achieve a compromise between model simplicity and properly capturing real-world events. Always test your assumptions against real-world scenarios.

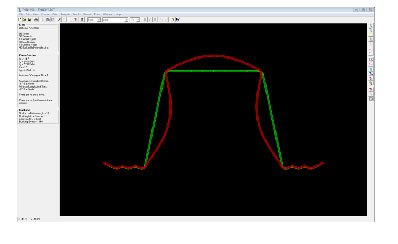

3. Mesh Quality:

Mesh quality has a direct influence on the correctness of your FEA analysis services results. Elements that are excessively big or overly deformed might result in incorrect stress concentrations and unrealistic deformation. To optimise the mesh density, use the meshing instructions offered by FEA software and run mesh sensitivity studies.

4. Wrong Material Characteristics:

Using wrong material characteristics, such as Young's modulus or Poisson's ratio, might provide false results. Check material data to ensure it matches the physical attributes of the materials being utilised.

5. Ignoring Convergence Studies:

Convergence studies assess if FEA findings are robust and consistent when the mesh is improved. Failure to conduct convergence studies can result in untrustworthy results and a false sense of confidence in the study.

6. Disregarding Element Types and Orders:

Different element types (e.g., tetrahedral, hexahedral, etc.) and orders (linear, quadratic) have varied levels of accuracy and computing efficiency. Choosing the incorrect element type or order might influence the overall analysis quality.

7. Disregarding Contact and Interaction Effects:

Failure to appropriately describe contact interactions in simulations with several components or parts in touch might result in unrealistic behaviour. To depict physical interactions, use proper contact definitions and boundary constraints.

8. Wrong Load Application:

Applying loads incorrectly or in the wrong places might result in distorted outcomes. Check the load application points and directions again about the anticipated real-world scenario.

9. Ignoring Numerical Instabilities:

Some issues might cause numerical instability during FEA analysis simulations. Divergence or unrealistic solutions might occur from this instability. Keep an eye out for symptoms of instability and think about improving the mesh, altering solver parameters, or applying stabilisation techniques.

10. Lack of Verification and Validation:

Whenever feasible, FEA analysis service models should be validated against analytical solutions or benchmark cases. Validation against physical testing is also essential to guarantee that FEA findings truly represent reality.

Finite Element Analysis is a valuable technique that, to provide correct findings, demands a thorough and skilled approach. By avoiding these typical pitfalls and constantly honing your FEA abilities, you will be able to confidently utilise FEA to make informed engineering choices, optimise designs, and contribute to safer and more dependable products. Always keep in mind that the accuracy of your FEA findings is directly related to the correctness of your inputs and assumptions.

FEA analysis is an important service offered by engineers in Brisbane and anywhere else. There are some mistakes committed when conducting the analysis.

Comments