What Are the Important Functions of the Piston Ring of a Diesel Generator Set

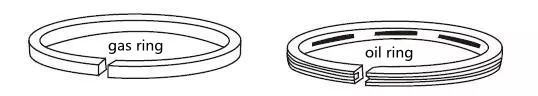

Piston ring is a metal elastic ring with large outward expansion and deformation. It is widely used in various power machinery. It is the core component of diesel generator set. It is assembled into the section and its corresponding annular groove. It can be divided into gas ring and oil ring. The four important functions of piston ring include heat transfer, oil control, support, and air tightness.

1. Heat transfer

The piston of an internal combustion engine works under the action of the high temperature and high pressure gas in each explosion. Therefore, if the heat at the top of the piston is not released and cooled in time, the upper part of the piston will be seriously overheated. As a result, the piston is scratched due to abnormal expansion, at the same time, the piston is worn out early due to the decrease in hardness, the ring stuck due to the deterioration of the oil, and the piston crown and the piston pin seat are damaged due to the decrease in strength. These all bring fatal danger to the normal operation of the engine. It can be seen that the role of the piston ring includes transmitting the high temperature of the piston caused by the combustion gas to the cylinder. that is, cooling the piston. According to relevant information, 70%-80% of the heat in the atmosphere at the top of the piston is dissipated by the piston to the cylinder wall.

2. Control oil

The piston ring slides back and forth along the cylinder wall under high load and high temperature atmosphere. In order to better perform its functions, it is necessary to have a small amount of oil to lubricate the cylinder and piston, but also to properly scrape off the excess oil attached to the cylinder wall to prevent it from running up to keep the oil consumption moderate. In order to control the upward movement of oil, the outer circle of the second gas ring on the piston is generally made into a tapered surface. The tapered surface ring can not only lay an oil film on the sliding surface of the piston when it moves up, but also effectively scrape off excess oil at the lower end of the cylinder wall when the piston ring moves down. This kind of ring is characterized only by its high contact pressure, and because the upper and lower scrapers can act separately, it has good adaptability even for cylinders with poor roundness. More importantly, each scraper not only maintains a seal with the sliding part between the cylinder, but also maintains the airtight effect on the oil between the upper and lower ends of the ring groove, so the oil sealing effect is excellent.

3. Supporting role

The piston reciprocates due to the gas pressure, and this reciprocating motion is turned into a rotary motion through the crankshaft, so the piston ring bears the side thrust component. Therefore, the piston ring fills the gap between the piston and the cylinder, and often contacts the cylinder wall for sliding motion. It not only prevents blow-by and controls oil, but also prevents strong contact between the piston and the cylinder wall. The high-pressure gas also reaches the back gap of the ring, and its pressure presses the outer circle of the piston ring against the inner wall of the cylinder, keeping the piston in a floating state. It can be considered that at this time, the piston ring and the ring groove must be left with proper backlash and backlash. Under normal circumstances, the backlash has two functions: the first is to prevent the ring from sticking in the groove due to the expansion of the piston ring and the piston; the second is to increase the contact pressure of the sliding surface of the piston ring. Play a role in preventing the piston from contacting the cylinder wall strongly.

4. Maintain air tightness

An important function of the piston ring is to maintain the seal between the piston and the cylinder wall and to control air leakage to a minimum. This function is mainly borne by the gas ring, that is, the leakage of compressed air and gas of the engine should be controlled to a minimum under any operating conditions to improve thermal efficiency; prevent the cylinder and the piston or the cylinder and the ring from being caused by air leakage Seizure; to prevent malfunctions caused by deterioration of lubricating oil.

The above is an introduction to the role of the piston ring of a diesel generator set. It is worth noting that the piston ring of a diesel generator set loses its sealing function due to wear faster than the cylinder liner wears to the limit value, so the user is operating the diesel generator set At the same time, it is necessary to always pay attention to the state of the piston ring and deal with it in time.

Diesel generator manufacturer, Guangxi Dingbo Power supply high quality diesel generator and perfect after sales service and give technical support in after-sales. If you have plan to purchase genset, please email to dingbo@dieselgeneratortech.com.

Post Your Ad Here

Comments