Smartest Solutions for the Best Custom Design

by Black White Press Release SubmissionEspecially in the electrical sector, the proper testing of equipment and machinery is a duty that no entrepreneur can handle. The reason is obvious: If a defect occurs on one of your devices and it continues to be used, it can have serious consequences for your employees. A faulty insulation is sufficient and already the electric current from the practical helper to the serious danger.

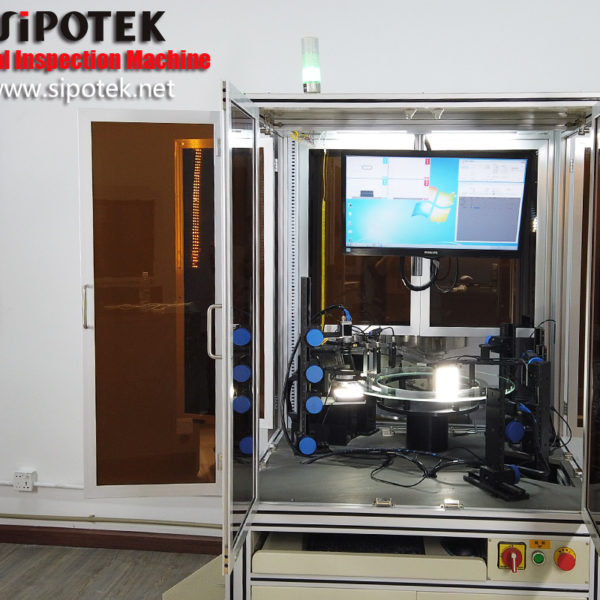

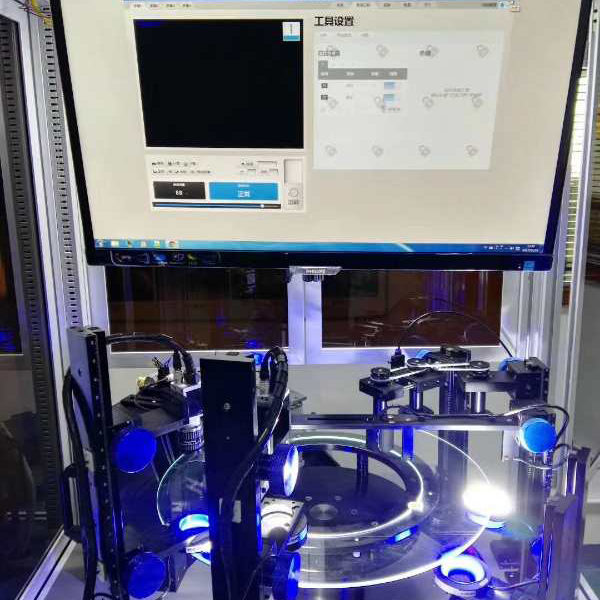

But what must be considered in such an examination? And who is allowed to carry out such a check? There are important questions whose answers cannot be read in a single set of rules. In this guide, we have collected the most important information and give you tips for proper testing of your electrical machines and systems. For the Custom Design Visual Inspection Systems this is important now.

Which equipment must be subjected to an electrical test?

An electrical test is mandatory for all electrical equipment and work equipment used in your company. Whether it's a simple coffee machine, an electrical manufacturing facility, or a telephone, everything that uses electrical energy needs to be checked on a regular basis. Your employees' private devices will also be affected unless your company has a policy prohibiting them from being brought along.

When must electrical equipment be tested?

A check is always required when a device is put into operation or repaired. But regardless of changes to your work equipment, you are obliged to have them checked regularly. How long the intervals between such tests may be depends on many individual factors. Although there are details in the relevant regulations about appropriate deadlines these are only for your guidance and form the legal framework in which your check period should move.

Basically, if a device is exposed to demanding conditions, the occurrence of defects is more likely - so it should be checked at relatively short intervals. Especially electrical components used in bathrooms and other humid environments are affected. If your resources are used in less demanding areas, you can choose your test dates more flexibly. This is particularly the case in the office, where your appliances are not exposed to moisture, excessive dirt or dust. A visit to https://www.sipotek.net/custom-design/ happens to be important.

Who is allowed to check my resources?

The difference is clear here in the qualification: A qualified electrician must definitely have completed a relevant training and have gained at least one year of work experience. Only in this way, as an examiner, can you assess all risks and dangers and prevent possible accidents.

How is an exam running?

An electrical test consists roughly of these components:

1# visual inspection

2# Metrological test

3# Evaluation of the measurement results

4# functional test

5# documentation

For the examiner this means that first the exterior of the test object is scrutinized. Serious defects can be detected or excluded directly. If the device passes the visual inspection, the electrical currents are measured and interpreted. Finally, a simple bump test follows to see if the device is performing the task it was intended to do correctly. If there is nothing to complain about, the examinee has passed the inspection and can continue to be used.

Sponsor Ads

Created on Oct 7th 2019 03:52. Viewed 158 times.

Comments

No comment, be the first to comment.