Plastic Optical Fiber vs. Glass Optical Fiber

Have you ever noticed that you are always turning to optical fibers for high-rate data transmission within your networking systems? Did you give thought to such possibility as installing superconducting fiber cables in even much remoter places? If you did, how do you think about plastic optical fiber vs. glass optical fiber?

Admittedly, telecommunications has undergone significant changes during the past few years. A variety of optical equipment is attributable to this communication evolution, during which optical fiber cables are leading the way. An optical fiber is a flexible and transparent fiber made by drawing glass (silica) or plastic to a diameter slightly thicker than that of a human hair. In recent years, fiber optics are steadily replacing copper wire as an appropriate means of signal transmission.

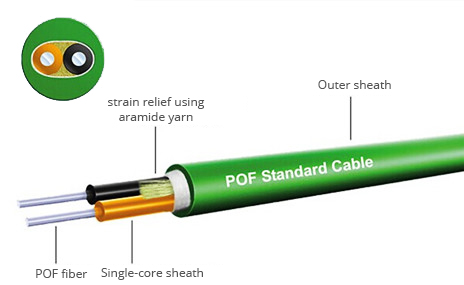

Plastic optical fiber, polymer optical fiber or POF, is an optical fiber which is made out of plastic. Traditionally, it comprises of PMMA (acrylic) as the core (96% of the cross section in a fiber 1mm in diameter) that facilitates the transmission of light, and fluorinated polymers as the cladding material. But nowadays, a higher-performance plastic fiber is used based on perfluorinated polymers. The following picture shows the construction of the plastic optical fiber.

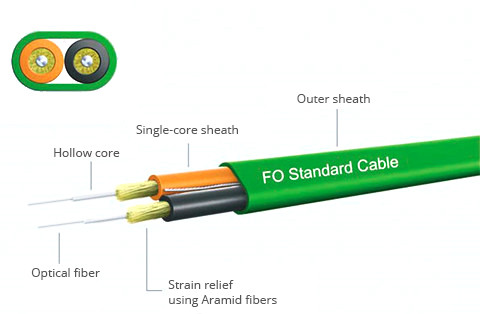

Glass optical fiber, just as its name shows, is an optical fiber made of glass. Being a delicate type of optical fiber, it cannot be cut, spliced or repaired, less resistant to flexibility and accidental breakage. However, this kind of optical fiber is generally ideal for hostile environments. Even when exposed to mechanical stress, high temperatures or chemical substances, it performs normal operation. A figure about the construction of glass optical fiber is available.

Plastic optical fibers differ from glass optical fibers in the following aspects.

- Physical Properties

Plastic optical fibers boast of simpler and less expensive components, as well as greater flexibility, and resiliency to bending, shock and vibration. In addition, they are lighter in weight. All these make them a lower cost alternative to glass fiber or copper at medium distances and bit rates of 10 gbps. In contrast, glass optical fibers need more difficult handling and more delicacy. Being mechanically protected well, glass optical fibers have higher information transmission capacity with lower loss.

- Applications

Plastic optical fibers are commonly used for low-speed, short-distance (up to 100 meters) applications in digital home appliances, home networks, industrial networks and car networks. By comparison, glass fiber optic cables can be applied for longer-distance transmission at higher-speed in office networks. What’s more, they are adept to hostile conditions, more durable than their plastic counterparts.

Optic-fiber signal transmission with plastic or glass optical fibers are finding more and more applications in telecommunication market. Plastic or glass, it just depends on specific conditions. Fiberstore provides both simplex and duplex black plastic optical fibers with other colors available. Besides, other optical fibers are also accessible in Fiberstore, such as single-mode patch cables and multi-mode patch cables. You can visit Fiberstore for more information about optical fibers.

Originally published at http://www.fiberopticshare.com/plastic-optical-fiber-vs-glass-optical-fiber.html

Post Your Ad Here

Comments