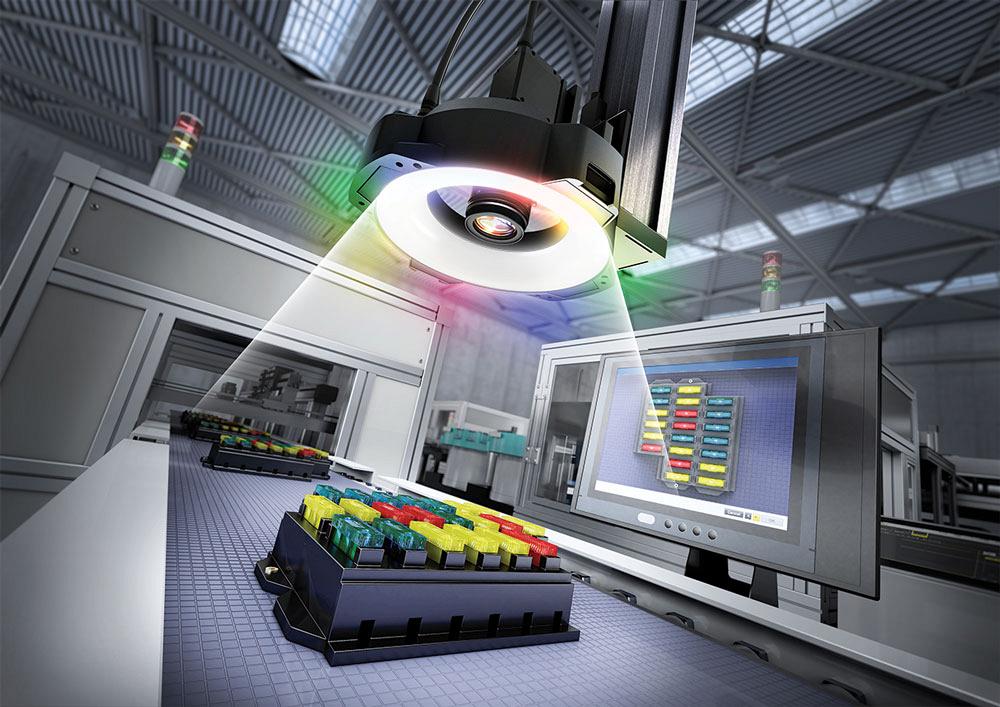

Increasing the quality of products with visual inspection systems

The manufacturing industries these days focus more on increasing the product quality for meeting the market standards. They even aim at investing money on visual inspection systems for gaining more advantages in the production process. It is an important one to know more about the details of a visual inspection system with special attention to invest money according to needs. Many manufacturing units appoint workers to carry out a wide range of jobs. On the other hand, they will result in errors and other hazards that ultimately affect the production to a large extent.

Why visual inspection systems?

Visual inspection allows production companies to carry out inspection works accurately to prevent mistakes, damages, and other issues. It is an ideal one for enhancing productivity in an industry that can help to obtain the desired results. With visual inspection systems, it is possible to save more time while executing important works. Another thing is that they give ways to reduce the expenses in the operations with the most advanced technologies including robot guidance. In addition, they have the capability to detect the defects of parts in machines with the latest technologies.

The importance of visual inspection systems

Quality assurance is the most important step in the manufacturing process before it plays a key role in reducing the defects before selling a product to customers. The visual inspection systems include components such as lights, cameras, lenses, 2D and 3D vision processors. Some of the features offered by them include pattern matching, sorting, color verification, part verification, barcode reading, optical character recognition, and traceability. Industries willing to plan their works efficiently can benefit a lot from the systems which pave ways for reaching the next levels. Furthermore, they can handle complex issues in production by addressing exact requirements.

What are the advantages of visual inspection systems?

The visual inspection systems offer several advantages to manufacturing industries allowing them to accomplish goals in the production process. They include easy adaptability, operational safety, quality maintenance, high-speed inspection, and programming which pave ways for experiencing the desired outputs. These machines can work 24 hours a day which enhance the production volume. It is possible to streamline the operations involved in the production with them that provide ways to increase the quality of a product to a great extent. Industries can even detect the parts with them that requires replacement or repairs.

Getting more details about visual inspection systems

Industries willing to install visual inspection systems should work with a reputed manufacturer for making investments based on the choices. https://www.sipotek.net/vision-solutions/ is the right destination for those who want to know more about the systems, applications, and other features in detail. The company specializes in offering high-quality machines to various industries allowing them to ensure more productivity. Apart from that, production units can fine-tune the systems with all types of production environments letting them set their goals in quality control. Companies can order them at affordable rates which give ways for getting peace of mind from unwanted problems.

Advertise on APSense

This advertising space is available.

Post Your Ad Here

Post Your Ad Here

Comments