How to Reduce Emissions (SO2, NOx, Particulate Matter) in Coal-fired Power Plants?

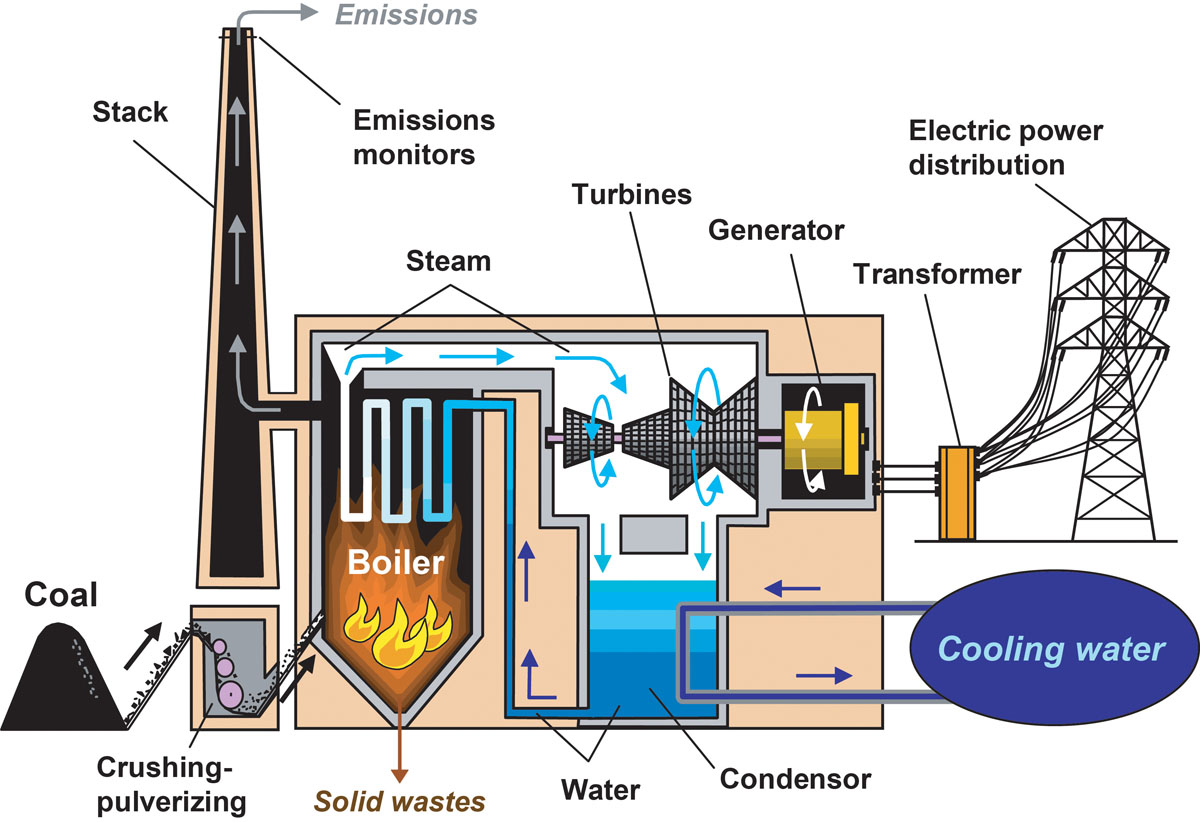

by Rudy P. SysAdmin at howtofindthemoneyMost of Kentucky's coal is used to generate electricity. After coal is mined, it is transported to power plants by trains, barges, and trucks. A conveyor belt carries the coal to a pulverizer, where it is ground to the fineness of talcum powder. The powdered coal is then blown into a combustion chamber of a boiler, where it is burned at around 2,550°F. Surrounding the walls of the boiler room are pipes filled with water. Because of the intense heat, the water vaporizes into superheated (2,000°F) high-pressure (1,000 psi) steam. The steam passes through a turbine (which is similar to a large propeller) connected to a generator. The incoming steam causes the turbine to rotate, creating a magnetic field inside wire coils in the generator. This pushes an electric current through the coils out of the power plant through transmission lines. After the steam passes through the turbine chamber, it is cooled down in cooling towers and it again becomes part of the water/steam cycle.

Emissions Control

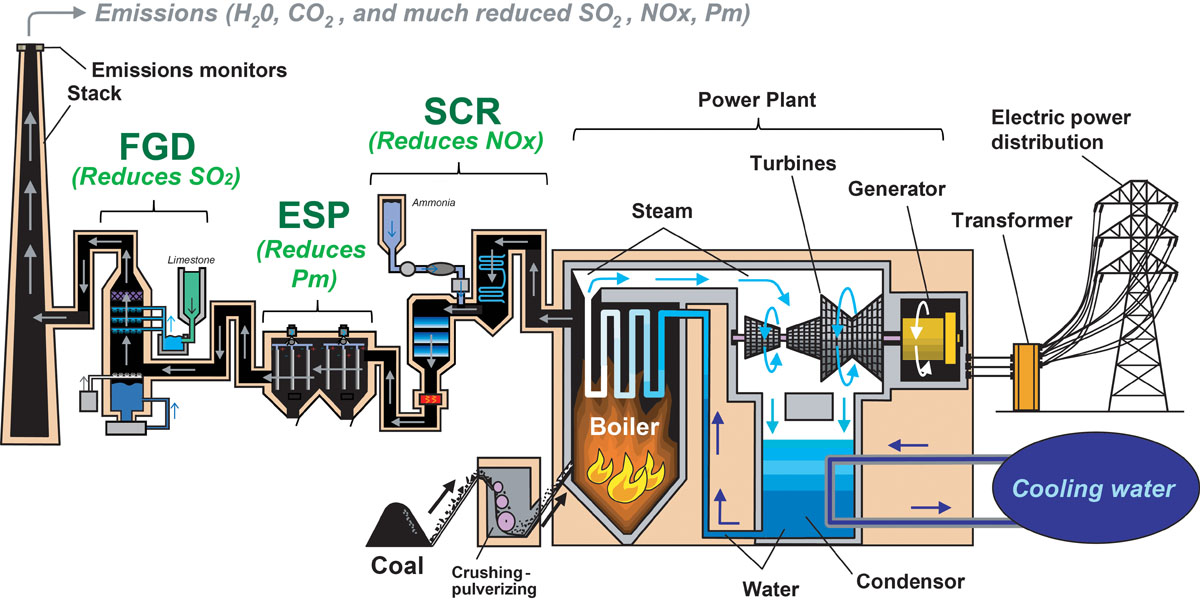

In the United States, gases produced by the combustion of coal in the boiler (called flue gas) must be treated to remove air pollutants before they can be released to the atmosphere through the power-plant stack. Federal regulations limit the amount of nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter that can be released into the air from a power plant. Modern, coal-generated power plants use multiple pollution-control devices to control the flue gas released from the boiler. These devices are not simple filters or devices placed within the exhaust pipes to the stack. Most are large, expensive buildings with complex internal workings. The exhaust stream is redirected through these structures so that pollutants can be reduced before they are emitted to the air.

Selective catalytic reduction and selective noncatalytic reduction units are commonly used to reduce NOx, which contributes to smog and haze. Selective catalytic reduction units use gaseous anhydrous ammonia (NH3) and catalysts to chemically reduce NOx emissions to harmless gaseous nitrogen (N2) and water (H2O). Noncatalytic reduction units reduce NOx formation by injecting urea (CO(NH2)2) into the gas stream without a catalyst. Advanced boilers and fuel changes are also used to reduce NOx emissions.

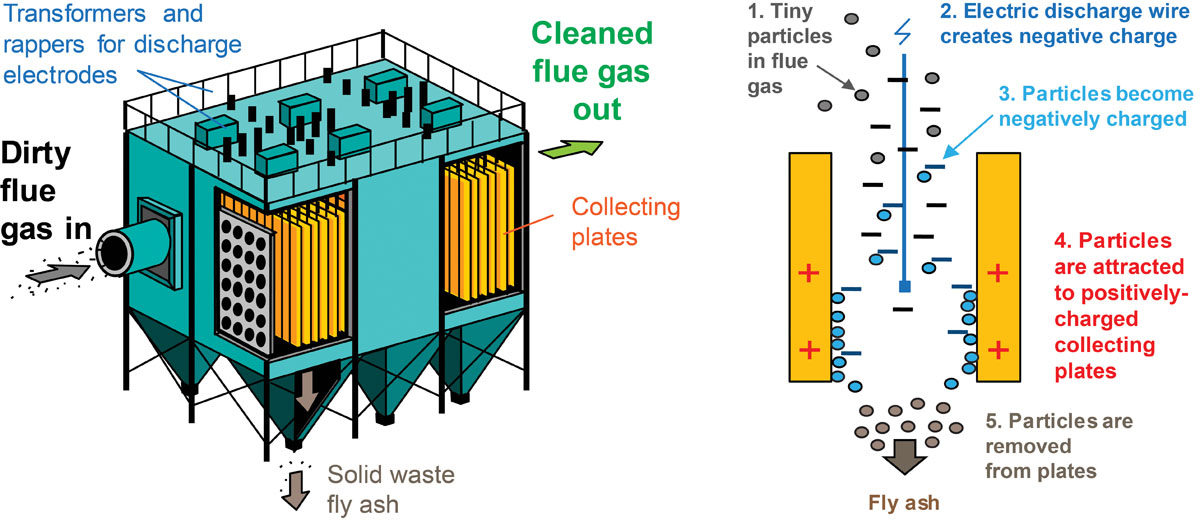

Electrostatic precipitators and filter baghouses are used to trap and reduce particulates in the flue-gas stream. Particles in the gas stream may be only microns in size. Some are 10 to 100 times smaller than the width of a human hair. Filter baghouses use collections of filters to trap particles; the principle is similar to the air filters in a car. Electrostatic precipitators use electrically charged plates to attract particles from the gas stream, capturing more than 99 percent of the solid particles in the gas stream.

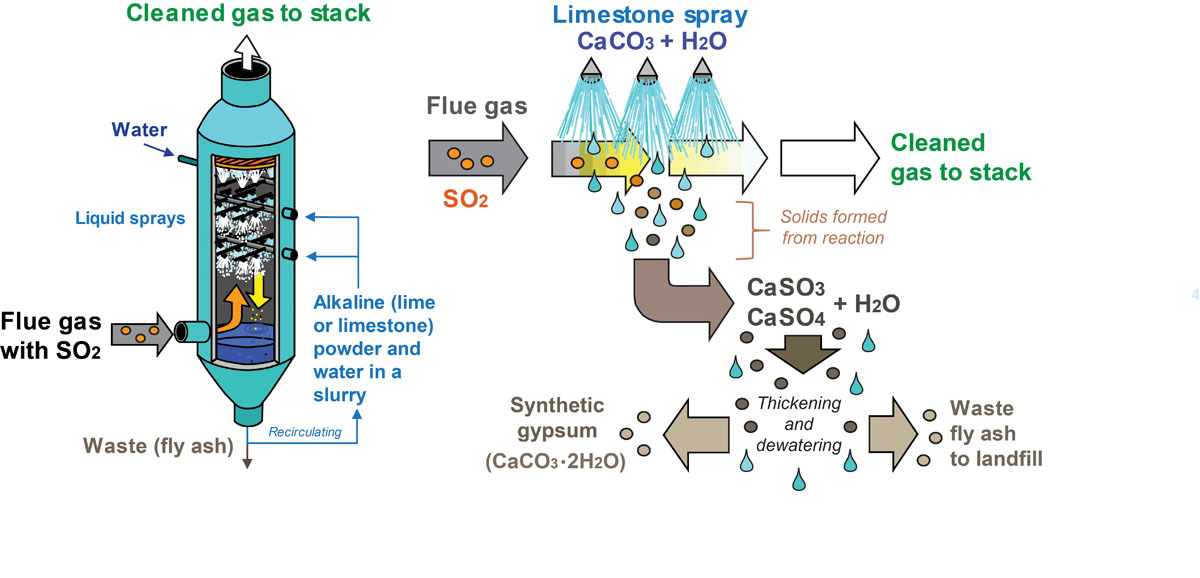

Flue-gas desulfurization units (commonly called scrubbers) are used to trap and convert sulfurous gases from the flue-gas stream. There are several different types of scrubbers. Some use dry limestone powder and others use wet limestone slurry, which is sprayed directly in the path of the flue gas. The limestone reacts with the sulfur in the gases in the stacks. The combination of carbonate (limestone) and sulfur forms solid calcium sulfite (CaSO3) and calcium sulfate (CaSO4)—essentially the mineral gypsum (CaSO4•2H20). Gypsum is a solid that mixes with the liquid sprays to form a slurry (in wet scrubbers) or falls out of the gas to the bottom of the stacks (in dry scrubbers). The fly ash is then collected and either disposed of or used as a byproduct (discussed in the next section).

Another gaseous emission, which has garnered concern because of its contribution to global climate change, is carbon dioxide (CO2). Coal-fired power plants are large point sources for CO2 emissions. Currently, the United States does not regulate CO2 emissions, but regulations have been suggested, and different technologies are being tested to determine their potential viability. One possibility is carbon storage or sequestration.

The 10 largest coal producers and exporters in Indonesia:

Source: Kentucky Geological Survey

Sponsor Ads

Created on Jul 9th 2019 18:31. Viewed 5,149 times.

Comments

No comment, be the first to comment.