How to Check and Adjust Injection Timing for Caterpillar 6D16 Diesel Engine

This instruction will guide you on checking and adjusting injection timing for Caterpillar 6D16 diesel engine.

Caterpillar ET 2020B 2019C 2018A Electronic Technician Software Free Download

Fit an injection pipe 7 onto cylinder No. 1. Point the pipe's other end downward such that fuel flowing out can be seen clearly.

Rotate the crankshaft pulley clockwise (as seen from the front ofmengine) by at least 180° and bring cylinder No. 1 to approximatelym30° BTDC on its compression stroke.

Note:

If the engine is turned in its reverse direction (when stopping the engine or by cranking), the automatic timer may stay in anmadvanced condition. This may not be cancelled by a slightm forward rotation of the engine. Be sure to crank the enginemforward manually by at least 180°.

Feed fuel into the injection pump using the priming pump 8. With fuel flowing out of the injection pipe 7, crank the engine slowly clockwise (as seen from the front of engine).

Ensure that the stop lever 9 at the side of the governor is not in its STOP position.

When the flow of fuel from the injection pipe 7 diminishes, crank the engine more slowly. When the flow of fuel stops completely, stop cranking the engine.

Check that the pointer 10 on the flywheel housing or torsional damper B indicates the value 1° earlier than the correct fuel injection timing.

A: Flywheel

The injection timing in this measurement becomes 15 earlier than the correct injection timing due to the inactivation of the delivery valve spring.

The correct injection timing is indicated on the plate attached on the rocker cover.

If the injection timing should be measured in a dusty location, perform as follows:

Rotate the crankshaft pulley clockwise (as seen from the front of engine) and bring the No. 1 cylinder to 30° BTDC on its compression stroke.

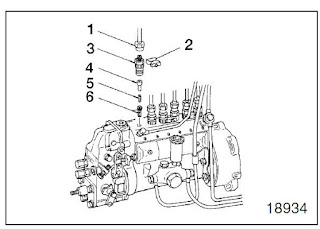

Disconnect the injection pipe 1 with a little amount of fuel remained at the top of the delivery valve holder 3.

Slowly rotate the crankshaft pulley clockwise. When the injection timing is reached, the fuel at the top of the delivery valve holder 3 starts to move.

If the injection timing is out of the specification, adjust as follows:

[Adjustment]

Loosen the nuts 12 that hold the timer case 11 onto the pump drive or air compressor 13.

If the fuel injection timing is overly retarded, incline the injection pump toward the crankcase.

If the fuel injection timing is overly advanced, incline the injection pump away from the crankcase.

Turning the injection pump by one of the gradations inscribed on the timer case flange C causes a 6° change in the injection timing.

Tighten the nuts 12, then check the fuel injection timing again.

If the fuel injection timing is so far out of specification that adjustment with the injection pump is not possible, the engine timing gear and injection pump drive gear may not be meshing correctly. If this occurs, remove and refit the air compressor or injection pump drive.

Air compressor

Injection pump drive

After checking that the fuel injection timing is up to specification,

fit the delivery valve 6, delivery valve spring 5, and stopper 4.

Tighten each part to its specified torque.

2020 Caterpillar SIS CAT SIS Software Download & Installation Service

Post Your Ad Here

Comments