How should you Choose Rubber Sheet for Industrial Usage?

by Sanjeev Yadav SEO ConsultantRubber sheeting is a process by which a layer of rubber is distorted, allowing it to be seamlessly joined against an adjacent geographic layer. The rubber sheet is produced uniquely for various uses in the industrial manufacturing process. A natural rubber sheet is a type of rubber sheet characterised by excellent dynamic, elasticity, and mechanical properties. This sheet is perfect for use as general sealing material. This type of rubber sheet is available in the market in any environment without any specific requirement.

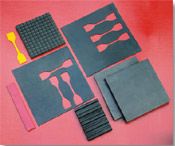

Types of Rubber Sheet

The different types of rubber sheets are as follows-

1. Neoprene rubber sheet offers good resistance to any petroleum products, oil, flame, alkalis, and acids. In industrial applications, this type of rubber sheet is helpful as corrosion-resistant coatings to protect the contents and other electrical applications.

2. Silicone rubber sheet has enormous usefulness in the pharmaceutical industry because they can resist high temperature. This sheet has an extreme tendency of harsh weather resistance, ozone, and other chemicals.

3. Fabric reinforced rubber sheets- This rubber sheet is made from natural or synthetic rubber. This type of rubber sheet can provide strength against high pressure.

The Unique Application of Rubber Sheets

The considerable application of industrial rubber sheets are as follows-

• Some of the popular uses of rubber sheets are in roofing and flooring applications. Rubber provides enormous resistance to substances such as oil, petroleum, ultra violet lights, and oxidising elements.

• Apart from this, it has the capacity to maintain its flexibility even in cold temperatures. The elasticity of this rubber sheet makes it suitable for various shock absorbers, and it is specialised in different machinery mountings to reduce vibration.

• Numerous rubber sheets are used for numerous purposes, such as industrial buildings, agricultural machines, dance studios, garages, dryer pans, and drainage systems.

• A rubber sheet is also helpful in many areas such as footwear, medicine, railways, automotive, engineering, defines, marine, and aeronautics.

• A rubber sheet is helpful in lining storage tanks, railroad tank cars, floor mats preparation, horse stall mats, orthopaedic footwear, and bearing pads.

Rubber Sheet Buying Process

One should consider the following things while selecting any industrial rubber sheet exporter-

1. Thickness- The first thing that one should consider while selecting a rubber sheet is its thickness. This is essential for gasket and sealing applications.

2. Temperature- one should consider the temperature of the rubber sheet to make it functional and practical. Silicon rubber sheet can handle constant temperature between -70 degrees C to 200 degrees C. It makes it popular for many extreme temperature climates.

3. UV resistance- exposure to ultraviolet rays and ozone is a unique detrimental part for many rubber types, including natural rubber and nitrile rubber.

4. Oil resistance quality is another essential factor of rubber sheets. Nitrile rubber is explicitly developed to withstand oil.

5. Hardness, acid resistance, and abrasion resistance are the important things to consider while buying a rubber sheet.

These are the critical things that you should consider while selecting any rubber sheet manufacturer or supplier.

Sponsor Ads

Created on Mar 31st 2022 01:10. Viewed 183 times.

Comments

No comment, be the first to comment.