Enamelled Wire Manufacturers Need What Production Equipment

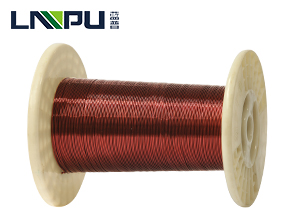

Enamelled wire is an essential component of many electrical devices, from small household appliances to large industrial machinery.

Enamelled Wire Production Process:

The enamelled wire production process typically involves the following steps:

Wire Drawing: The first step in the enamelled wire production process is wire drawing. This involves pulling a copper or aluminum wire through a series of dies to reduce its diameter to the desired size.

Annealing: After the wire has been drawn to the desired size, it is annealed to soften it and make it more malleable. This involves heating the wire to a high temperature and then cooling it slowly.

Cleaning: Once the wire has been annealed, it is cleaned to remove any dirt or debris that may have accumulated during the annealing process. This is typically done using a chemical cleaning solution.

Coating: The next step in the enamelling process is coating the wire with enamel insulation. This is typically done by passing the wire through a bath of liquid enamel. The enamel is then cured by heating the wire in an oven.

Cooling: After the enamel has been cured, the wire is cooled to room temperature.

Sizing: Finally, the wire is sized to the desired diameter by passing it through a series of dies.

Production Equipment Required for Enamelled Wire Manufacturers:

Enamelled wire manufacturers require several pieces of production equipment to produce high-quality enamelled wire. Some of the essential production equipment required for enamelled wire production include:

Wire Drawing Machine: Wire drawing machines are used to draw the copper or aluminum wire to the desired size.

Annealing Furnace: Annealing furnaces are used to soften the wire and make it more malleable.

Cleaning Equipment: Cleaning equipment is used to remove any dirt or debris that may have accumulated during the annealing process.

Enamelling Machine: Enamelling machines are used to coat the wire with enamel insulation.

Curing Oven: Curing ovens are used to cure the enamel insulation by heating the wire to a high temperature.

Sizing Equipment: Sizing equipment is used to size the wire to the desired diameter.

Quality Control Equipment: Quality control equipment is used to test the wire for various properties, including electrical conductivity, insulation resistance, and coating thickness.

Conclusion:

Enamelled wire manufacturers require several pieces of production equipment to produce high-quality enamelled wire. These include wire drawing machines, annealing furnaces, cleaning equipment, enamelling machines, curing ovens, sizing equipment, and quality control equipment.

Comments