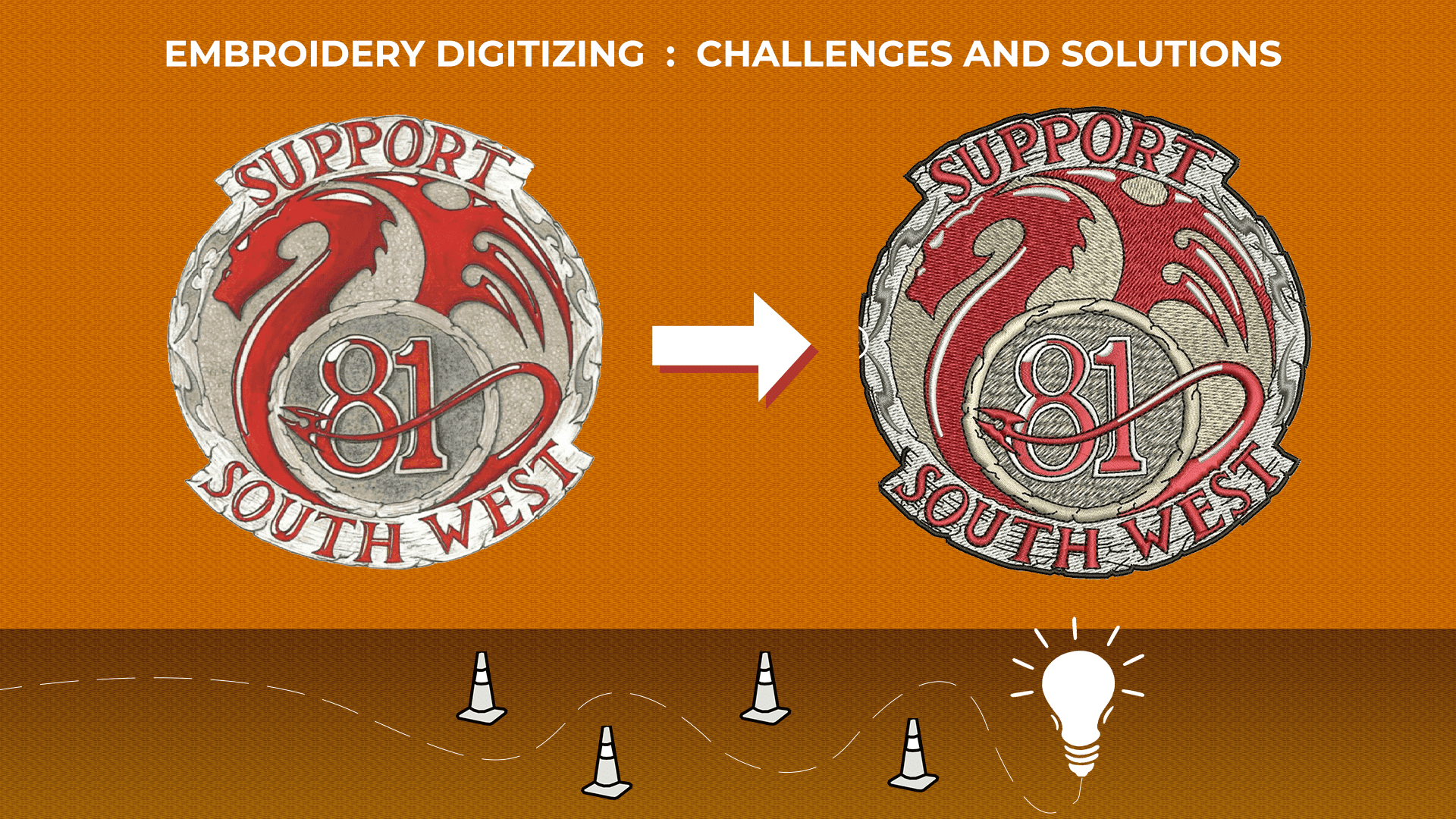

Embroidery Digitization Challenges and Solutions

by Cre8ive Skill We Digitize Your Dreams

The digitizing industry is growing at a fast pace, and so is the associated work. There are several companies available online that offer vector artwork and embroidery digitizing services. Yet, finding one suited to your needs and requirements can be tricky. Moreover, as the industry itself has its own form of creativity and uniqueness. A lot of final design outcome can be attributed to the exhaustive attention to detail. Starting with the work involved in the software to every element on the material needs equal scrutiny and careful examination.

When thinking of getting an incredible embroidery artwork done, the primary concern is finding a reliable company. A digitizing service that is cost effective, dependable and guaranteed results is the holy trinity. A thorough knowledge of the digitizing industry is essential in picking out the right fit for your needs. For that you must first understand how digitizing companies work. With a little online research you can make a lot of headway in the right direction.

If you are in search of an advanced, customer-centric digitizing company that not just meets but also exceeds your expectations and offers competitive prices to boot then you have reached the right place. Crea8iveSkill is all you need. We are the indisputable industry leaders when it comes to comprehensive vector artwork and cutting-edge logo embroidery digitizing services. Having been tenaciously involved in providing holistic digitizing services for decades, we have set a benchmark in the industry.

Crea8iveSkill offers digitized artwork products that are flawless. Our logo embroidery digitizing and vector artwork is unique and of the finest quality. At Crea8iveSkill, we have a large network of expert digitizers, proficient illustrators, and skillful designers. Our dedicated team works tirelessly and endeavor to provide only the

best embroidery digitizing services and vector artwork at the most affordable rates possible.

Embroidery Digitizing: Major Challenges

At

Crea8iveSkill we are well-versed with the workings of the digitizing world. Some of the major issues faced by most digitizing companies is discussed here forth. We will also touch upon some of the solutions one can adapt when faced with similar obstacles during the embroidery digitizing process.

One of the most common difficulties in embroidery digitizing is the widespread thread break issue is another problem that most embroidery machines are susceptible to, and is an inevitable bottleneck in the embroidery digitizing world. In fact, in the digitizing industry, this is a constantly recurring problem.

Beginners or newcomers to the embroidery digitizing industry will find it tough to manage the frequent thread break issue. We aim to share the major causes of thread breaking, how to solve the issue to operate your embroidery machine in hassle free.

How To Prevent Thread Break Problems?

As the name suggests, during the embroidery process, when the thread breaks it can be very frustrating. Especially, for the workers who diligently toil on the various designs. This problem is the most common among the issues that hinder a smooth embroidery process. A smart way to navigate thread breaks is to know how to troubleshoot them. Each thread break is different and therefore, their individual fixes are also different. So, you need to understand and figure out the type of thread break you are having. This will help you avoid future hassles when you encounter a similar problem later.

Types Of Thread Breaks

It is vital to learn the various types of thread or strand breaks that you may encounter during the embroidery digitizing process. There are mainly four main types - Shredding, Clean-breaks, Pop-outs, and False thread breaks.

In machine embroidery, the shredding type of thread break involves the shredding of the thread near the needle. This thread shred problem typically occurs when the needle’s eye is too narrow to fit the thread. The stress and friction caused, results in shredding and breaking of the upper thread.

As the name suggests, when your thread breaks off cleanly, it is a clean-break. This happens if the embroidery machine does not get enough strands for forming the stitches. It is important to ensure that the path of the thread is clear without any hindrance so that the thread moves effortlessly.

When the digital embroidery machine is running, if the thread pops-out of the eye of the needle then that is termed as a pop-out thread problem.

In case of a false thread break, the top portion of the thread is attached to the fabric. The problem arises when the thread break registers in the embroidery machine, when it is not actually broken. Improper tension is one of the chief causes of false thread breaks in embroidery machines.

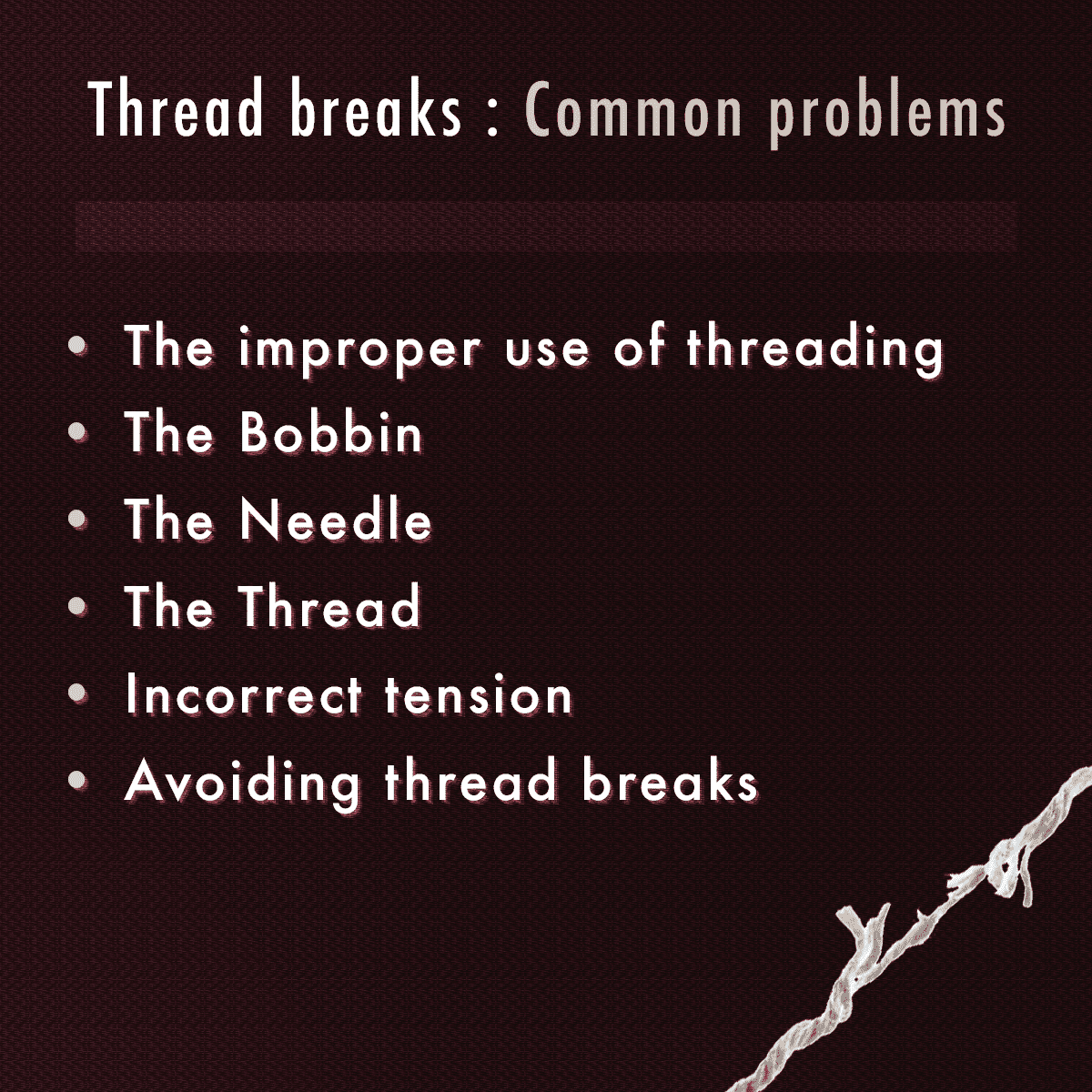

Thread breaks: Common problems

In the

machine embroidery process, it is very important to recognize the type of thread break. Once, you can identify the type of thread break, it is fairly easy to diagnose the rest. Let’s now discuss the common thread breaks that are known to occur during machine embroidery processes.

Thread breaks mostly happen due to a bad design or an unsuitable needle. They may also occur if the plate of the needle is damaged or the needle itself is improperly hooped. The height of the press foot, incorrect timing, incorrect needle depth, and a deficiency of oil on the rotary hook are also contributing factors to frequent thread breaks. However, using sturdy and durable thread varieties can help mitigate a vast majority of these problems.

The thread used in embroidery is typically strong, durable, and consistent in quality. Polyester and Rayon are the two most preferred thread varieties in embroidery digitizing artwork. However, Polyester is recommended by most experienced companies due to its strength, durability and high resistance to color fading. Each problem in embroidery digitizing is caused due to varying agents, but improper strain is the major cause of recurring thread break related difficulties.

The most common problems can be listed as:

• The improper use of threading

• The Bobbin

• The Needle

• The Thread

• Incorrect tension

• Avoiding thread breaks

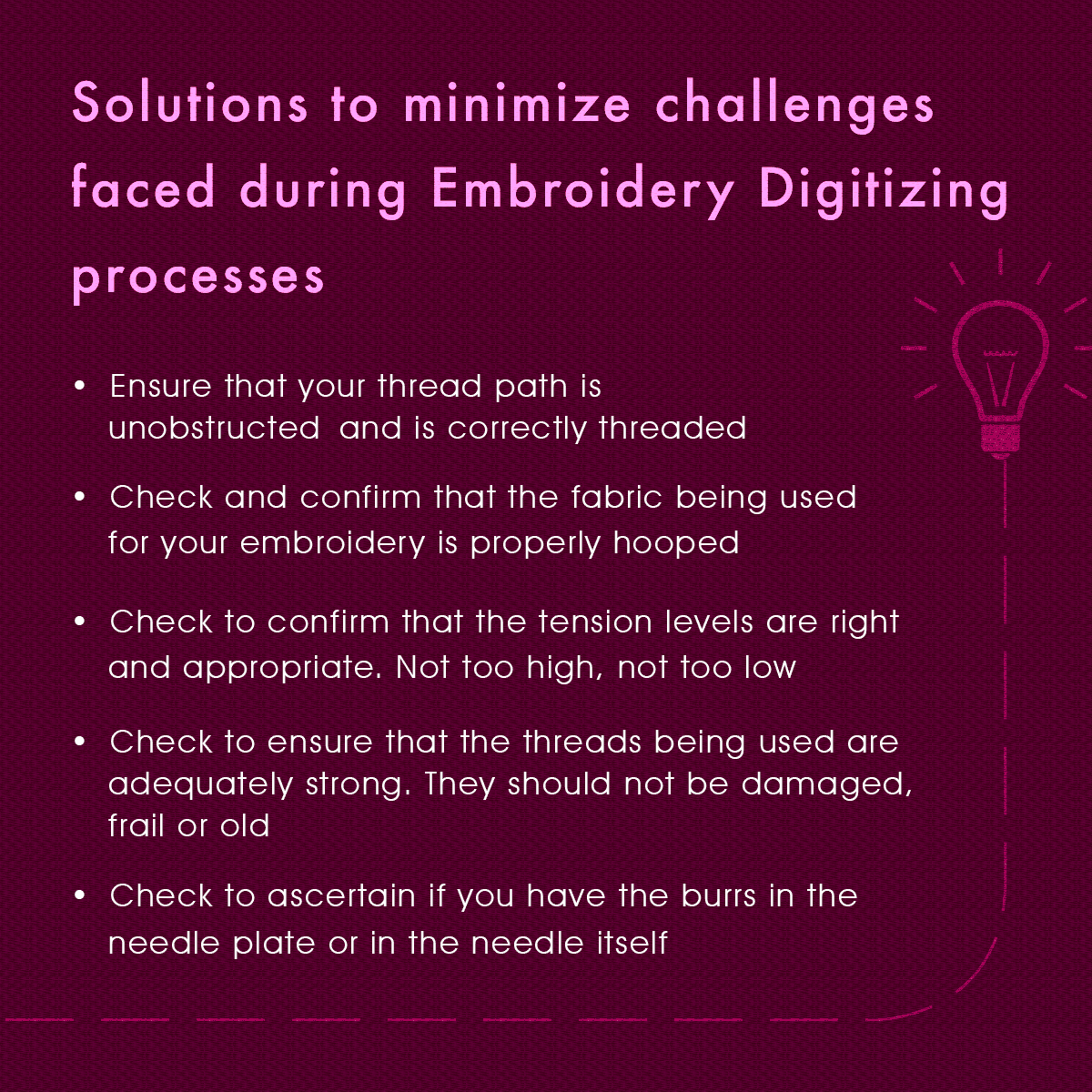

Solutions to minimize challenges faced during Embroidery Digitizing processes

In order to avoid most of the major challenges linked to thread breaks, the first step is to diagnose the problem and then troubleshoot it. Making a proper checklist of these issues as and when faced, while operating the embroidery machine is highly recommended.

• Ensure that your thread path is unobstructed and is correctly threaded

• Check and confirm that the fabric being used for your embroidery is properly hooped

• Check to confirm that the tension levels are right and appropriate. Not too high, not too low

• Check to ensure that the threads being used are adequately strong. They should not be damaged, frail or old

• Check to ascertain if you have the burrs in the needle plate or in the needle itself

When discussing challenges faced during the embroidery process, one cannot overlook the lack of experienced digitizers as a major factor. These consummate professionals are active contributors towards a perfect design outcome. They play a vital role in minimizing major challenges faced during the embroidery digitizing process. Achieving design perfection and retaining the design integrity are additional concerns that digitizers face. Another obvious challenge is the lack of adequate and innovative machinery, and suitable work facilities. Along with, highly skilled and expert craftsmen, Cre8iveskill has a state of art facility that can meet all individual product requirements as well as bulk client needs. Their specialists use cutting-edge embroidery machine software and innovative processes to turn your original design ideas into a fully-stitched reality.

Sponsor Ads

About Cre8ive Skill  We Digitize Your Dreams

We Digitize Your Dreams

254 connections,

14 recommendations,

653 honor points.

Joined APSense since, April 8th, 2020, From Houston, United States.

Created on May 20th 2021 06:55. Viewed 558 times.

Comments

Please sign in before you comment.

Like a very good article, 【 Manifoldblocks.com 】

Aug 23rd 2021 07:05