Display Manufacturing Process with A Precise Automated Robots | BRILS CORPORATION

BRILS CORPORATION was established in South Korea in 2015. Since then, it has been providing customized and standardized systems that are tailored to the specific needs of clients in cutting-edge industries such as automotive, semiconductor, display, secondary batteries, and specialized products. Its market extends beyond domestic borders and includes major international markets such as the United States, Czech Republic, Poland, Mexico, Brazil, Russia, India, Indonesia, Malaysia, and Vietnam. Additionally, the company is dedicated to meeting the unique requirements of customers in various industries and regions.

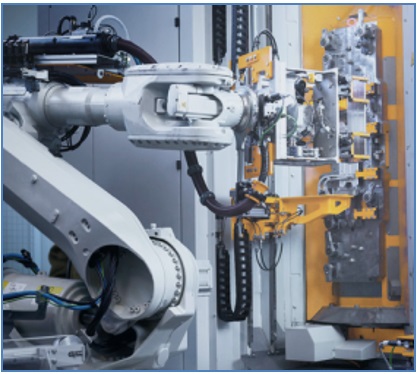

Brils Corporation’s Display Manufacturing Robots

As an display manufacturing robots company, Brills Corporation continuously develops and supplies display manufacturing robots and it plays a significant role in the production of LCD (Liquid Crystal Display) and OLED (Organic Light-Emitting Diode) displays, which are used in various electronic devices such as smart phones, televisions, computer monitors, and more. These robots are used throughout the manufacturing process to improve efficiency, precision, and consistency.

Roles of this Robot in LCD and OLED Manufacturing

Pick-and-Place: Robots are used for the assembly of individual components such as OLED pixels or LCD liquid crystal cells. They pick up components from one location and place them precisely in another, typically at a high speed.

Coating and Deposition: In OLED manufacturing, organic materials are deposited onto substrates to create the organic layers that emit light. Precision is crucial, and robots are used to precisely control the deposition process, ensuring uniformity and consistency.

Glass Substrate Handling: LCD and OLED displays are typically manufactured on large glass substrates. Robots are used to handle and transport these fragile substrates within the production facility. They ensure precise positioning and minimize the risk of damage.

Testing and Inspection: Robots are used for quality control purposes. They can quickly and accurately inspect each display for defects, ensuring that only high-quality products leave the production line.

Photolithography: In LCD manufacturing, photolithography is used to create patterns on the glass substrate. Robots are often used to align masks and substrates accurately, ensuring the patterns are applied correctly.

If you are looking for aautomated transport robots, you can find it on Brils Corporation

Click here to contact BRILS CORPORATION

Post Your Ad Here

Comments