Difference Between Ultra-Supercritical (USC) and Advanced USC (SteamH)

by Rudy P. SysAdmin at howtofindthemoneyDRIVING YOUR PLANT TOWARDS 50% EFFICIENCY.

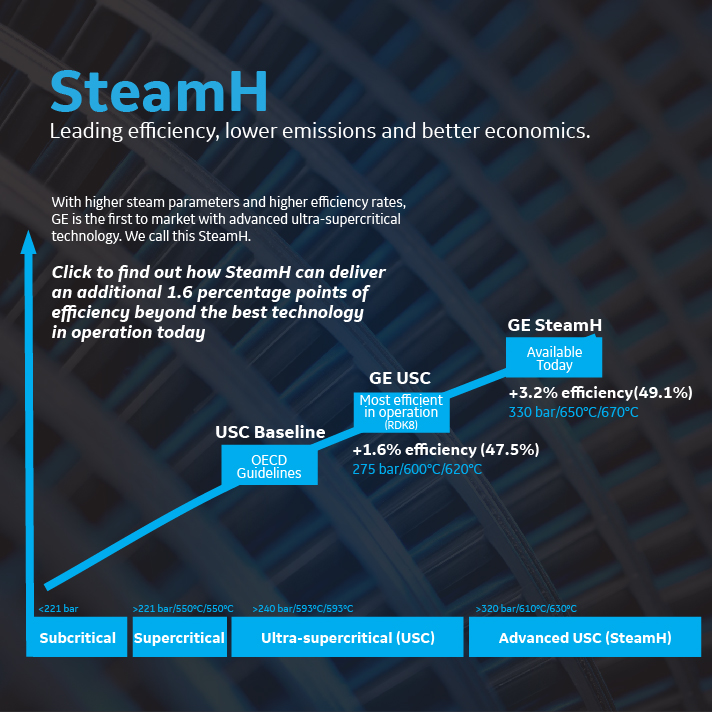

GE is first-to-market with advanced ultra-supercritical technology, and we’re calling it SteamH. GE’s SteamH combines the world’s leading steam plant technology operating at advanced ultra-supercritical conditions with digital power plant software powered by Predix. The result? Our customers are achieving the highest possible efficiency, lowest emissions, and most value over the life of their plant.

The SteamH scope of supply covers a broad range of capacity and configurations to meet customer needs, from individual components to full turnkey plants, between 600-1100MW in size. It is based on GE's proven ultra-supercritical design with key components upgraded. The SteamH portfolio also includes a complete air quality control systems offerings.

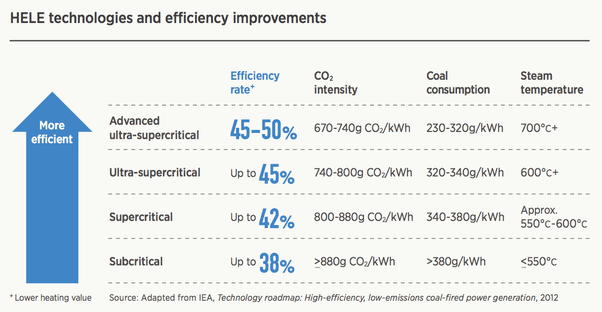

With SteamH, GE can deliver more than 15 percentage points of additional efficiency beyond the global average installed base–driving customers towards 50% efficiency.

Bringing together the physical and digital

SteamH pushes the physical limits of GE’s proven technology with higher steam parameters (reaching 650 ºC), higher efficiency rates, and the best materials that have been proven through more than 30,000 hours of testing in operational ultra-supercritical power plants.

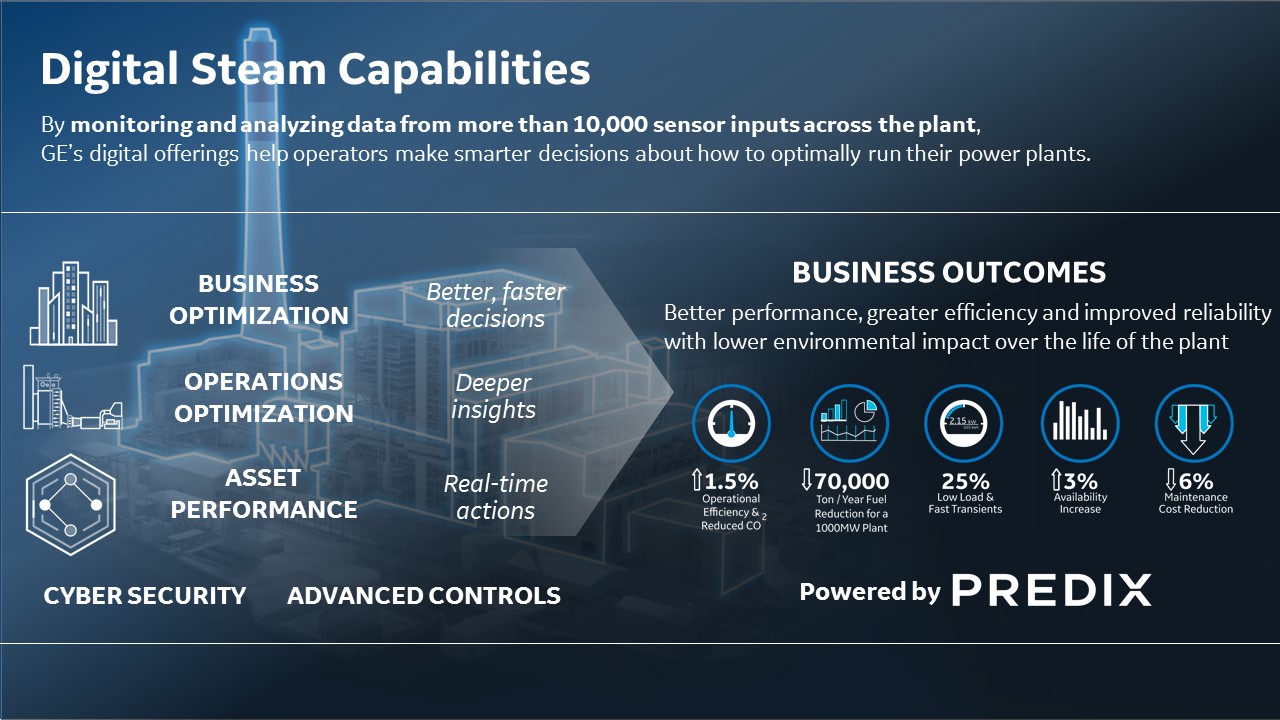

And we’ve paired our industry-leading steam technology with GE’s digital capabilities powered by Predix to deliver better performance, greater efficiencies, and improved reliability—all at a lower cost. By monitoring and analyzing data from more than 10,000 sensor inputs across the plant, GE’s Digital Power Plant for Steam helps plant operators make smarter decisions about how to run their plants.

Providing more value over the life of your plant

SteamH is not just about selling our customers hardware and software—it’s about selling them outcomes, and we guarantee them as part of our new commercial agreements. We call this Guarantees 4.0.

We now offer customers extended guarantees on performance, availability, and reliability made possible by digital solutions. Under this new model, both GE and our customers are invested in the process and share in the success. When our customers win, we win too. And it’s not just for the short term; we can guarantee better outcomes over the life of the plant. Let’s win together.

When comparing ultra-supercritical versus supercritical power plants, SteamH delivers better performance and more value to customers. How much? 1.6% higher efficiency. 99% reliability. 96% availability. 3% CO2 reduction. And ultimately, more profitable growth…adding up to $80M net present value over the life of a 1000 MW power plant.

And when our digital steam solutions are added, the numbers only get more impressive. You can increase operational ultra-supercritical efficiency up to 1.5% over the life of the plant, reduce CO2 emissions by 3%, and allow for 5% less unplanned downtime … adding up to $50M in net present value over the life of the plant.

Meet two companies that have already chosen SteamH

Two of our customers are already pioneering the advanced ultra-supercritical field—and they’re trusting GE to accompany them.

Karaburun by Yildirim

As a pioneer in investing in the future of energy with the best available technology, Turkey’s Yildirim is the first to select GE’s SteamH offerings for the total plant. Yildirim has elected to use SteamH for its 2x800 MW Karaburun Imported Coal Project in Turkey. The scope includes the advanced ultra-supercritical boiler and steam turbine generator combined with digital power plant software.

Dr. Tamer Turna from Yildirim says “Yildirim is proud to be the first power plant owner in the world to select GE’s SteamH technology and software offerings for implementation at our Karaburun plant in Turkey. By combining the most advanced steam technology operating at advanced ultra-supercritical conditions with GE’s digital power plant offerings, GE is guaranteeing us the highest possible efficiency, lowest emissions and most value over the life of the plant. We look forward to working with GE as their first SteamH customer.”

Pingshan II by Huaibei Shenergy Power Generation

Huaibei Shenergy Power Generation Co. Ltd. is the first company to select the most efficient steam boiler technology in the world with steam temperature operating at advanced ultra-supercritical level (630° Celsius) for their power plant Pingshan II. And they trust GE to deliver it! In partnership with Shanghai Electric, GE will manufacture the key components of the boiler including burner, water wall, superheaters and reheaters, directly from its largest and world’s most advanced manufacturing technologies boiler factory – Wuhan Boiler Company.

The 10 largest coal producers and exporters in Indonesia:

Source:  General Electric

General Electric

Sponsor Ads

Created on Jul 8th 2019 06:47. Viewed 1,054 times.

Comments

No comment, be the first to comment.