All You Need to Know About the Rapid Tooling Process

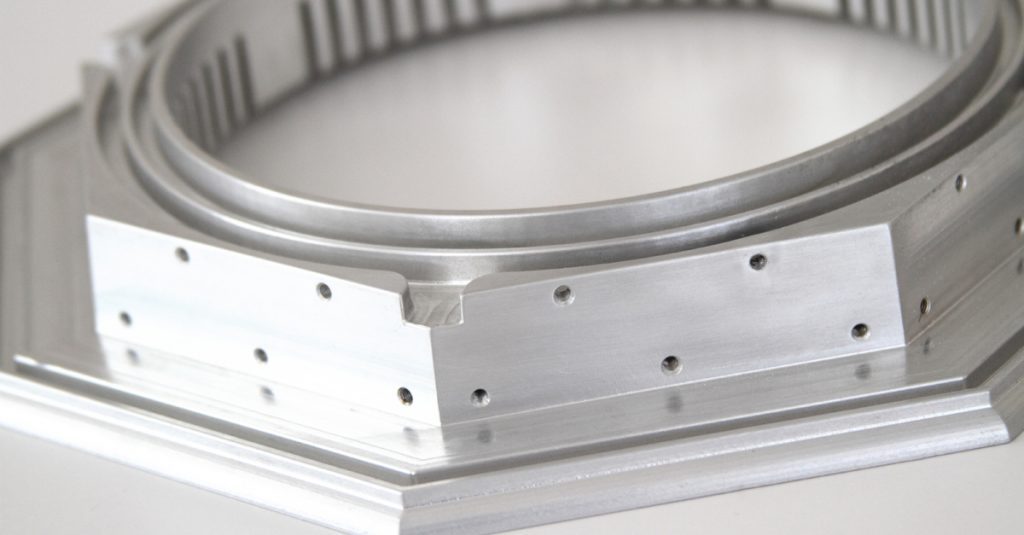

Rapid tooling process is a technique is considered to be combination of conventional tooling methods and rapid prototyping techniques. It is used to produce a mold in the fastest way possible along with parts of model that are derived from CAD data which is cost effective when compared to the traditional methods of machining. This method makes use of rapid prototyping process that is used to fabricate a tool for a limited number of prototypes. The RT process can be categorised as ‘Low Volume’ which includes soft tooling, bridge tooling, and reaction injection molding; ‘Intermediate’ which involves metal filled epoxy tooling and powdered metal tooling and technologies such as space puzzle molding.

Rapid tooling process is a technique is considered to be combination of conventional tooling methods and rapid prototyping techniques. It is used to produce a mold in the fastest way possible along with parts of model that are derived from CAD data which is cost effective when compared to the traditional methods of machining. This method makes use of rapid prototyping process that is used to fabricate a tool for a limited number of prototypes. The RT process can be categorised as ‘Low Volume’ which includes soft tooling, bridge tooling, and reaction injection molding; ‘Intermediate’ which involves metal filled epoxy tooling and powdered metal tooling and technologies such as space puzzle molding.

The tooling cost often turns out to be expensive when the quantity of production is high. Also, businesses need to make sure that tools are produced quickly in an economical manner especially when it comes to the small manufacturing units. Also, the product development cycle requires an immediate tooling mechanism that is used for functional tests, deliver samples for marketing along with the production process design. This process is highly important for the manufacturing industry. One of the major advantages of rapid tooling process is that the tooling time is shorter than the traditional methods. Apart from this, rapid tooling process is effective in the sense that:

- The prototypes build up in little time and makes the process faster

- You get to know about design imperfection during early stages

- The cost of tooling is low which facilitates design modification and refinement

- It makes way for function testing

- The molds used in the process can produce a large number of part

There are constraints associated with the tooling process as well which are as follows:

The rapid RP systems are somewhat too slow and often limited as they cannot produce parts with the wide range of materials at a faster rate. Also, when it comes to fabrication only molding and casting are the two ways that are available. Rapid prototyping make the manufacturing process faster cheaper and better. Moreover, the tooling fabrication is an important application when it comes to direct manufacturing.

There are a different number of paths that can be taken to obtain a functional tool from CAD software the choice for which depends on the factors such as the volume that needs to be produced, the material and accuracy requirements, the objectives, and the applied process. Also, because of the technological inventions there are several other factors as well that might influence the choices.

The process of rapid tooling also provides the customization that is necessary for personal application in order to stay free from trial and error measurements. It makes use of CAD program which is used to make a custom mold in order to fix a problem. The crew members are responsible for determining the type of rapid tool materials that need to be used depending on the demand of the client.

Advertise on APSense

This advertising space is available.

Post Your Ad Here

Post Your Ad Here

Comments